Pressure control system for frequency change compressor in frequency change air conditioner

A technology of frequency conversion compressors and frequency conversion air conditioners, applied in heating and ventilation control systems, heating and ventilation safety systems, refrigerators, etc., can solve the problems affecting the service life of frequency conversion compressors, so as to prolong the service life and reduce the cost of starting and stopping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

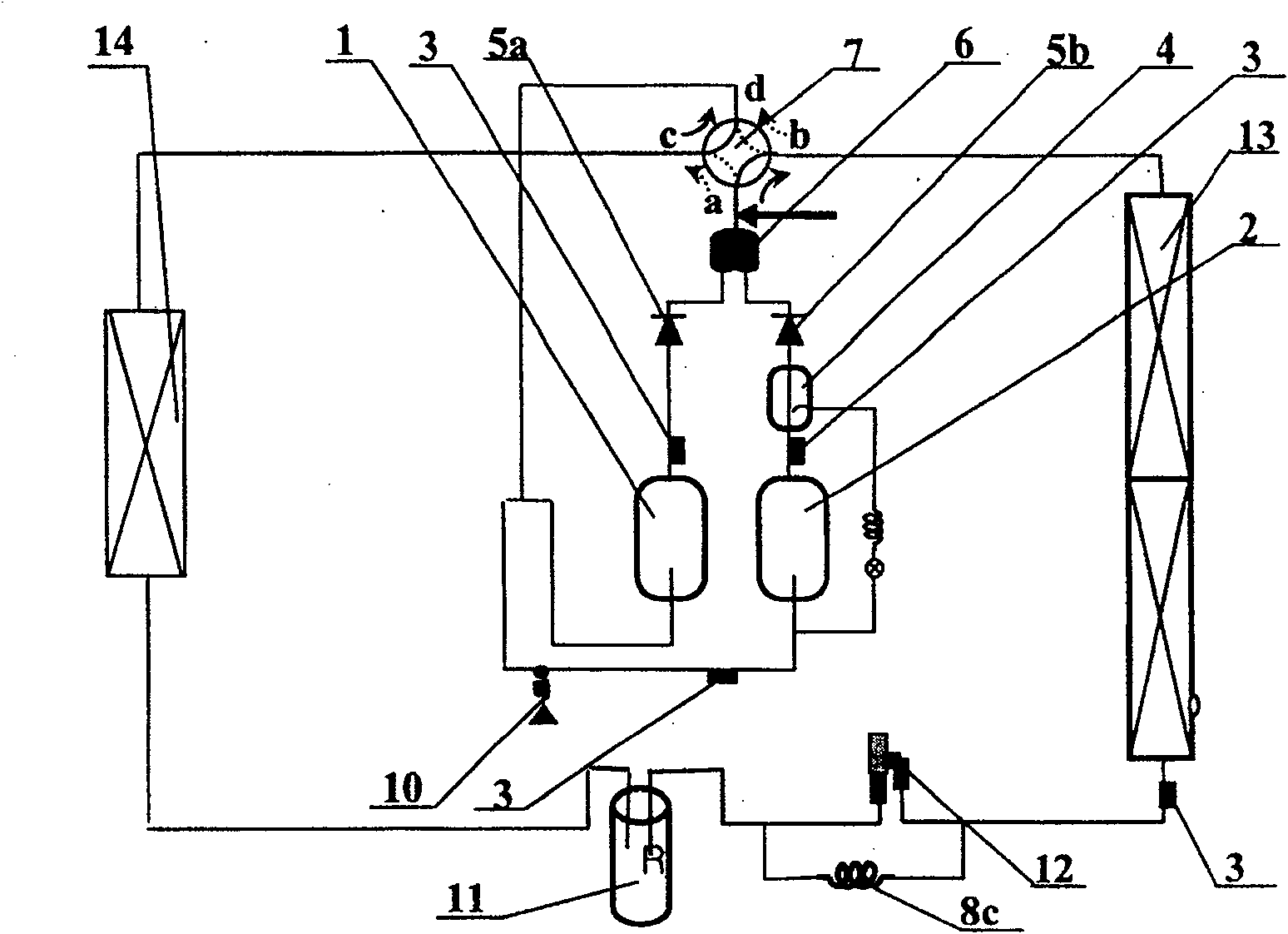

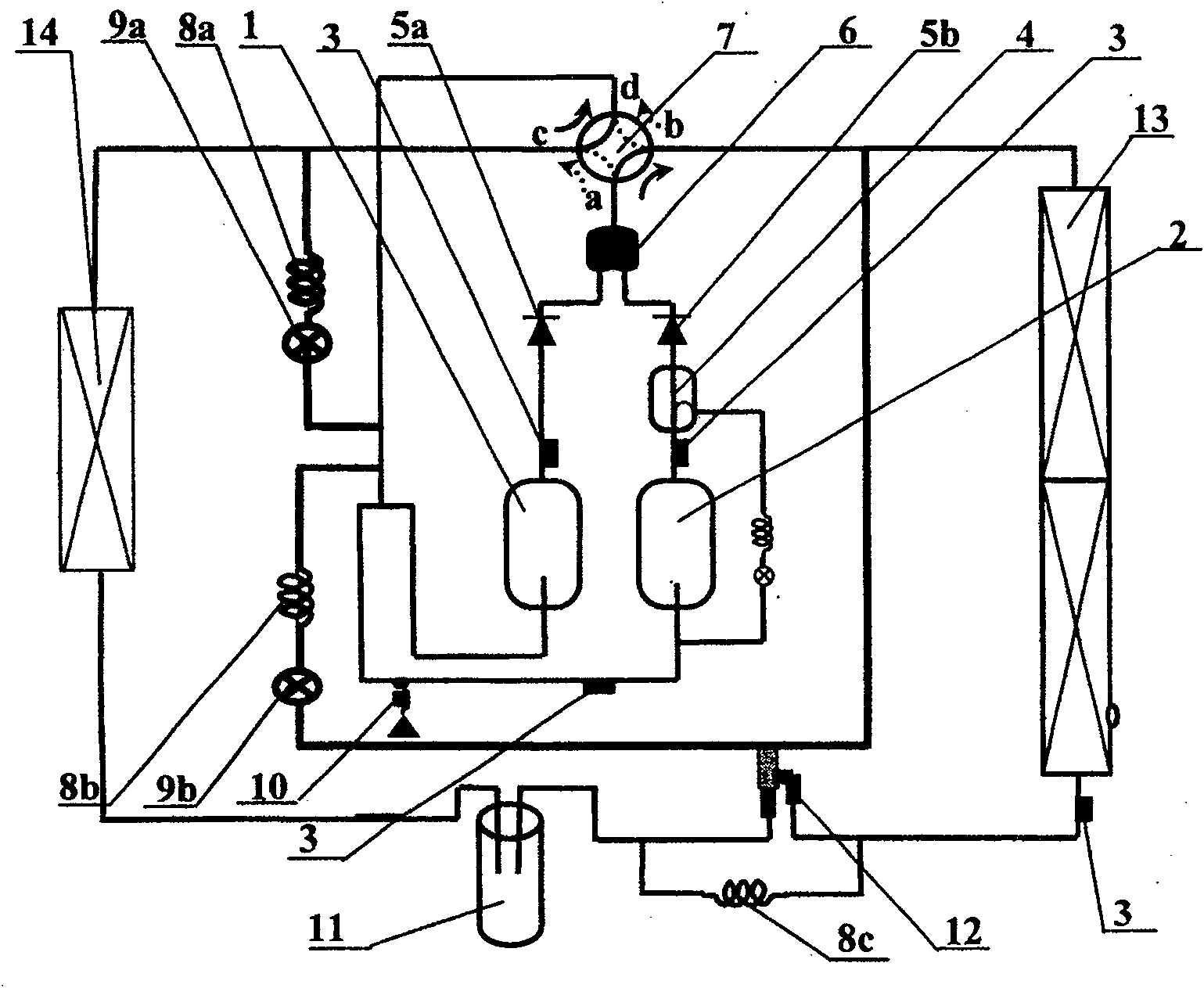

[0021] like figure 2 As shown, the pressure control system for the inverter compressor in the inverter air conditioner includes a fixed-speed compressor 1 and an inverter compressor 2, wherein the output end of the fixed-speed compressor 1 is connected to the high-pressure switch 6 through the first one-way valve 5a, The output end of the frequency conversion compressor 2 is connected to the high-pressure switch 6 through the oil separator 4 and the second one-way valve 5b in turn, the high-pressure switch 6 is connected to the a-end of the four-way valve 7, and the b-end of the four-way valve 7 is connected to the condenser 13, condensing The other end of the device 13 is connected in parallel with the third capillary tube 8c through the electronic expansion valve 12, and then connected with the liquid storage tank 11, and the d end of the four-way valve 7 is respectively connected with the input ends of the fixed speed compressor 1 and the variable frequency compressor 2, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com