Tube jointing structure with locking bar

A connection structure and pipe material technology, which is applied in the direction of socket/socket connection, pipe/pipe joint/fitting, passing components, etc., can solve the problems of long installation and connection time, large shape of connection sleeve, careless installation, etc., to achieve installation and Simple and fast disassembly, reduced disassembly cost, and reduced overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention is described in further detail:

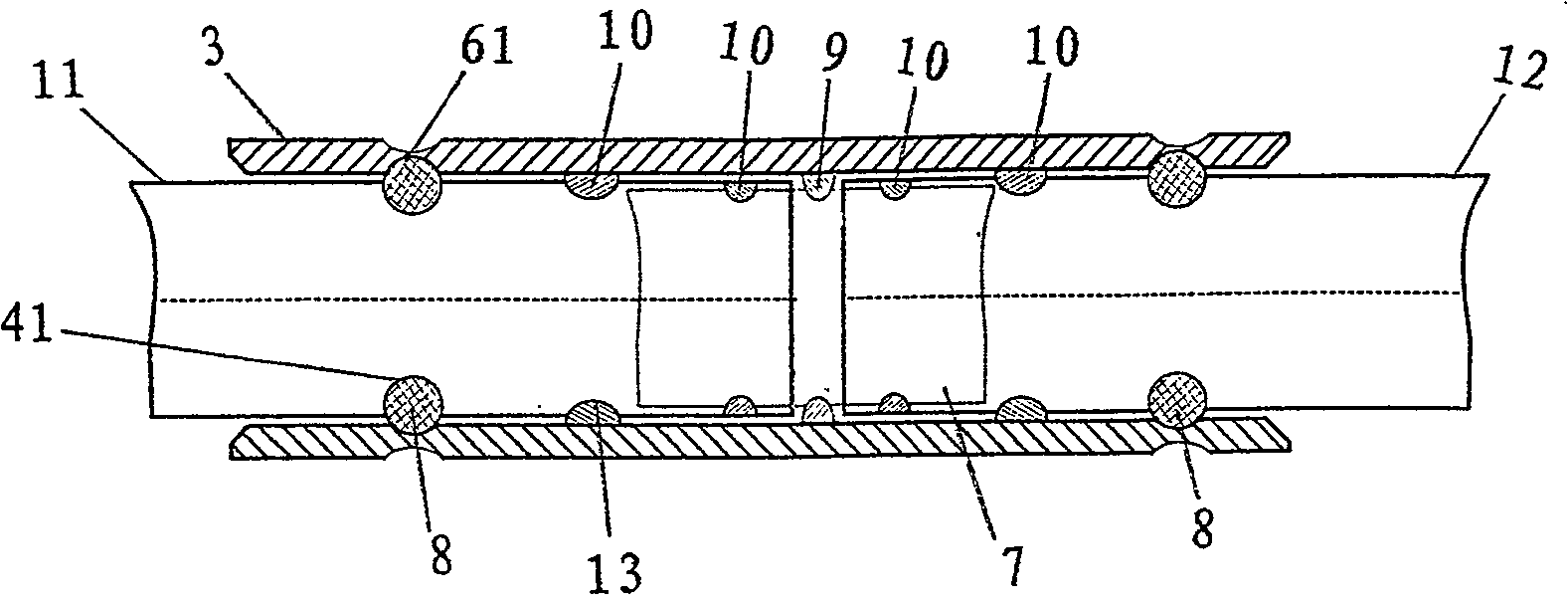

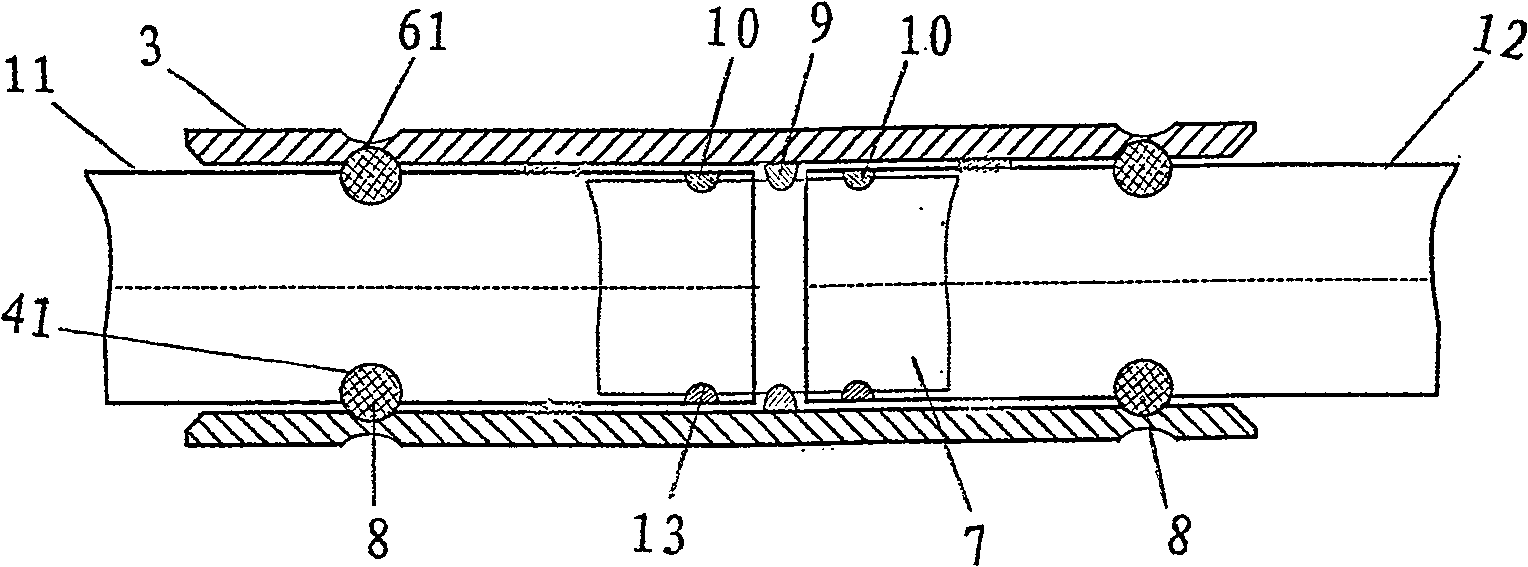

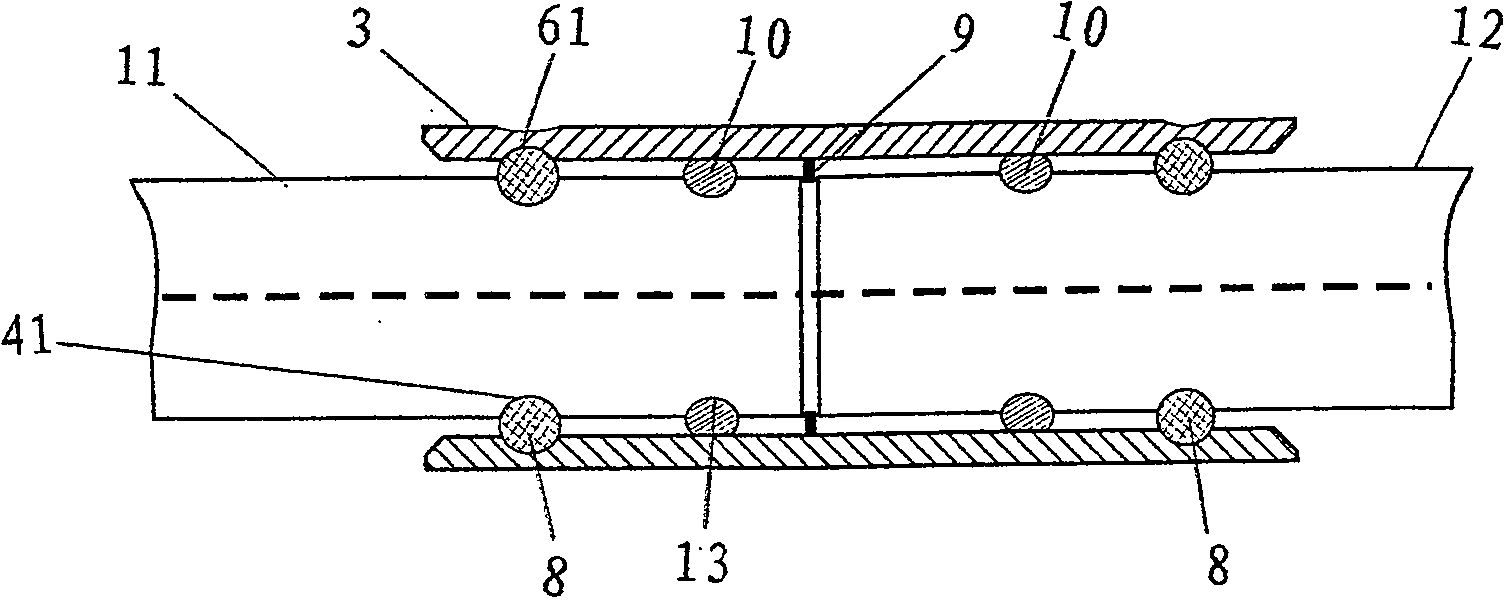

[0020] exist figure 1 , shows the connection structure of pipes with locking strips when the inside and outside are sealed, the two ends of the two pipes 11, 12 to be connected are respectively inserted into the two ends of the inner sleeve 7, and the two ends of the inner sleeve 7 are connected to the two ends of the two pipes 11, 12 to be connected. There is a sealing ring 10 between them, and the sealing ring 10 is set in the sealing ring groove 13 of the inner sleeve 7, and 2, 3 or even more sealing rings 10 can be set to increase the sealing performance. The two ends of the connecting sleeve 3 cover the to-be-connected ends of the two pipes 11, 12, and at the same time, a sealing ring 10 is respectively set between the to-be-connected ends of the two pipes 11, 12 and the two ends of the connecting sleeve 3. 10 is set in the sealing ring groove 13 of the inner sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com