Method for preparing MDG-1 polysaccharide of lilyturf root

A technology of Ophiopogon japonicus polysaccharide, MDG-1, which is applied in the field of preparation of Ophiopogon japonicus polysaccharide MDG-1, can solve the problems of high cost, time-consuming, and inability to adapt to industrial production, and achieve the effect of short time-consuming and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

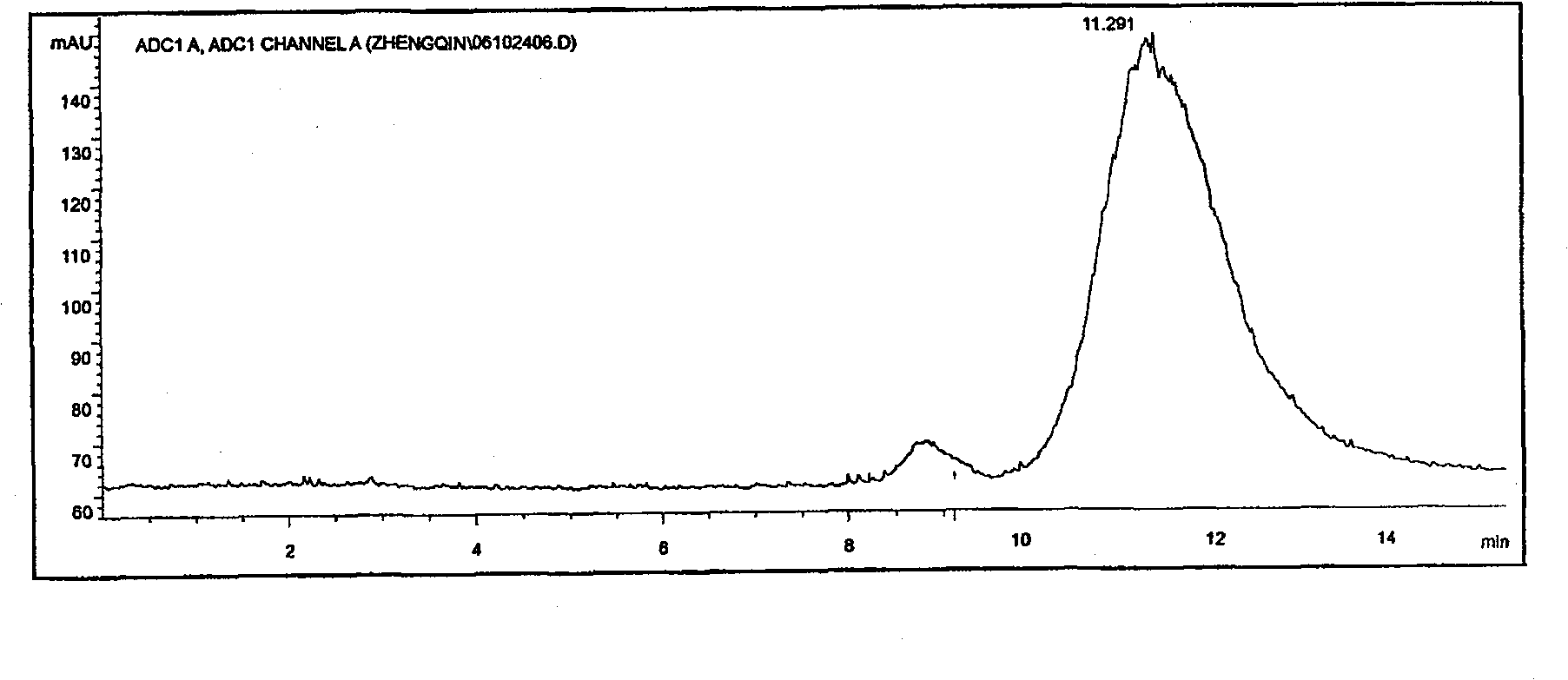

Image

Examples

Embodiment 1

[0021] Embodiment 1 (preparation of Ophiopogon japonicus polysaccharide MDG-1)

[0022] 1. Extraction of Ophiopogon japonicus polysaccharide

[0023] Weigh 20kg of dried Ophiopogon japonicus roots, extract 10 times the amount with water for 3 times, each time for 30 minutes, and extract the dregs with water twice. Combine the water extracts and concentrate them under reduced pressure to 1g / ml, add 95% ethanol until the alcohol content reaches 70%, let stand overnight, pour off the supernatant, repeat the precipitation with alcohol once, and freeze-dry to obtain light yellow Ophiopogon japonicus crude polysaccharide powder.

[0024] 2. Ultrafiltration separation of Ophiopogon japonicus polysaccharide

[0025] Dilute the crude polysaccharide of Ophiopogon japonicus 15 times, use a flat ultrafiltration membrane with a molecular weight cut-off of 10,000 and the material is cellulose acetate for ultrafiltration, the ultrafiltration pressure is 0.3MPa, and the ultrafiltrate is con...

Embodiment 2

[0031] Embodiment 2 (preparation of Ophiopogon japonicus polysaccharide MDG-1)

[0032] 1. Extraction of Ophiopogon japonicus polysaccharide

[0033] Weigh 20kg of dried Ophiopogon japonicus roots, extract 8 times the amount with water for 3 times, each time for 30 minutes, and extract the dregs with water for 3 times. Combine the water extracts and concentrate them under reduced pressure to 0.5g / ml, add 75% ethanol until the alcohol content reaches 60%, let it stand overnight, pour off the supernatant, repeat the precipitation with alcohol once, and freeze-dry to obtain light Yellow Ophiopogon japonicus polysaccharide powder.

[0034] 2. Ultrafiltration separation of Ophiopogon japonicus polysaccharide

[0035] Dilute the Ophiopogon japonicus crude polysaccharide 15 times, use a hollow fiber ultrafiltration membrane ultrafiltration with a molecular weight cut-off of 10,000 and the material is polyamide, and the pressure is 0.1MPa. The ultrafiltrate is concentrated at 70°C a...

Embodiment 3

[0041] Embodiment 3 (preparation of Ophiopogon japonicus polysaccharide MDG-1)

[0042] 1. Extraction of Ophiopogon japonicus polysaccharide

[0043]Weigh 20kg of dried Ophiopogon japonicus tuber, extract 12 times the amount with water for 3 times, each time for 30 minutes, and extract the dregs with water for 2 times. Combine the water extracts and concentrate them under reduced pressure to 0.75g / ml, add 95% ethanol until the alcohol content reaches 80%, let stand overnight, pour off the supernatant, repeat the precipitation with alcohol once, and freeze-dry to obtain light Yellow Ophiopogon japonicus polysaccharide powder.

[0044] 2. Ultrafiltration separation of Ophiopogon japonicus polysaccharide

[0045] Dilute the crude polysaccharide of Ophiopogon japonicus 15 times, use a tubular membrane ultrafiltration with a molecular weight cut-off of 10,000 and the material is sulfonated polysulfone, the pressure is 0.2MPa, and after the ultrafiltrate is concentrated at 70°C, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com