Circular lighting device and its manufacturing method

A technology for lighting devices and manufacturing methods, applied in lighting devices, components of lighting devices, cooling/heating devices for lighting devices, etc., can solve the problem of poor electrical contact between LED wires and printed wiring boards, and the inability to easily manufacture rings Shaped lighting devices, high installation density and other issues, to achieve the effect of preventing poor electrical contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

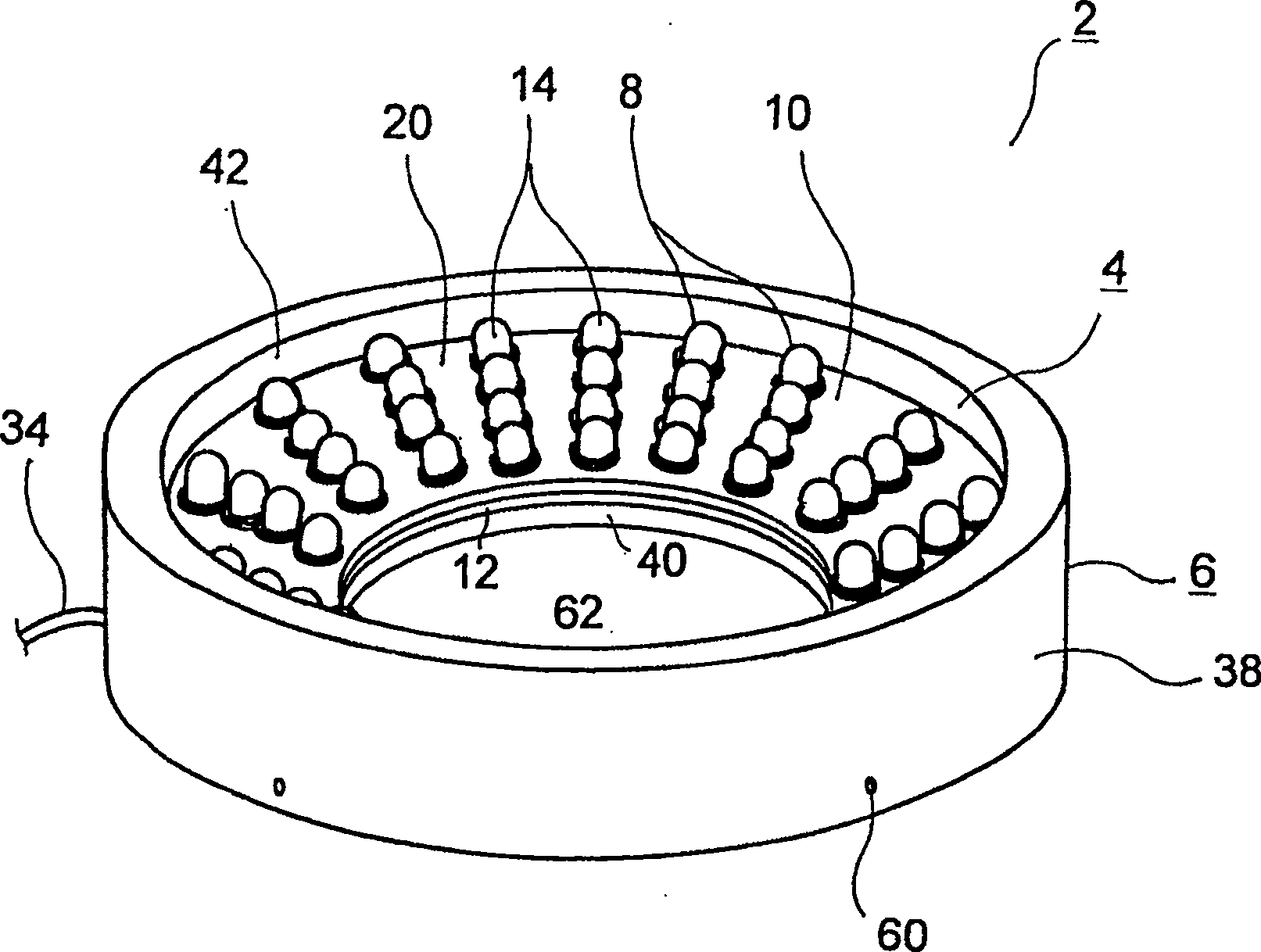

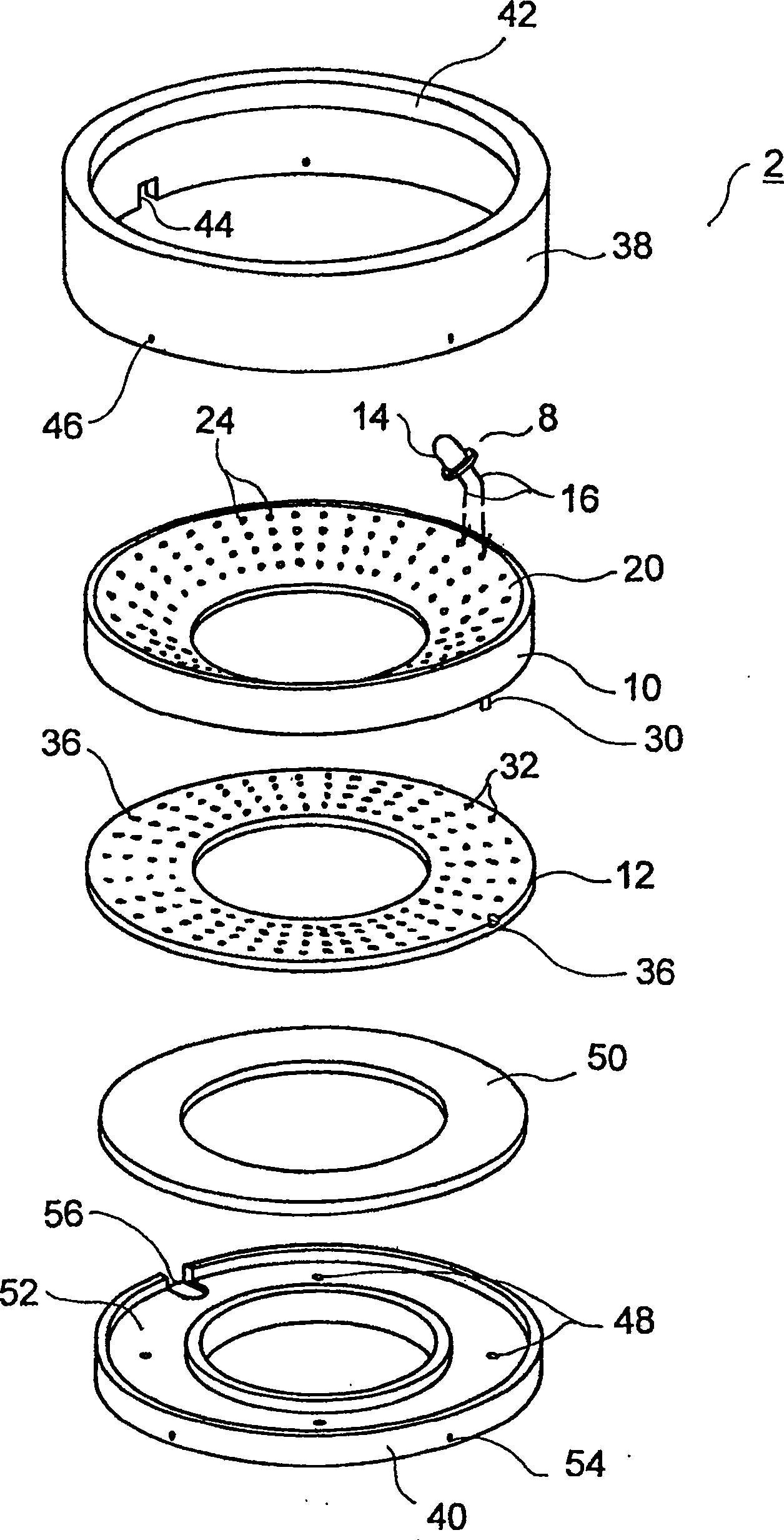

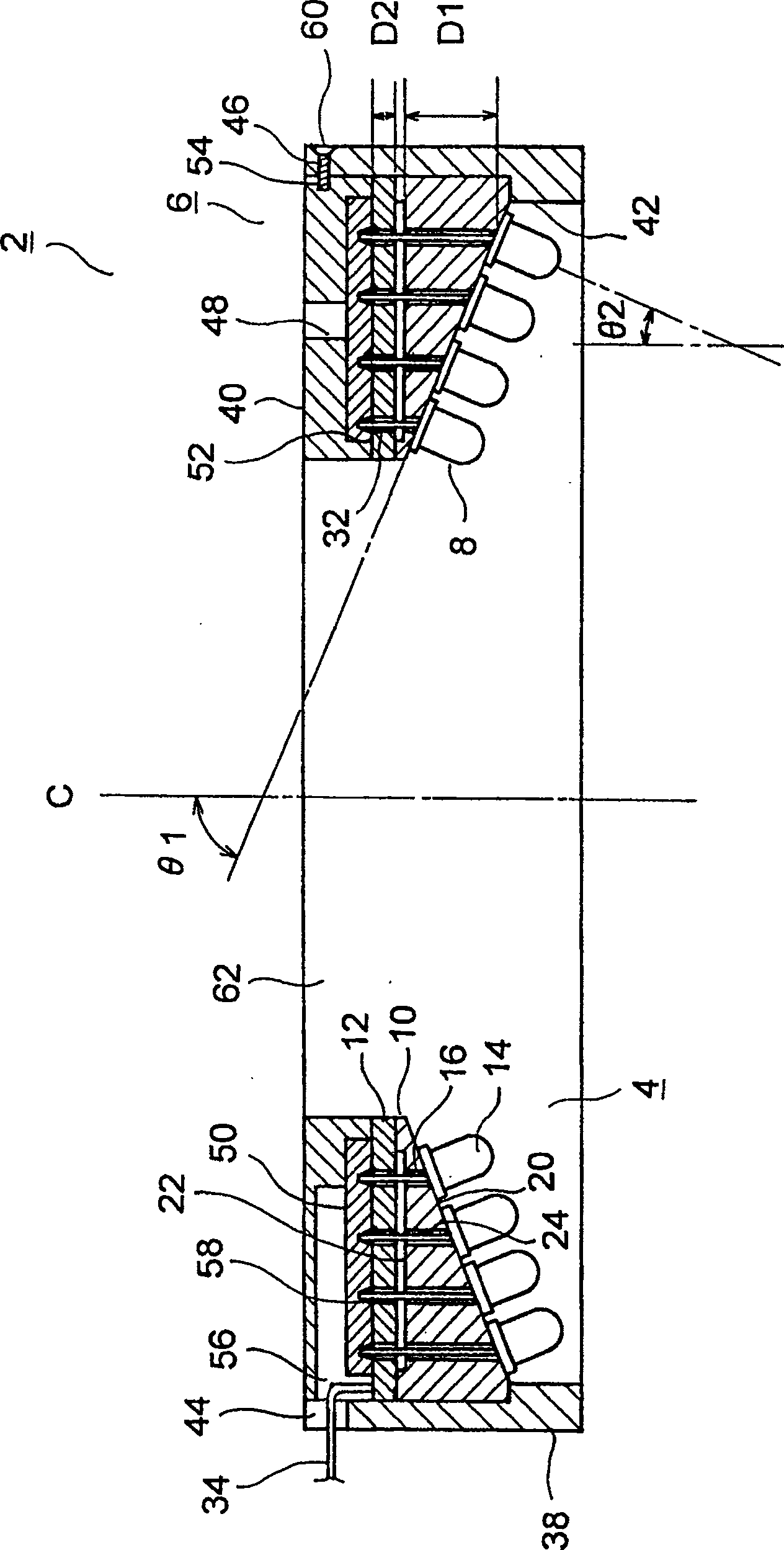

[0030]Hereinafter, various embodiments of the ring lighting device and its manufacturing method according to the present invention will be described with reference to the drawings. figure 1 is a perspective view showing the ring lighting device according to the first embodiment of the present invention, figure 2 yes means figure 1 An exploded perspective view of the ring lighting device, image 3 yes figure 1 A schematic cross-sectional view of the ring lighting device, Figure 4 yes means image 3 An enlarged cross-sectional view of the through-hole of the platen and its surrounding structure.

[0031] exist Figure 1 to Figure 4 In the figure, the illustrated ring lighting device 2 includes a ring light source 4 that irradiates light in a ring shape, and a housing 6 for holding the ring light source 4 . Hereinafter, each of these constituent elements will be described in detail.

[0032] The annular light source 4 includes a plurality of LEDs 8 , an annular base 10 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com