Dielectric substrate integrated waveguide slot array antenna

A slot array antenna, dielectric substrate technology, applied in slot antennas, antennas, antenna arrays and other directions, can solve the problems of high processing cost, high antenna cost, increased mechanical cost, etc., to improve directional radiation capability, cross-polarized electrical The effect of low level and high manufacturing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

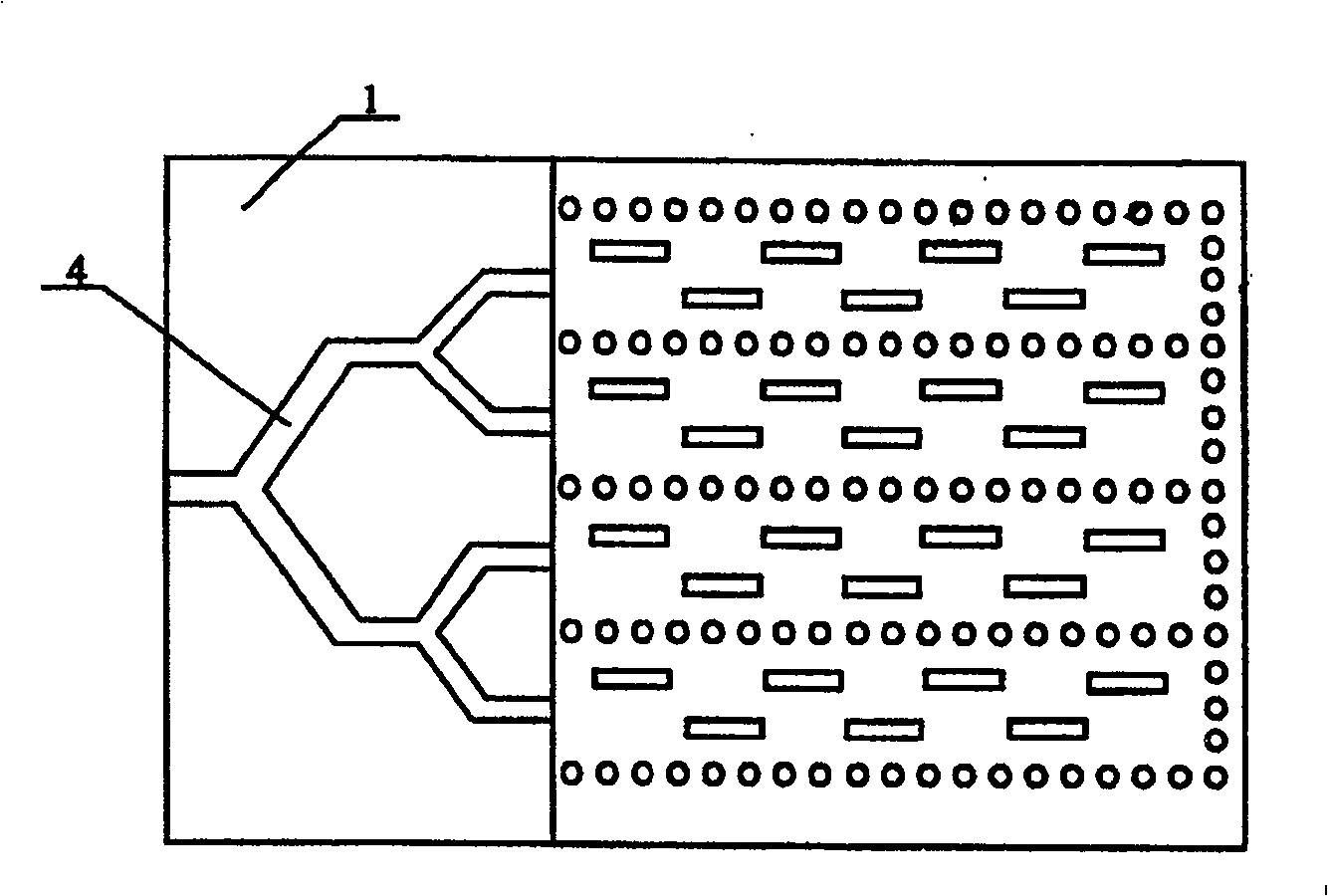

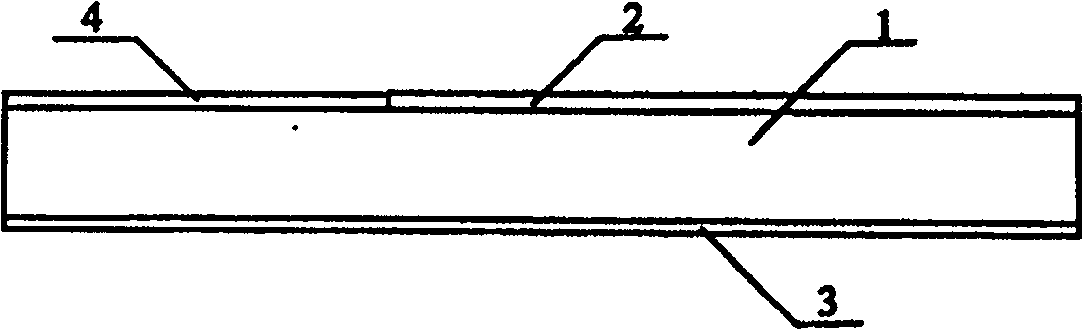

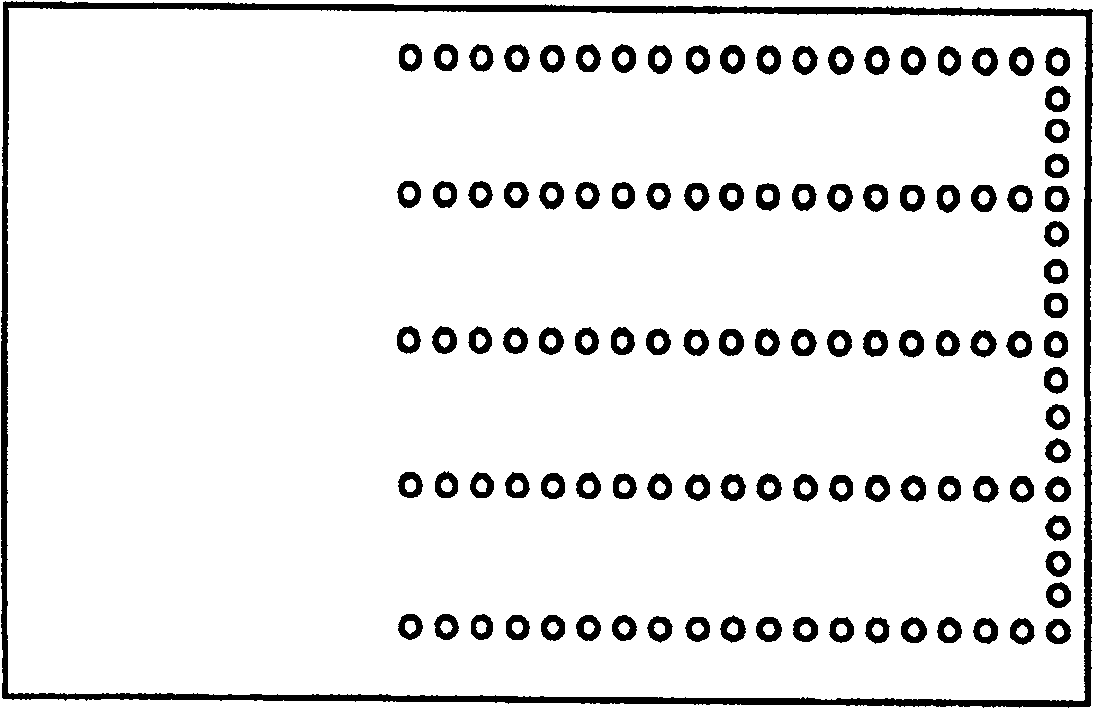

[0023] A dielectric substrate integrated waveguide slot array antenna for electronic equipment such as wireless communication, radar, electronic navigation and electronic countermeasures, including a dielectric substrate plate 1, wherein a complete metal foil 3 is provided on the back of the dielectric substrate plate 1, A slot array 2 and a microstrip power divider 4 are etched on the front metal foil, the slot array array 2 is connected to the microstrip power divider 4, and an intercommunication through hole 5 is provided in the dielectric substrate plate 1, and the through hole 5 The metallized through holes are arranged in a "U" shape, and the metallized through holes arranged in a "U" shape surround the slot array unit.

Embodiment 2

[0025] This embodiment implements the dielectric substrate integrated waveguide slot array antenna described above at 10 GHz. The dielectric length of the dielectric substrate is equal to 2.4, the thickness is 1.5 mm, and the loss tangent is less than one thousandth. The diameter of the metal through hole used to form the dielectric integrated waveguide is 1 mm, the distance between the through holes is 2 mm, the width of the dielectric substrate integrated waveguide is 12.46 mm, and the distance between adjacent dielectric substrate integrated waveguides is 2.54 mm. The width of the microstrip line is 2.4mm, and the power divider is divided into two stages, one divided into two, and two divided into four. The length of the branch line is 5.40mm, and the width is equal to 1.19mm.

[0026] A total of 16 slits of 4X4 are etched on the metal surface of the dielectric substrate. The length of each slot and the displacement relative to the centerline of the waveguide can be seen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com