Measurement instrument and method suitable for remotely monitoring crack width of concrete

A crack width, remote monitoring technology, applied in the direction of measuring devices, radio wave measuring systems, instruments, etc., can solve the problems of low measurement efficiency, poor real-time performance, inability to monitor crack width and image data dangerous cracks in real time, and reduce labor costs. Strength, good real-time performance, reduce the effect of on-site measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Combine now Figure 2-Figure 14 The present invention is described further:

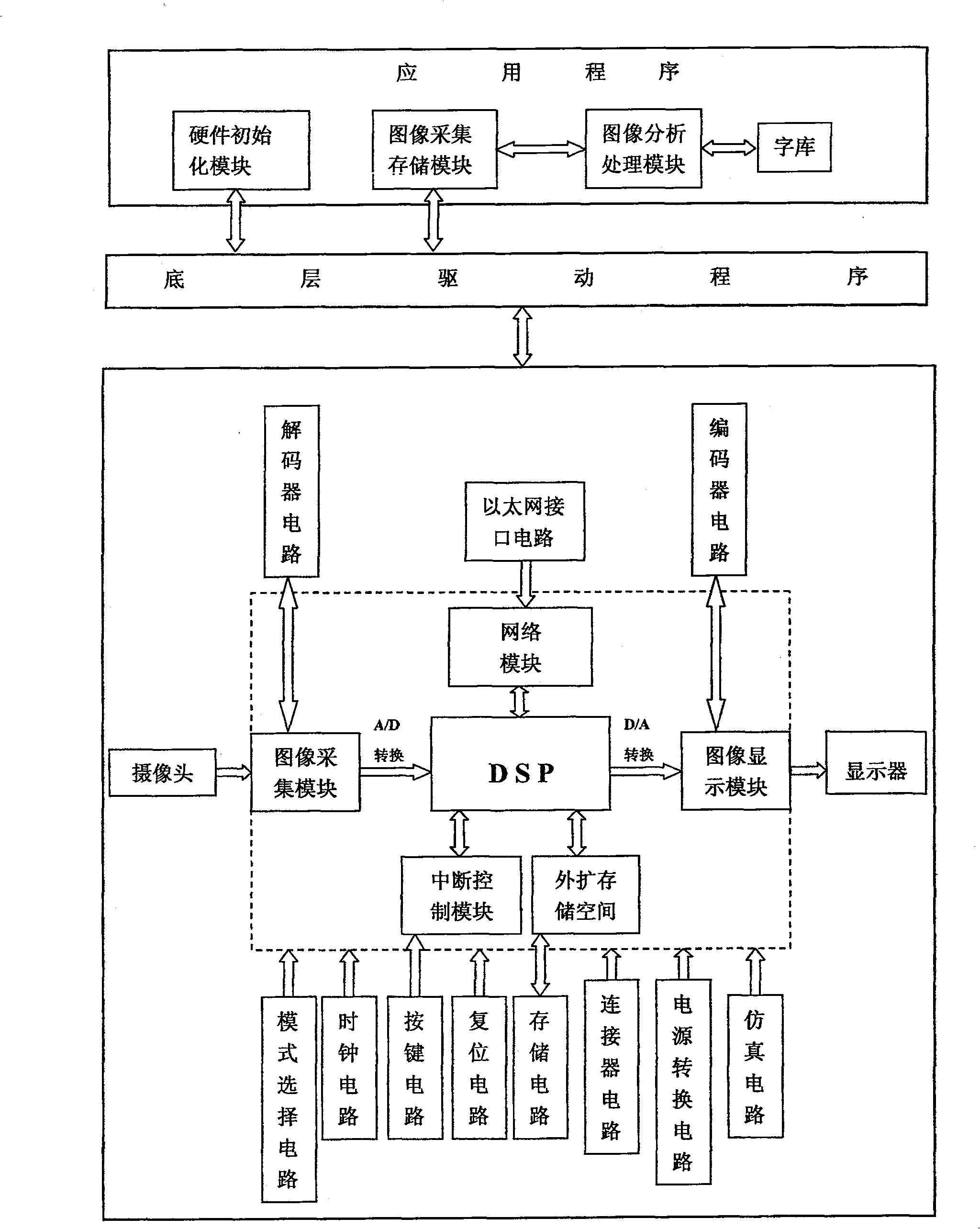

[0025] A concrete crack width measuring instrument with a digital signal processor (DSP) as the core and an automatic interpretation function. The whole instrument includes a camera, an image acquisition module, a DSP, a network module, an image display module, a network interface circuit, a reset circuit, Simulation circuit, button circuit, clock circuit, storage circuit, mode selection circuit, power conversion circuit, connector circuit and display.

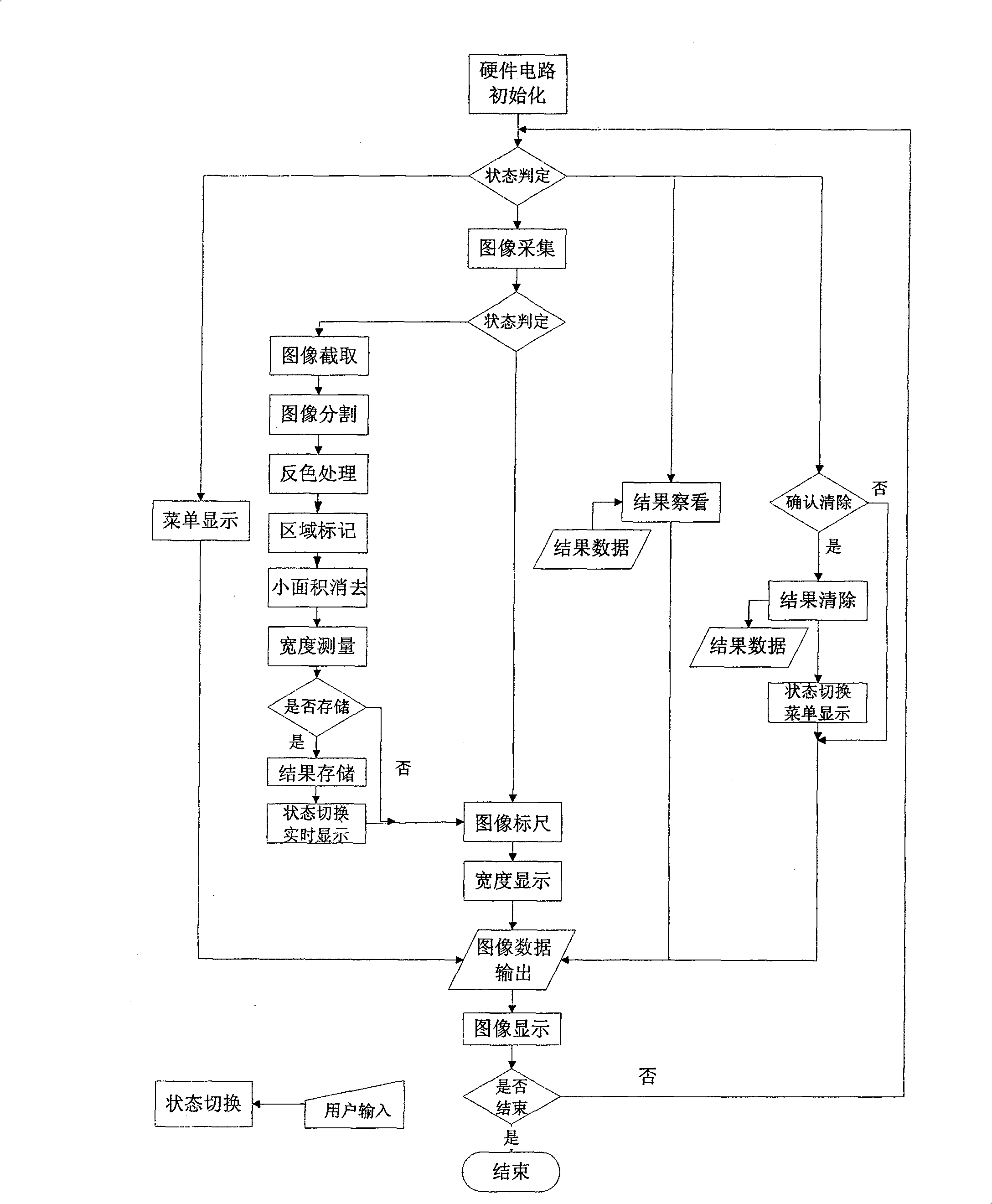

[0026] refer to figure 2 , The automatic interpretation function of the measuring instrument is realized through relevant image processing methods. The first step: image capture. This function is to center the crack image of 720×576 pixels with the cross ruler so that the image is located in the center of the display screen, and then intercept a crack image area of 300×576 pixels (150 pixels left and right with the crack as the center) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com