Hydraulic self-control brake device

A brake device, hydraulic technology, applied in the direction of mining fluid, axial brake, mechanical equipment, etc., can solve the problems of waste of manpower, difficult operation, inaccurate brake positioning, etc., to improve safety management level and reduce oil well failure The effect of reducing the difficulty of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

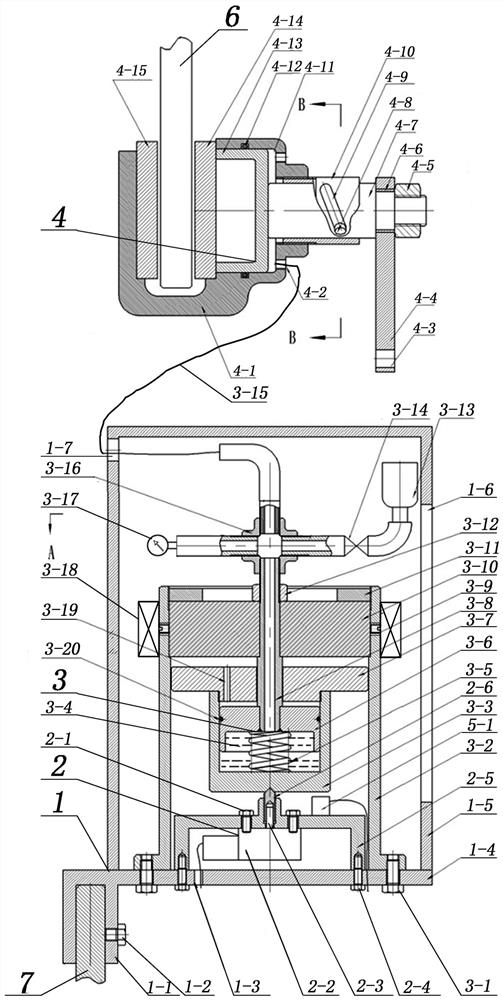

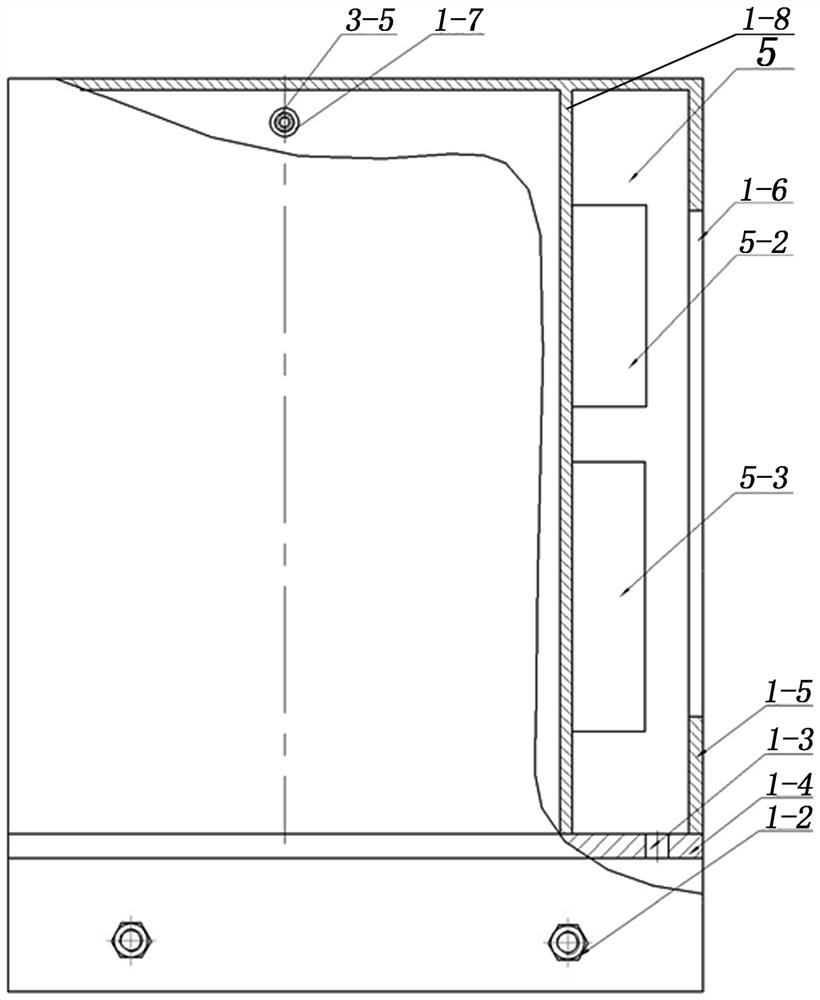

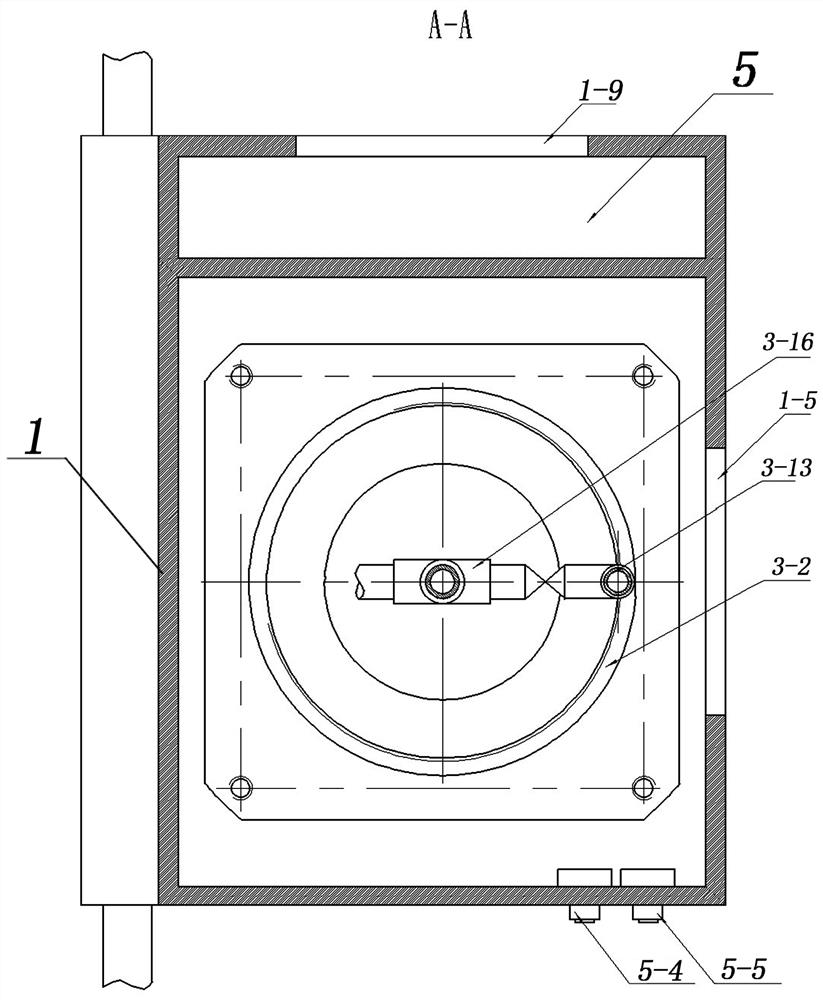

[0038] A hydraulic self-control brake device, which installs the "U" splint 1-1 of the box body 1 on the side vertical plate 7 of the pumping unit support, and fastens it with the jacking bolts Ⅰ1-2, without welding and causing no friction. The unfavorable effect of the structure of the pumping unit not only replaces all the functions of the original brake, but also realizes automatic control, and the position of stopping the well can be preset through the three-speed switch. The working process is as follows:

[0039] 1. During remote shutdown, the production command center sends a well shutdown command, which is transmitted to the oil well RTU through the communication network, and the RTU will send a pulse signal to the input terminal X1 of the PLC circuit control board 5-3, and the PLC circuit control board 5-3 enters the shutdown program , start to monitor the bottom dead point signal preset by the three-speed transfer switch, the delay point signal after the bottom dead p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com