Drive system for chain sprockets of chain drives

A technology of driving device and chain transmission, which is applied in the direction of transmission device, transmission device control, gear transmission device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

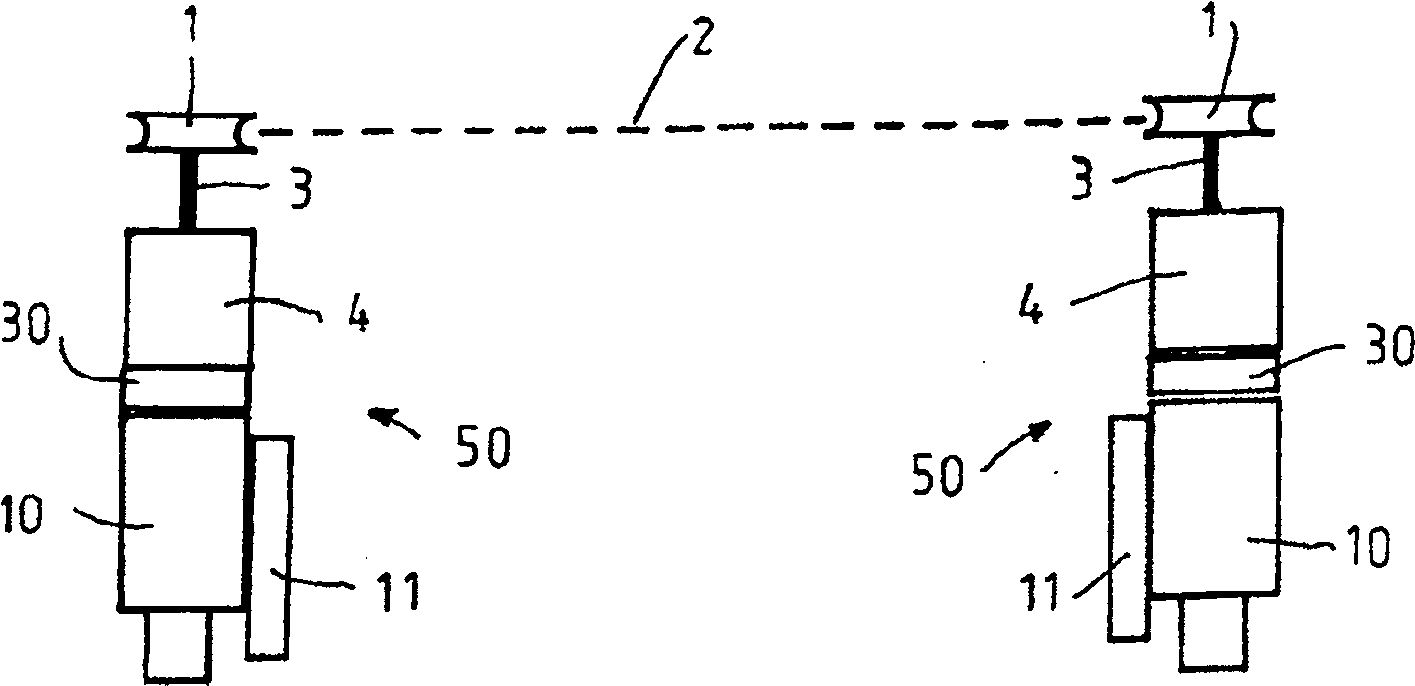

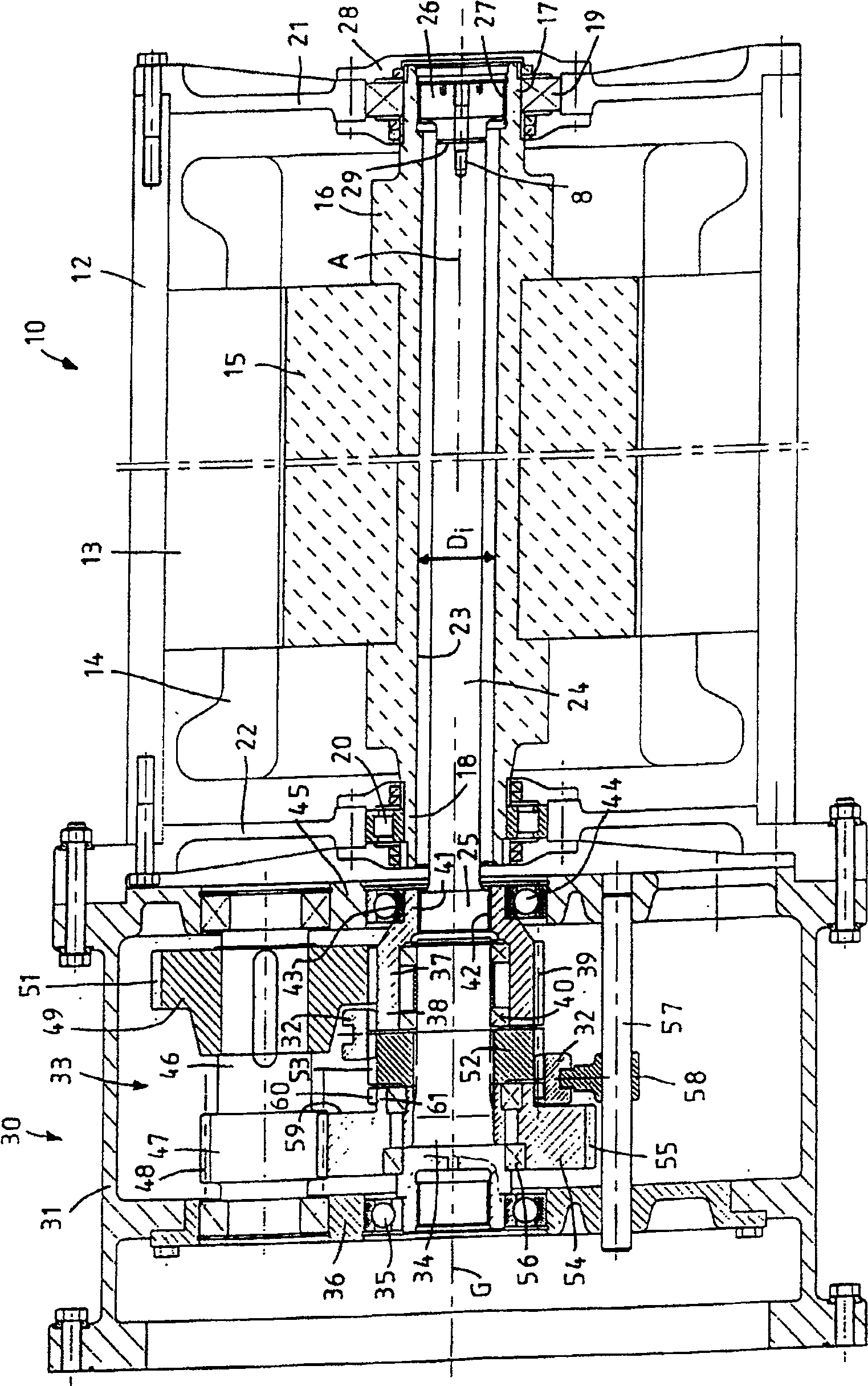

[0020] figure 1Two chain drives, indicated generally at 50, are shown for driving a continuous chain 2 which runs around two sprockets 1 of the chain drive 50, on a working face or roadway formed as a chain scraper conveyor In the case of a conveyor the chain consists of its scraper conveyor, while in the case of a plow it is a plow chain which moves the plow (not shown) along the working face. The sprocket 1 is responsible for the deflection of the chain 2 and is driven in each case by a drive unit, to which the sprocket is connected in a rotationally fixed manner via a sprocket shaft 3 . The drive unit of the two chain drives 50 consists of an electric AC asynchronous motor consisting of a variable frequency motor 10 with a combined switch box 11 for the frequency converter line, which is connected in the middle with the condition of a cantilever transmission 30 The lower is coupled with the overload protection and load balancing reducer 4. The overload protection and load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com