Condensing unit, pressure roller unit and drawing unit

A technology of compressor unit and compacting roller, which is applied in drafting equipment, spinning machine, textile and papermaking, etc., can solve the problem of positioning limitation of the drafting system of the compressor unit, and achieve the effect of stable implementation and stable spinning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

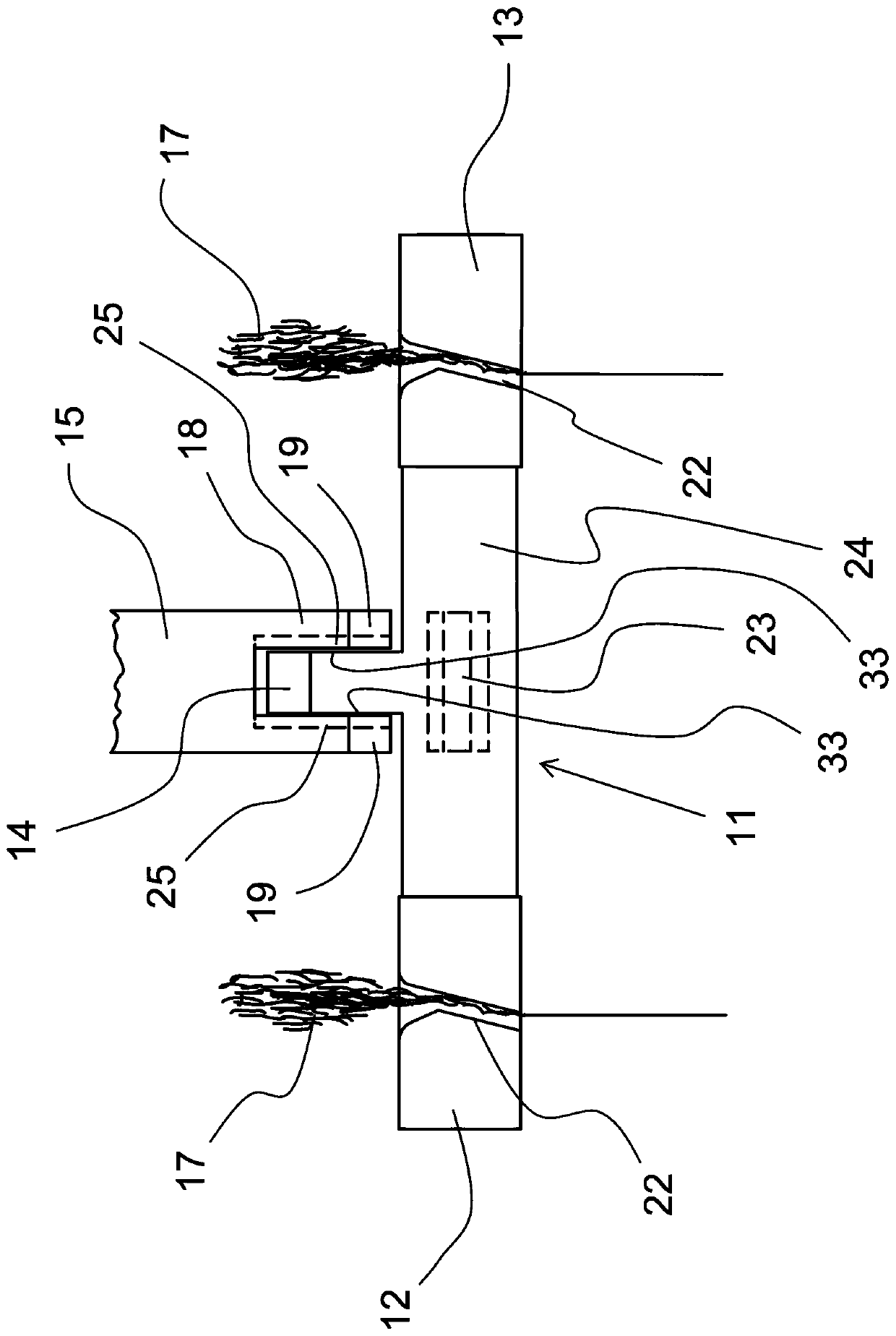

[0032] In the following description of the illustrated alternative embodiments, identical and / or at least equivalent features with regard to the design and / or mode of action of these embodiments are provided with the same reference numerals. If these features are not specifically explained again, their design and / or mode of operation correspond to those of the features already described.

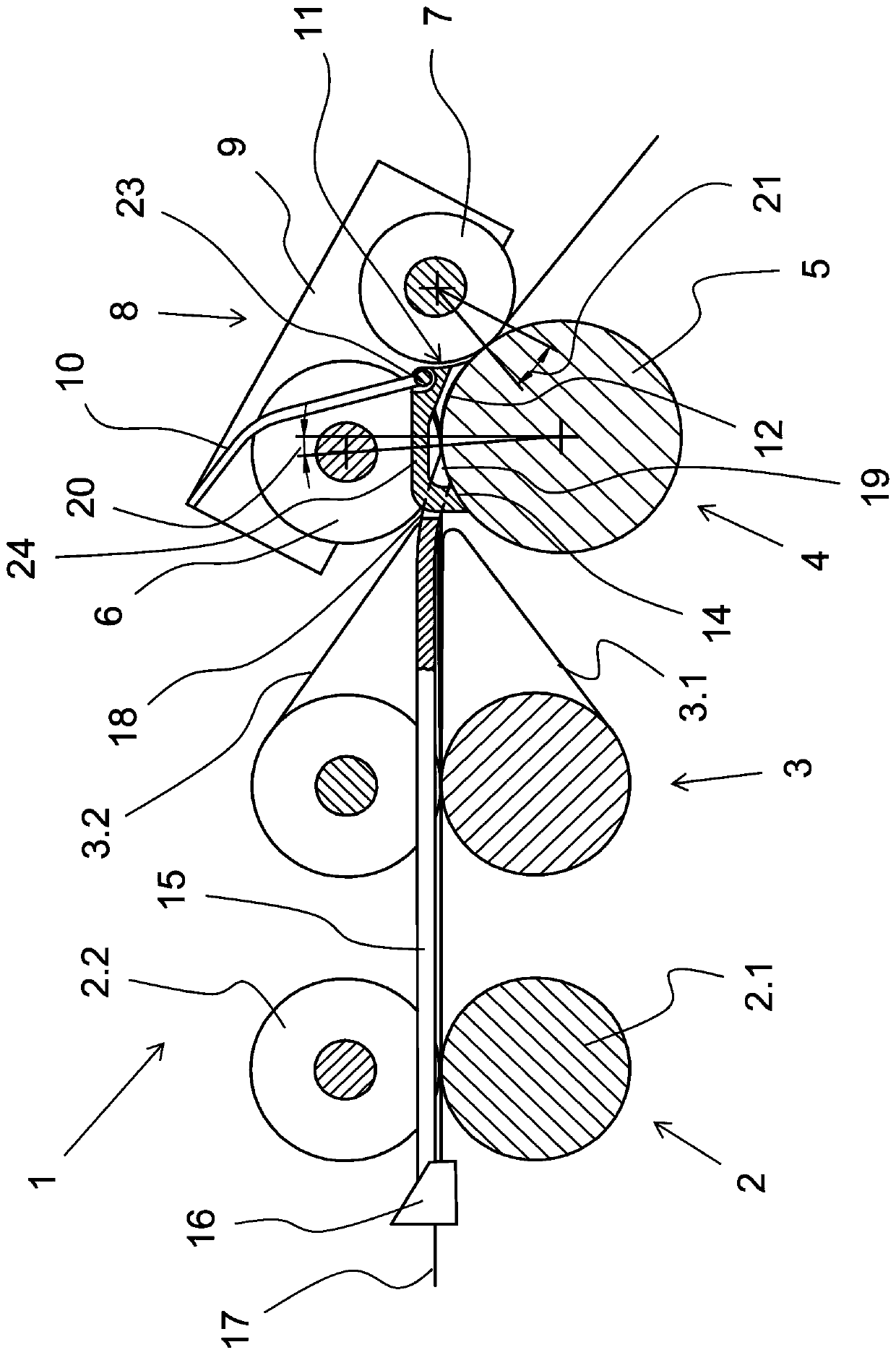

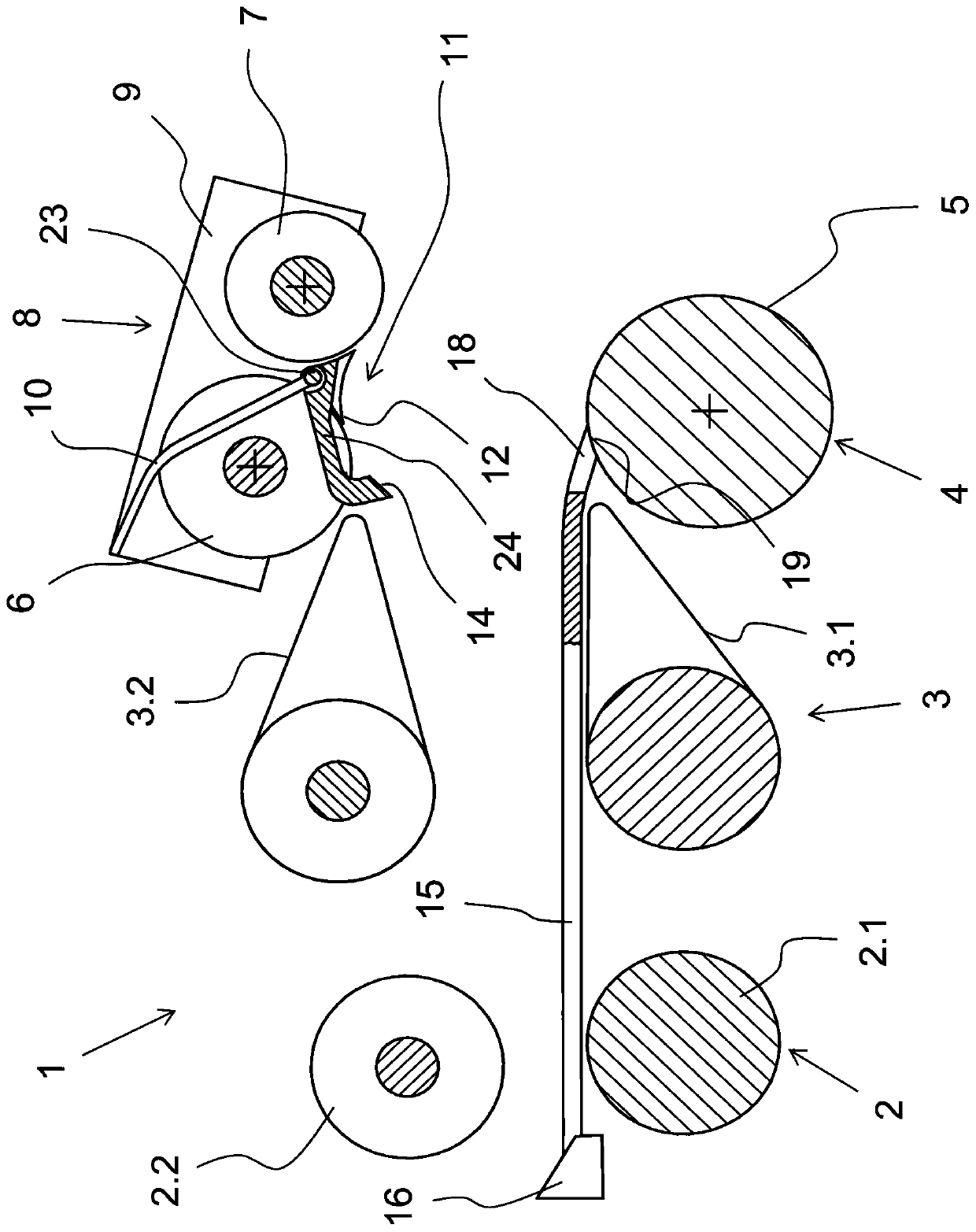

[0033] figure 1 A longitudinal section through a closed drafting system 1 according to the invention is shown. The drafting system 1 has a pair of input rollers 2 , a pair of drafting belts 3 and an output roller 4 . In the delivery roller 4 , the pressing roller 6 and the extraction roller 7 are arranged on the lower drafting roller 5 . In the closed drafting system 1 , the upper roller 2.2 of the input roller pair 2 , the upper belt 3.2 as well as the pressure roller 6 and the extraction roller 7 are located on the bottom roller 2.1 , the belt 3.1 and the drafting roller 5 .

[0034] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com