Electrochemistry test method used for rotary type single-phase flow erosion testing

A test method, electrochemical technology, applied in the direction of measuring devices, scientific instruments, weather resistance/light resistance/corrosion resistance, etc., can solve the problems that the experimental results are difficult to promote engineering applications, the test time of related equipment is long, and the mechanism is not deep enough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

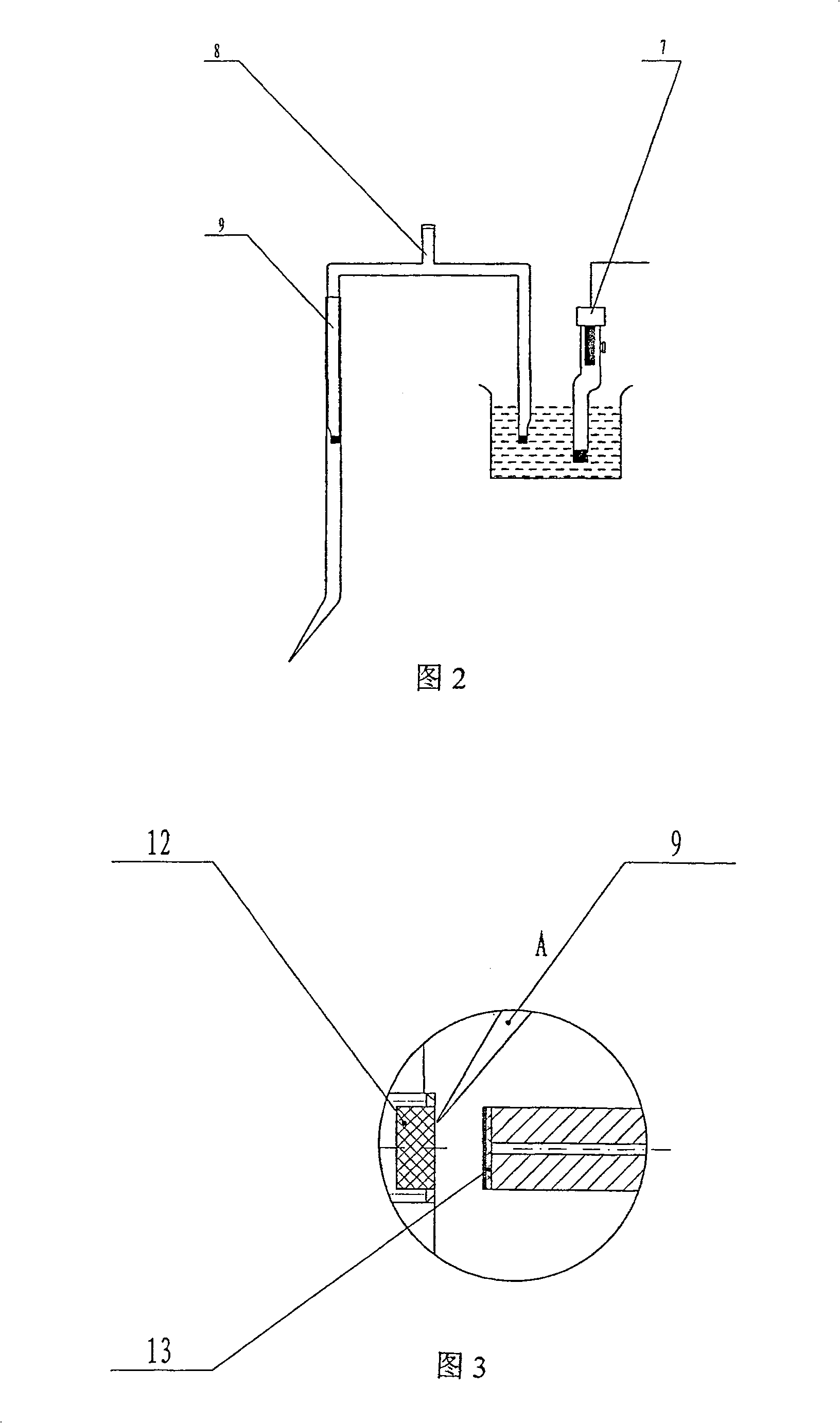

[0030] like figure 1 As shown, the rotary single-phase flow erosion test device includes a working electrode 12, a Lujin capillary 9, a salt bridge 8, a reference electrode 7, an auxiliary electrode 13, a copper ring-carbon brush 4, a potentiostat 11, and an industrial computer 6 . The transmission shaft 2 is equipped with a rotating disk 10, the workpiece to be measured is used as a working electrode, and its outer surface is flush with the inner wall of the upper liquid container 3. The working electrode 12 and the auxiliary electrode 13 coated with a layer of stainless steel or platinum on the side of the rotating disk On the same horizontal plane; the sides of the rotating disc are respectively opened at 0°, 90°, 180°, and 270°, and the wires pass through the holes of 0°, 90°, 180°, and 270° respectively and meet at the rotating disc One end of the central hole of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com