Automatic clutch for motorcycle

A technology for automatic clutches and vehicles. It is applied in automatic clutches, clutches, mechanical drive clutches, etc., and can solve the problems of low transmission efficiency and poor automatic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

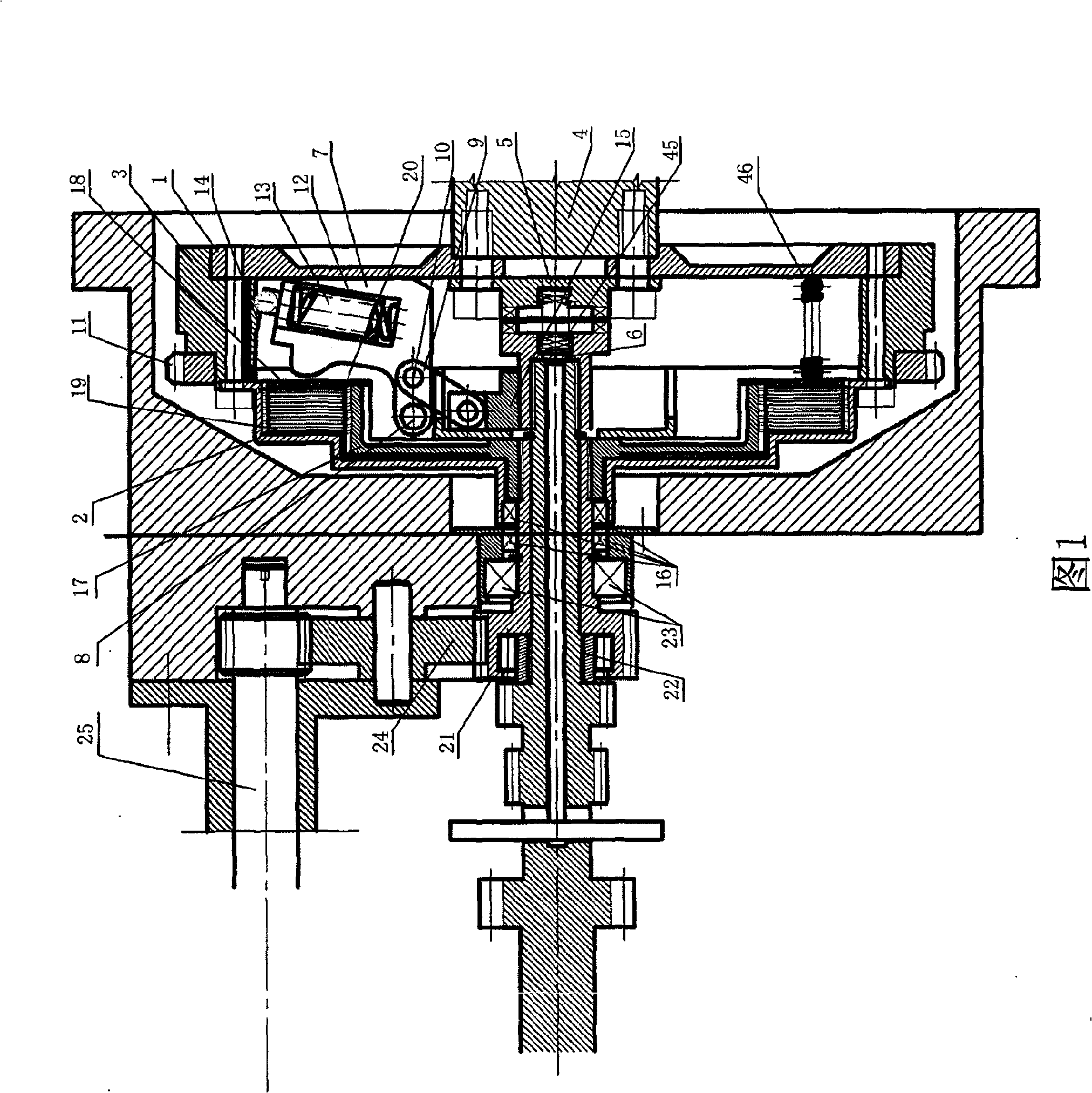

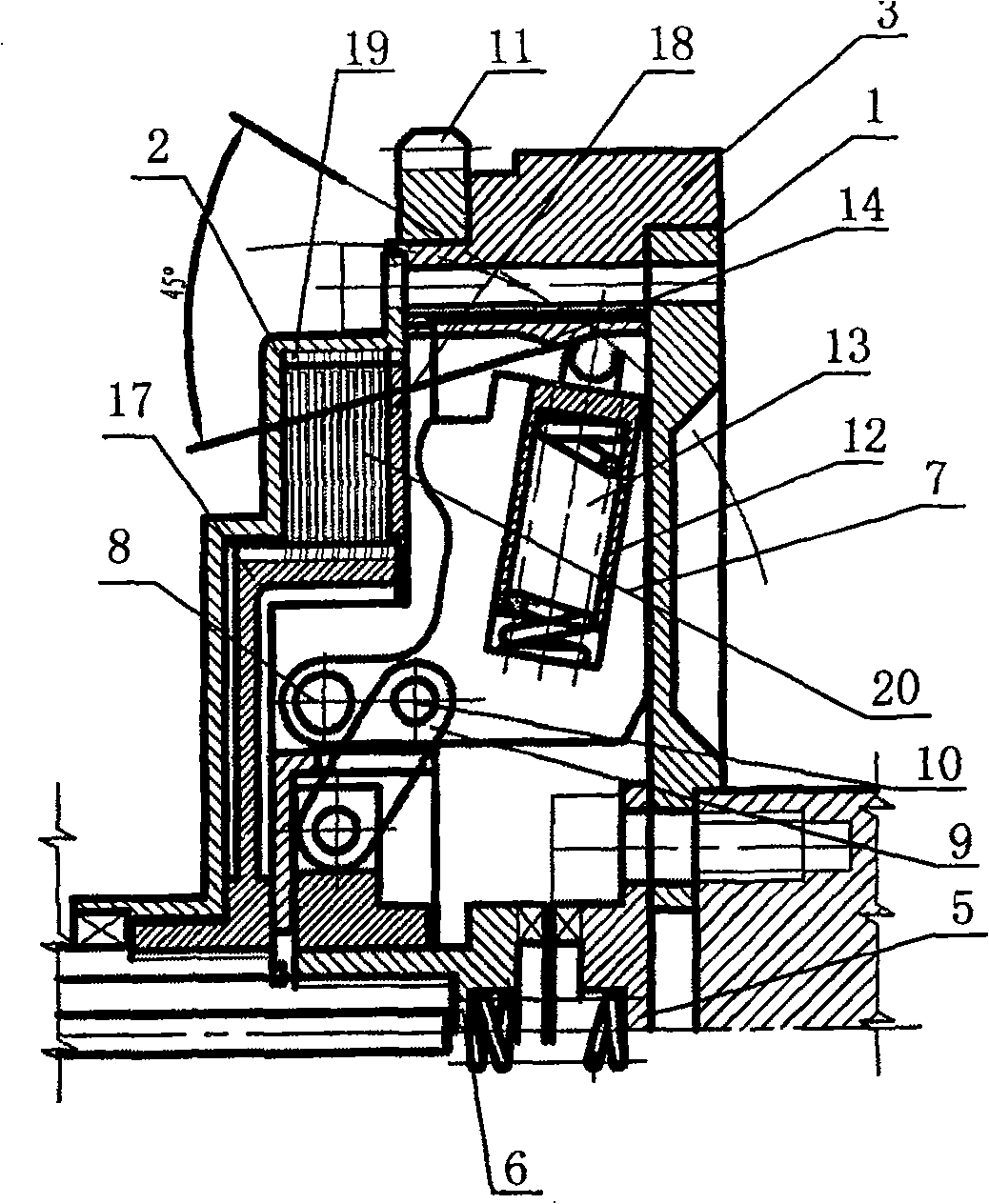

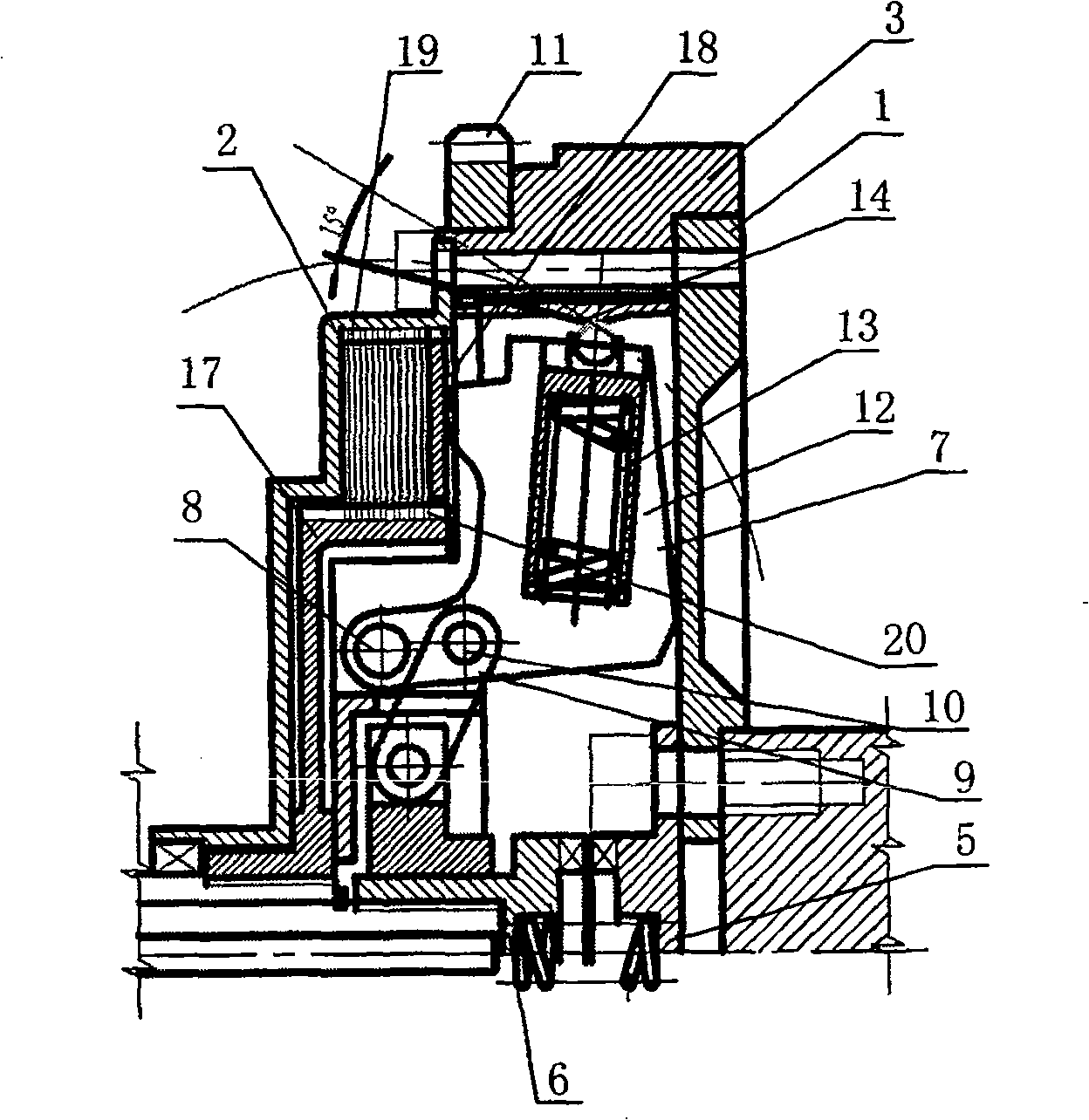

[0034] As shown in Figures 1 to 8, an automatic clutch for a vehicle includes a front disc, a rear disc and a middle disc. The front disc is a circular metal disc, and the right end of the center part of the front disc is coaxially fixed with the output shaft of the engine. The left end of the central part is coaxially connected to a fixed gear pair of an end-face toothed locker. The movable gear pair is coupled with the fixed gear pair. The movable gear pair is installed on the input shaft of the gearbox in a splined manner. The fixed gear pair A separation spring between the pair and the movable tooth pair keeps the locker in a constant state; the middle plate is a circular metal plate, and the left end of the outer circle is coaxially fixed with the rear plate; the rear plate is a circular metal plate Disk, the outer circle of the rear disk is fixedly connected with the central disk, the center of the left end of the central disk is wall-shaped, forming a cavity with the wal...

Embodiment 2

[0050] An automatic clutch for a vehicle, comprising a front disc, a rear disc and a middle disc, the front disc is a circular metal disc, the right end of the central part of the front disc is coaxially connected with the output shaft of the engine, and the left end of the central part is coaxially connected to the A fixed gear pair of an end-toothed locking device is coupled with a movable gear pair. The movable gear pair is installed on the input shaft of the gearbox in a spline manner. Only the separation spring keeps the locker in a normal state; the middle plate is a circular metal plate, the right end of the outer circle of the middle plate is coaxially fixed with the front plate, and the left end of the outer circle is coaxially fixed with the rear plate; the rear plate It is a circular metal plate, and the right end of the outer circle of the rear plate is fixedly connected with the middle plate. The center part of the left end of the middle plate is wall-shaped, formi...

Embodiment 3

[0066] An automatic clutch for a vehicle, comprising a front disc, a rear disc and a middle disc, the front disc is a circular metal disc, the right end of the central part of the front disc is coaxially connected with the output shaft of the engine, and the left end of the central part is coaxially connected to the A fixed gear pair of an end-toothed locking device is coupled with a movable gear pair. The movable gear pair is installed on the input shaft of the gearbox in a spline manner. Only the separation spring keeps the locker in a normal state; the middle plate is a circular metal plate, the right end of the outer circle of the middle plate is coaxially fixed with the front plate, and the left end of the outer circle is coaxially fixed with the rear plate; the rear plate It is a circular metal plate, and the right end of the outer circle of the rear plate is fixedly connected with the middle plate. The center part of the left end of the middle plate is wall-shaped, formi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com