Chemical pulse compound unplugging method

A pulse and chemical technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of many times of drawing pipe string, complicated construction, unsatisfactory plugging effect, etc., and achieve simple construction and shorten construction Cycle, improve the effect of plugging removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

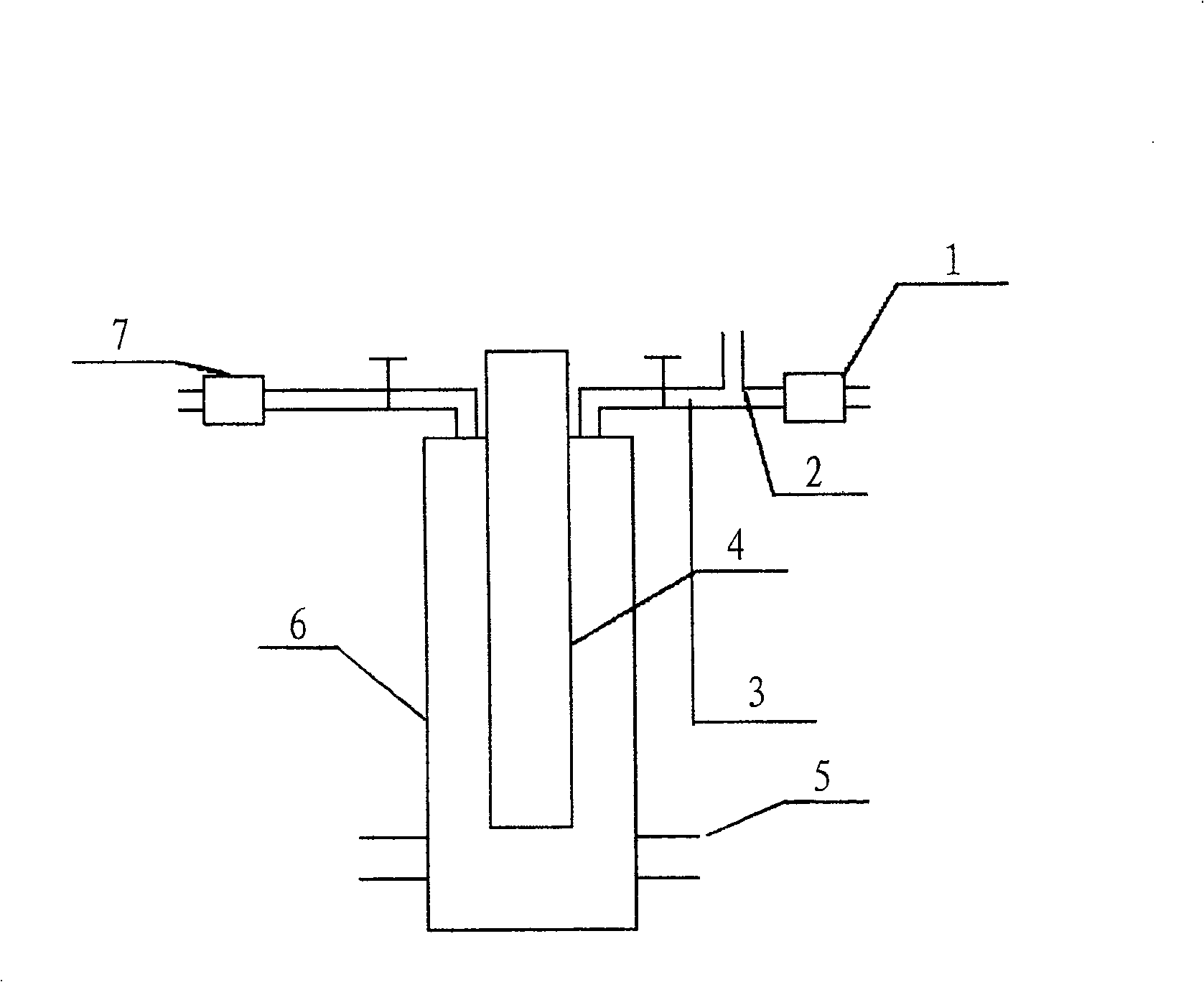

[0020] Example 1: Well GD1-7-411, the thickness of the reservoir is 5.1m, and the average daily fluid production in August 2006 is 5.5m 3 Analyzed that during the production process, mud migration caused blockage of the sand control string and pollution in the near-well area. The design uses pressure pulses to fluctuate the oil layer, and compound acidification and plugging agent to remove the pollutants and blockages in the near-well area. Objects, dredge the strata.

[0021] The well was constructed on August 29, 2006. The production pipe 4 was not moved, and 5m was injected from the tee 2 injection pipe 3 with a 400 cement truck. 3 Acidify the plugging release agent and inject the oil layer 5 from the casing 6. The original solution is 0.8t, the use concentration is 20% after preparation, the processing radius is 1m, the injection pump pressure is stable and less than 12Mpa, and the well is shut in for 2-3 hours. Connect the tee 2 and the pressure pulse generator 1 to the outsi...

example 2

[0023] Example 2: Well GD2-28X239, the thickness of the oil layer is 6.8m, and the average daily fluid production in September 2006 is 5.1m 3 According to analysis, it is believed that the thick oil in the production process causes blockage in the near-well area. The design uses pressure pulses to fluctuate and impact the oil layer, and compound viscosity reducers to remove the heavy oil blockage in the near-well area and dredge the formation.

[0024] The well was constructed on September 7, 2006. The oil production string was not moved, and 6m was injected with a 400 cement truck. 3 The thick oil viscosity reducer stock solution is 0.6t, the use concentration is 10% after preparation, the processing radius is 1m, the injection pump pressure is stable and less than 12Mpa, and the well is shut in for 2-3 hours. Connect the tee and pressure pulse generator to the outside of the casing gate, connect the power supply of the pulse generator control device, and place the pressure pulse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com