Stator, motor, and method of manufacturing such stator

A stator and rotor technology, which is used in the manufacture of stator/rotor bodies, motor generators, and prefabricated windings embedded in motors. issues such as

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

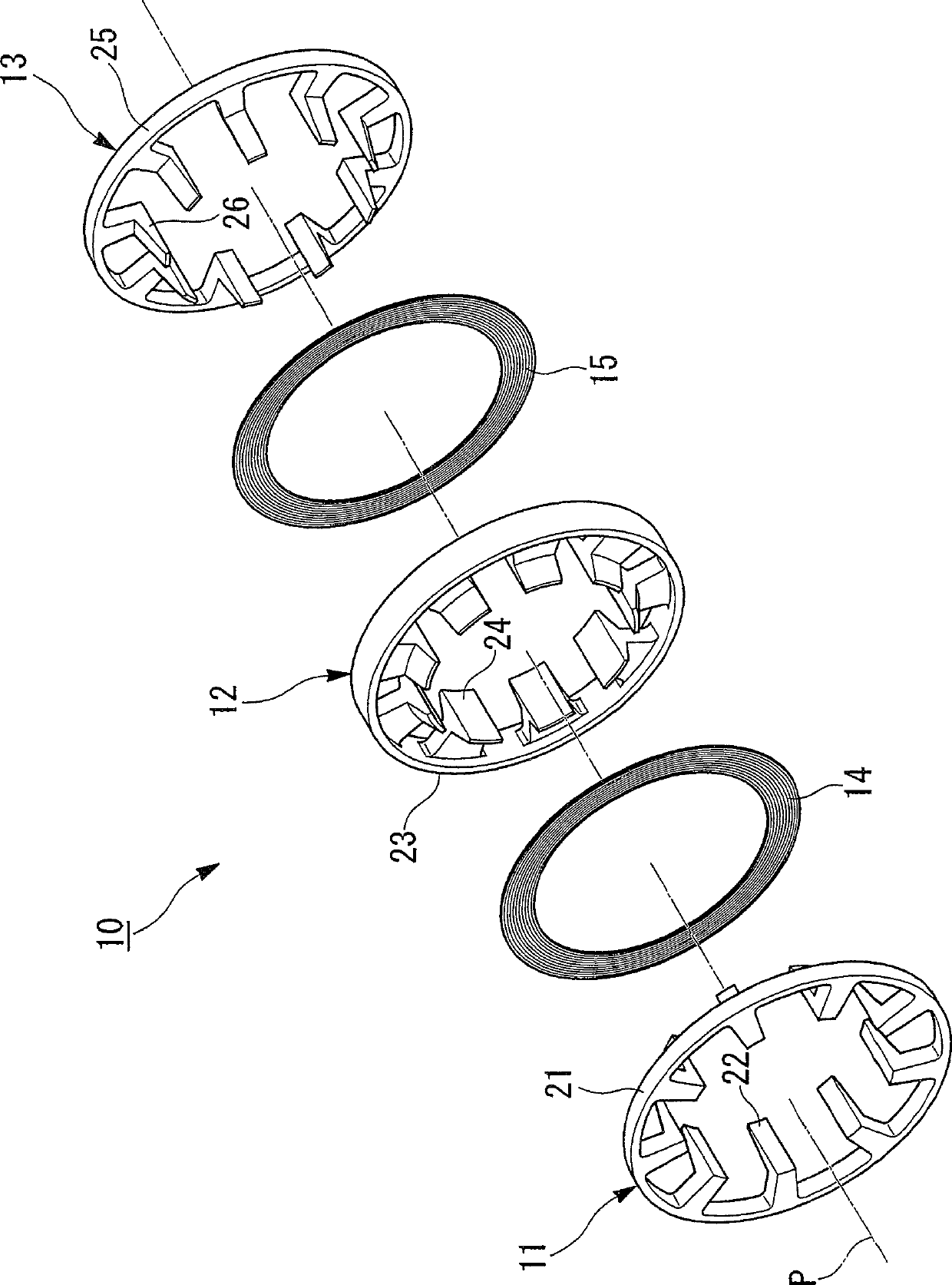

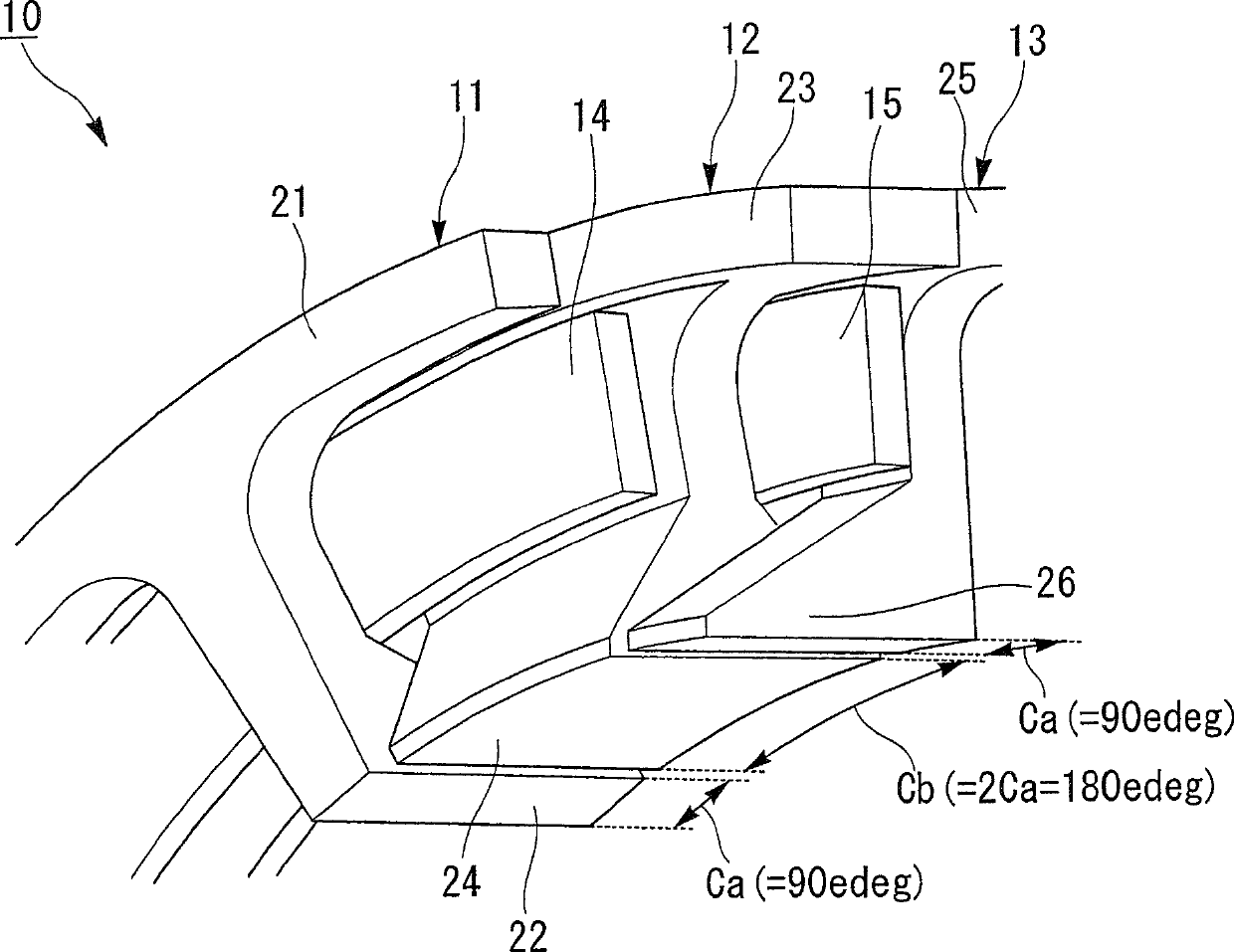

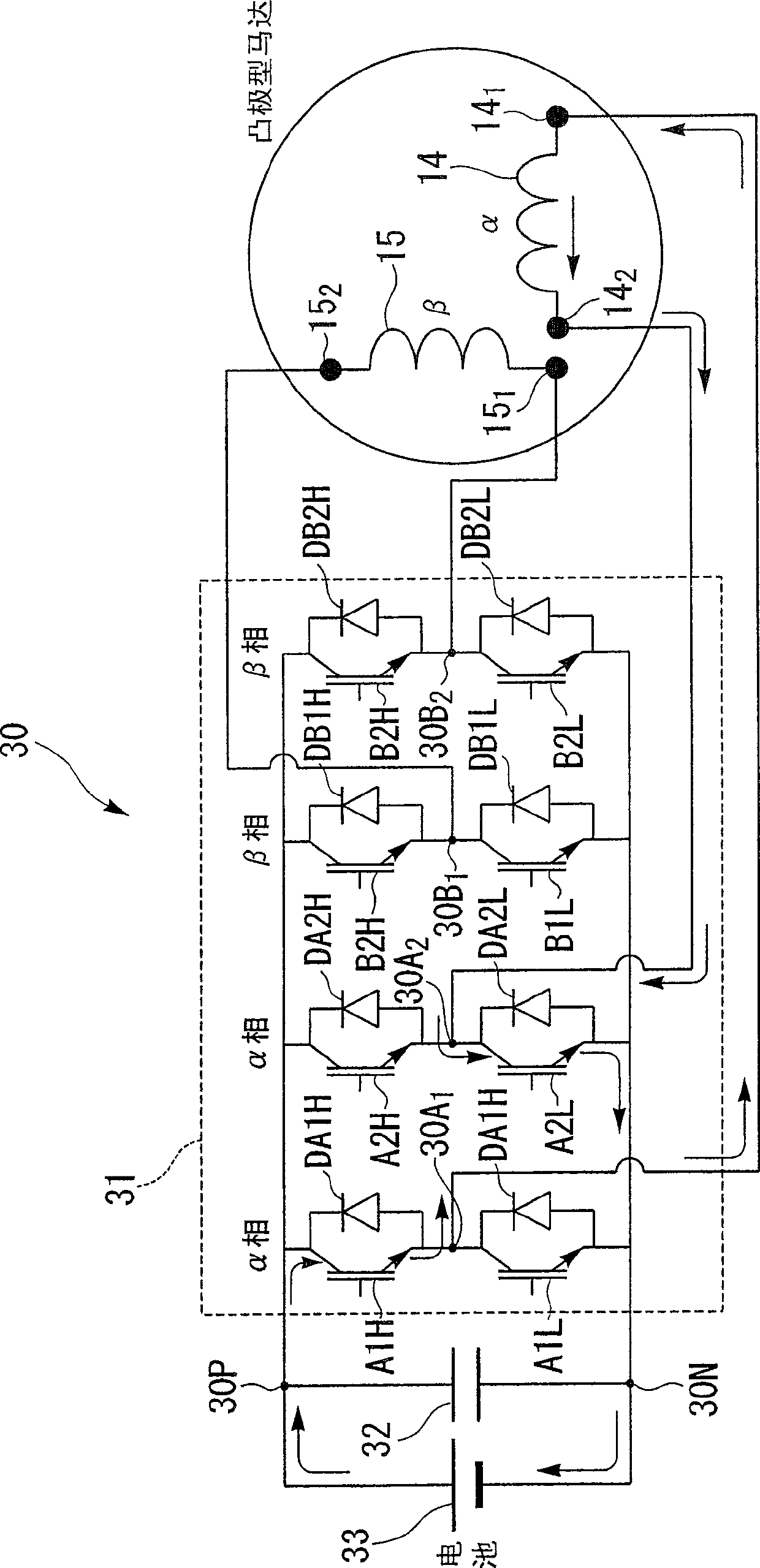

[0198] Hereinafter, a first embodiment of the stator of the present invention will be described with reference to the drawings.

[0199] The stator 10 of this embodiment constitutes, for example, a salient-pole motor mounted on a hybrid vehicle as a drive source of the vehicle together with an internal combustion engine, and is configured, for example, in a structure in which the internal combustion engine, the salient-pole motor, and a transmission are directly connected in series. In a parallel hybrid vehicle, at least the driving force of either the internal combustion engine or the salient-pole motor is transmitted to the drive wheels of the vehicle through a transmission.

[0200] Also, when the driving force is transmitted from the driving wheel side to the salient pole motor when the vehicle decelerates, the salient pole motor functions as a generator to generate so-called regenerative braking force, and recovers the kinetic energy of the vehicle body as electric energy ...

no. 2 approach

[0232] Hereinafter, a second embodiment of the stator of the present invention will be described with reference to the drawings.

[0233] As in Embodiment 1, the stator 110 of this embodiment constitutes, for example, a salient-pole motor mounted on a hybrid vehicle as a driving source of the vehicle together with an internal combustion engine. For example, the internal combustion engine, the salient-pole motor, and the transmission In a parallel hybrid vehicle having a structure in which the devices are directly coupled, at least the driving force of either the internal combustion engine or the salient pole motor is transmitted to the driving wheels of the vehicle through the transmission.

[0234] When the driving force is transmitted from the drive wheel side to the salient pole motor when the vehicle decelerates, the salient pole motor functions as a generator to generate so-called regenerative braking force, and recovers the kinetic energy of the vehicle body as electric e...

no. 3 approach

[0310] Hereinafter, a third embodiment of the stator of the present invention will be described with reference to the drawings.

[0311] The stator 50 of the third embodiment differs from the stator 110 of the above-mentioned second embodiment in that the U-phase loop winding 54 and the W-phase loop winding 55 do not have the respective U-phase meandering parts 131 and W-phase meandering parts 131 . Section 132 of this.

[0312] Hereinafter, the description of the same parts as those of the second embodiment will be simplified or omitted.

[0313] For example Figure 24 and Figure 25 As shown, the stator 50 of this embodiment includes: a U-phase stator ring 51, a V-phase stator ring 52, a W-phase stator ring 53, and a U-phase stator ring 53 for each of the three phases composed of a U-phase, a V-phase, and a W-phase. Two-phase U-phase toroidal winding 54 and W-phase toroidal winding 55 constituted by a phase and a W-phase.

[0314] The U-phase stator ring 51 has a substan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com