honeycomb structure spherical LiFePO4 / C composite material preparation method

A composite material, honeycomb structure technology, applied in structural parts, chemical instruments and methods, electrode manufacturing, etc., can solve problems such as safety, problems, and restrictions on the application of lithium-ion batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

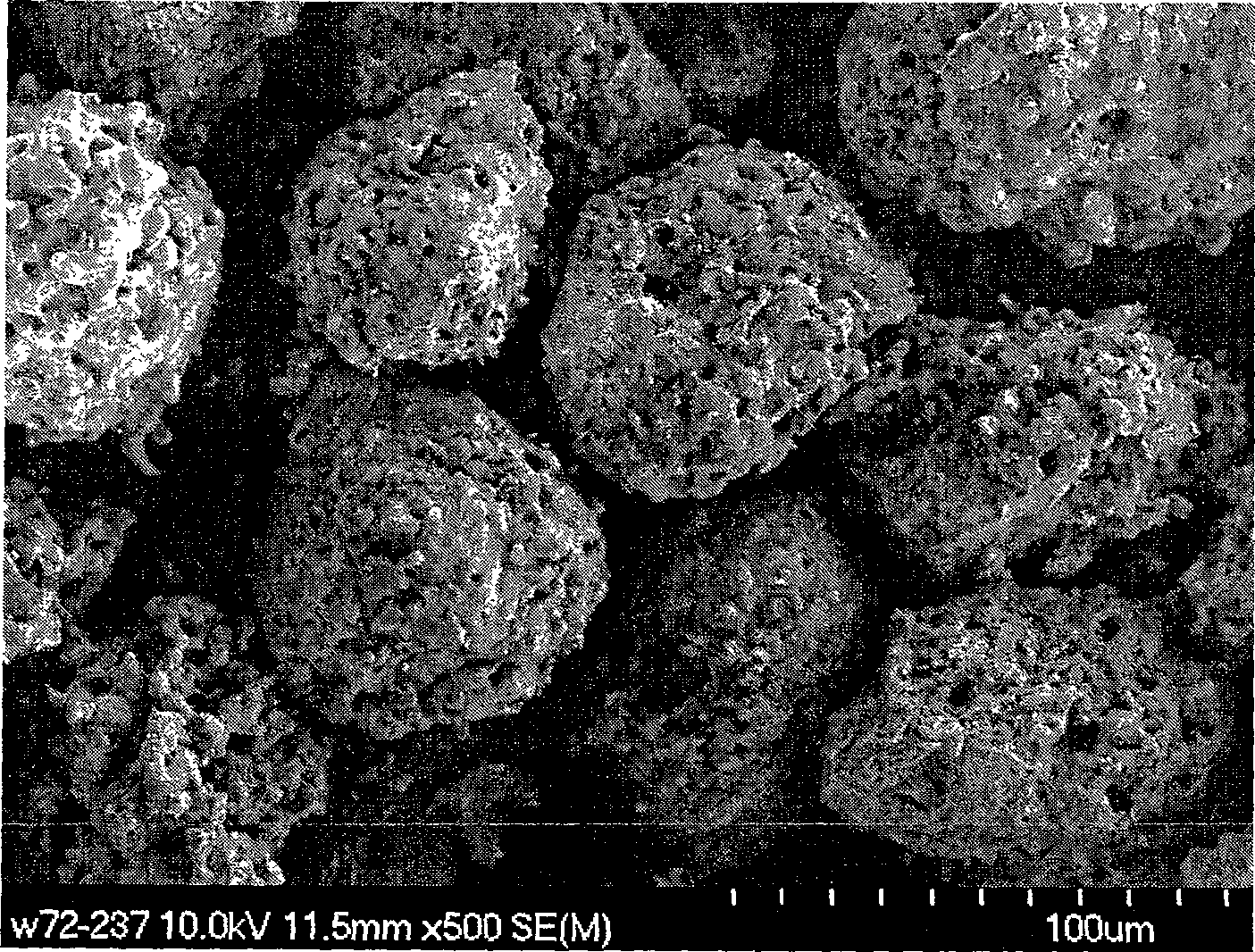

specific Embodiment approach 1

[0007] Specific implementation mode 1: In this implementation mode, the honeycomb structure spherical LiFePO 4 / C Composites by NH 4 FePO 4 ·H 2 O. Li 2 CO 3 and glucose, where NH 4 FePO 4 ·H 2 O and Li 2 CO 3 The molar ratio of C and LiFePO in glucose is 2:1 4 The mass ratio is 1:10~30; said NH 4 FePO 4 ·H 2 O is made from ferrous sulfate, phosphoric acid and ammonia water at a molar ratio of 1:1~1.5:1~1.2.

specific Embodiment approach 2

[0008] Embodiment 2: In this embodiment, the molar ratio of ferrous sulfate, phosphoric acid and ammonia water is 1:1-1.3:1-1.1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific Embodiment Three: In this embodiment, the molar ratio of ferrous sulfate, phosphoric acid and ammonia water is 1:1.2:1.05. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com