Process of making ring fine crystal blank of GH4169 alloy for near constant temperature forging

A GH4169, isothermal forging technology, applied in the field of blank making of deformed superalloy forging blanks, can solve the problems of high cost of consolidated powder blanks, many technical problems, unstable quality of forgings, etc. Cost, Ease of Access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] To implement the method for making a fine-grained ring billet for near-isothermal forging of GH4169 alloy according to the present invention, it is necessary to provide a forging heating furnace, a forging press, a rolling mill and a cast, forged or rolled GH4169 alloy original rod.

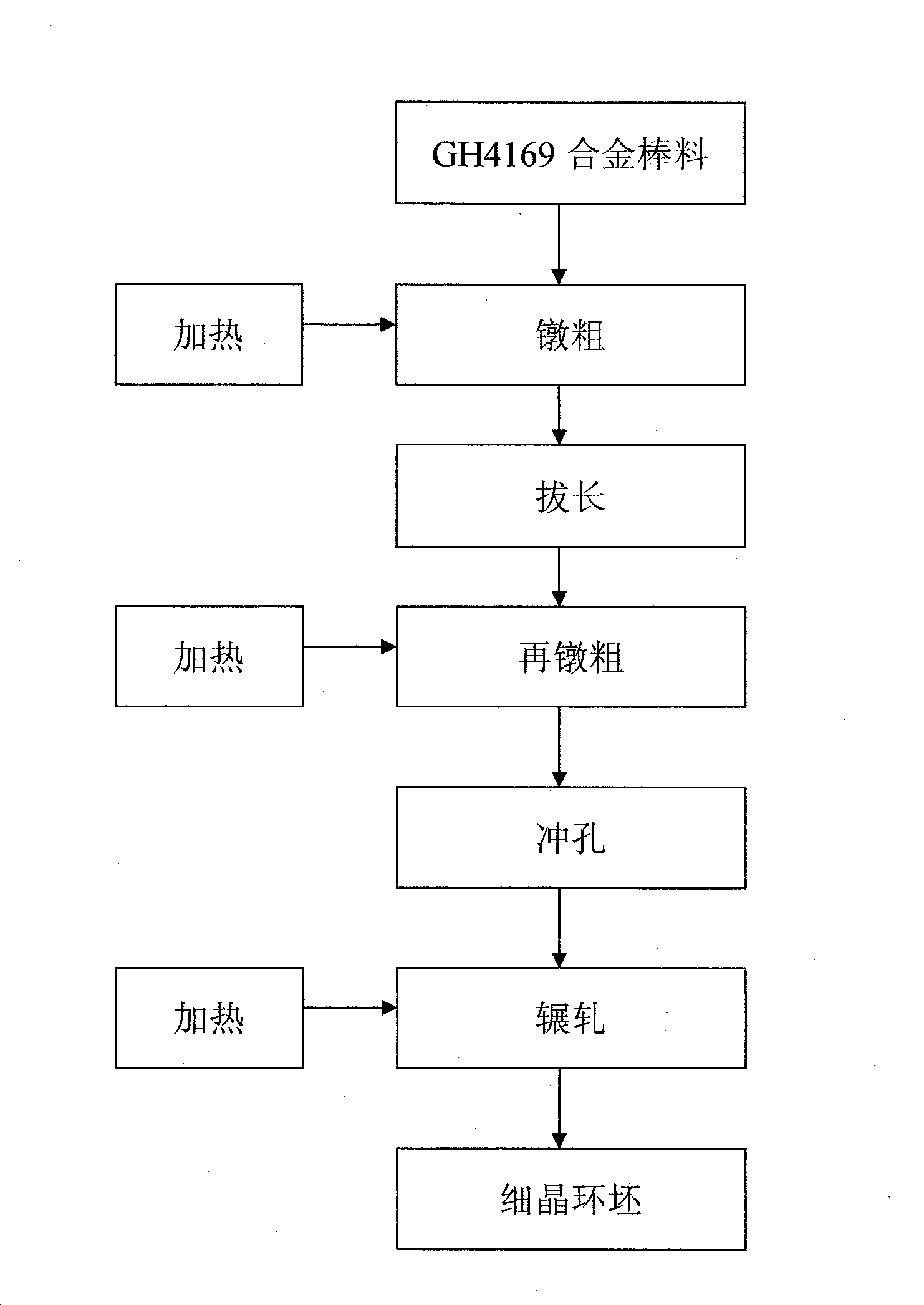

[0019] figure 1 Shown is the technological process of the billet making method of the fine-grained ring blank for near-isothermal forging of GH4169 alloy, and the operation steps of the billet making method are as follows:

[0020] Step 1: Upsetting. Heat the GH4169 alloy rods blanked according to the forging specifications to 980 ° C ~ 1010 ° C in the heating furnace, preferably at a temperature of 1010 ° C, and then upset the bars to 1 / 3 ~ 1 / 3 of the height of the original bars on the forging press 1 / 2 height to get a cake base.

[0021] Step 2: Pull out the length. The primary cake blank described in step 1 is drawn on a forging press to return to the height of the original bar to ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com