Automatic adding and discharging carrier of sclerometer and measuring cell

A technology of measuring unit and hardness tester, applied in the direction of testing material hardness, etc., can solve the problems of actual depth measurement error, low precision, large volume, etc., and achieve the effect of no conversion deviation, high precision, and high repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

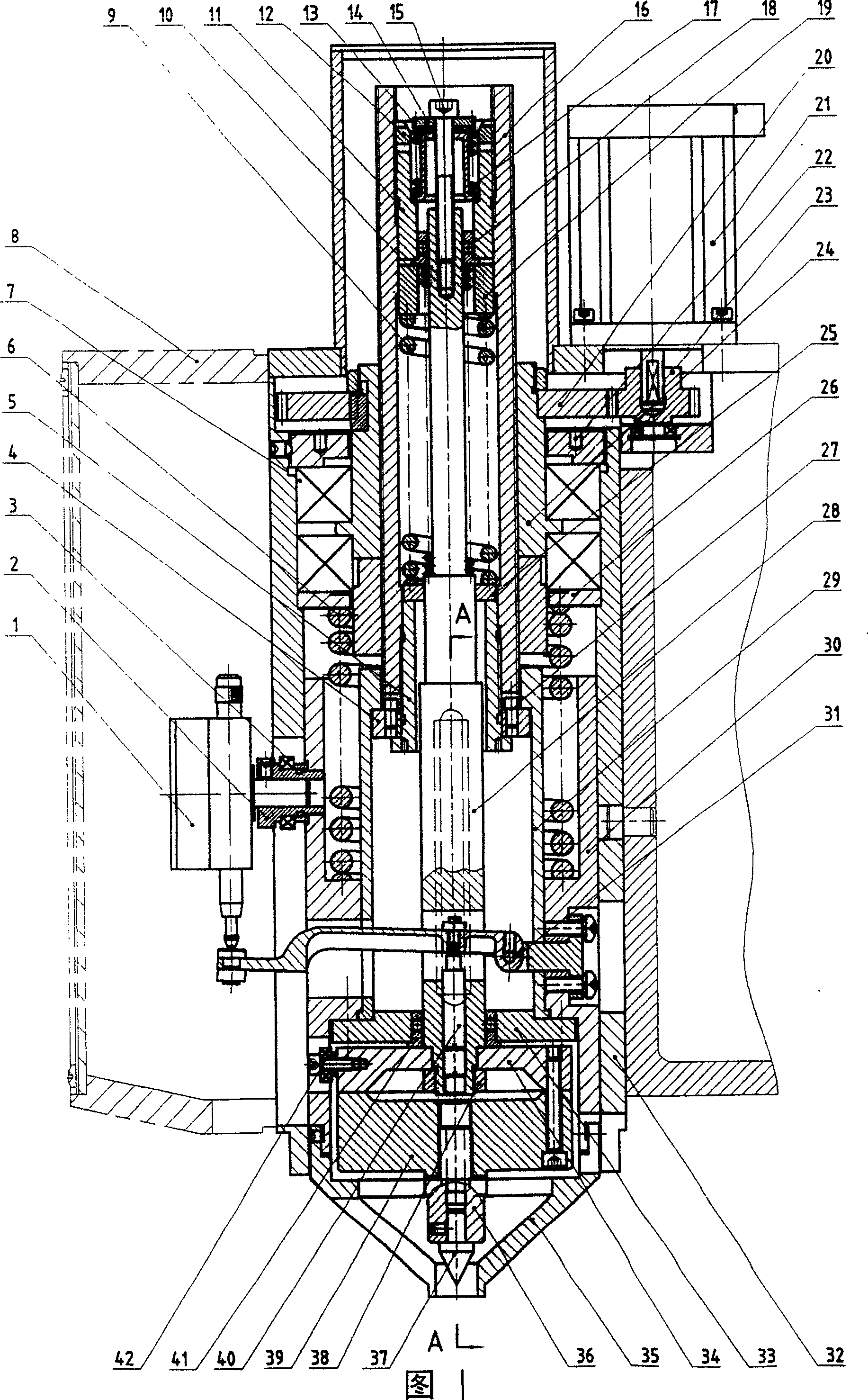

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] Design concept of the present invention is:

[0030] (1) In order to facilitate the connection with the frame, a supporting frame with an outer square and an inner circle is adopted.

[0031] (2) Stepping drive mechanism, high-precision pressure sensor and electric control system are adopted, and the gear transmission mechanism is driven by the stepping motor, thereby driving the ball screw to clamp the test piece, apply and remove the test force. Another function of the stepping drive mechanism to drive the ball screw is to realize the up and down movement of the indenter to adapt to the different heights of the test pieces.

[0032] (3) The test force spring is compressed by the ball screw, and the test force is transmitted to the spindle indenter through the test force spring; the application of the test force is realized i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com