Method for synthesizing controllable template of nano polyaniline tube

A synthesis method and nanotube technology, which is applied in the field of controllable synthesis of new conjugated polymer nanotubes, can solve the problems of uncontrolled synthesis of polyaniline nanotubes and low residual amount, so as to ensure product quality and simplify experiments The effect of steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

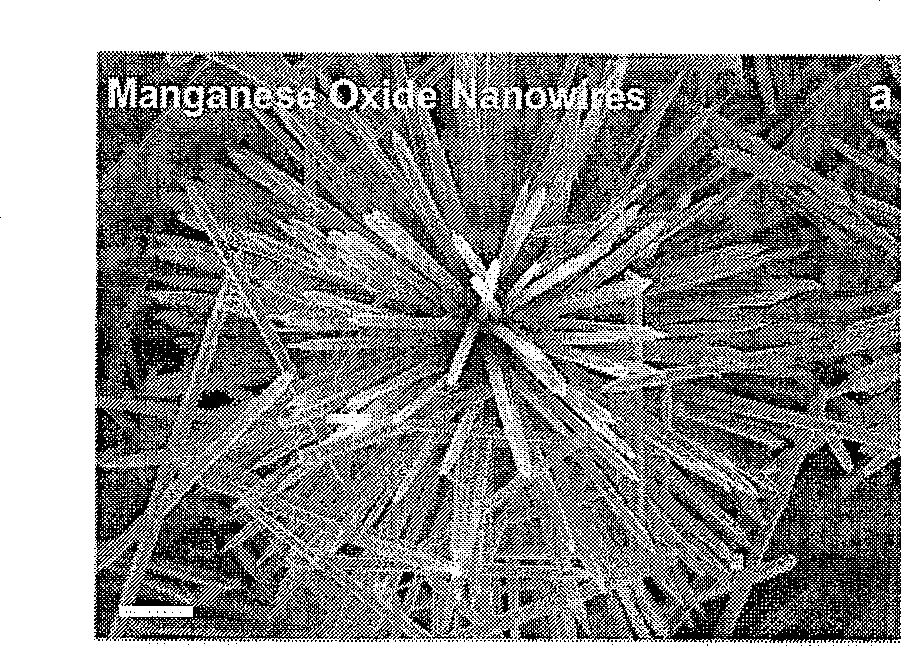

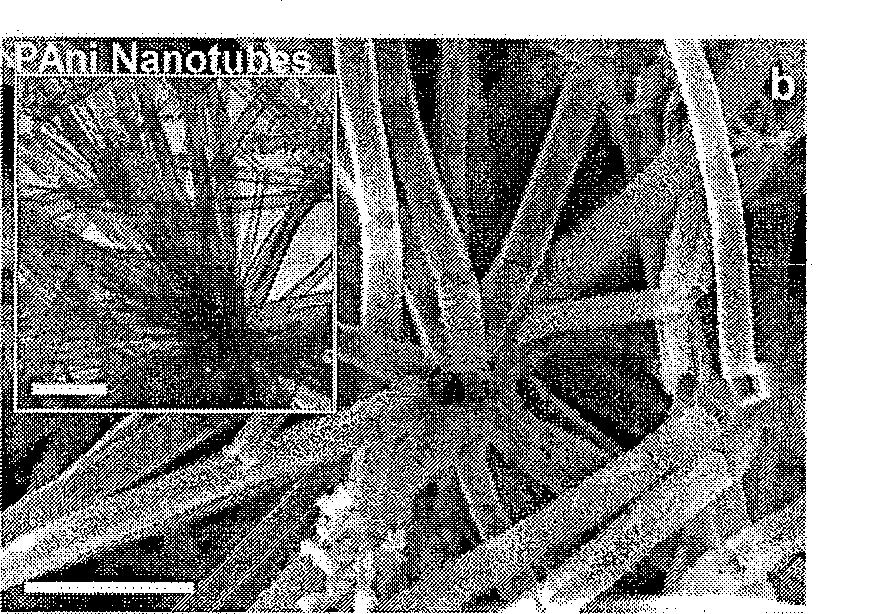

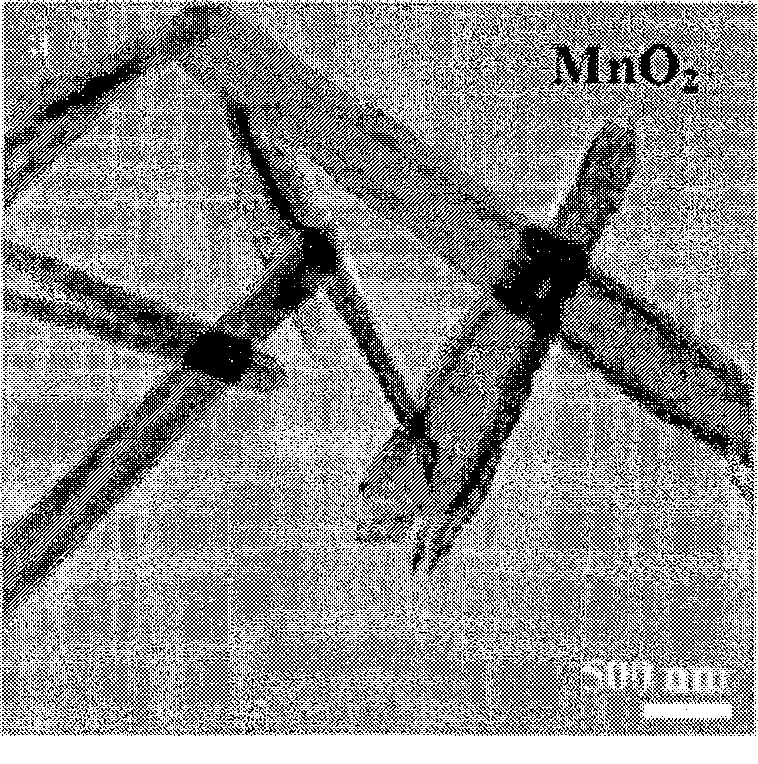

[0016] Using MnO 2 A typical method for template synthesis of polyaniline nanotubes is as follows: 2 nanofibers or β-MnO 2 The nanotubes were ultrasonically dispersed in 30ml of deionized water, and then placed in an ice-water bath environment and kept stirring slowly; at the same time, we diluted 2.8ml of concentrated sulfuric acid at a ratio of 1:6.15, and after cooling to room temperature, slowly added 96 μl of aniline monomer, and stir well, and finally this solution is quickly transferred into the dispersed MnO 2 Template in 30ml of aqueous solution, and after reacting for 6 hours in an ice-water bath and stirring environment, a dark green solid product was obtained. After the product is filtered through a microporous filter paper (Millipore, type GN, 0.20 μm filter), it is washed repeatedly with deionized water and ethanol to remove residual ions and oligomers on the surface, and the final product will be dried under vacuum at 60°C (12 hours).

[0017] The reaction s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com