Battery pack

A technology for battery packs and batteries, which is applied in the direction of battery pack parts, circuits, electrical components, etc., can solve the problems of reducing connection impedance, enlarging the shape of the shell, and large connection resistance, so as to achieve high production efficiency and reliability, shorten Connection path, effect of reducing connection resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

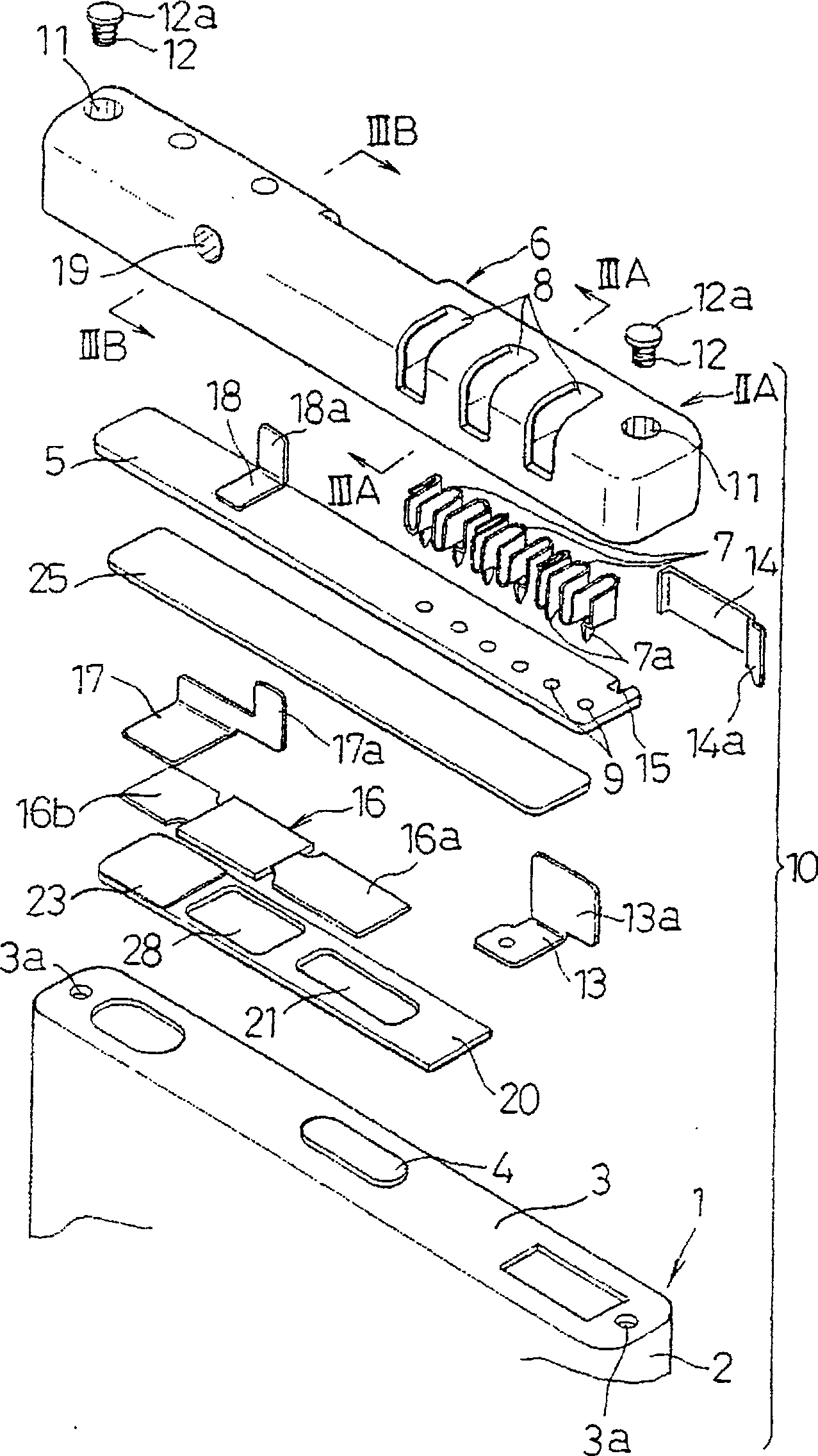

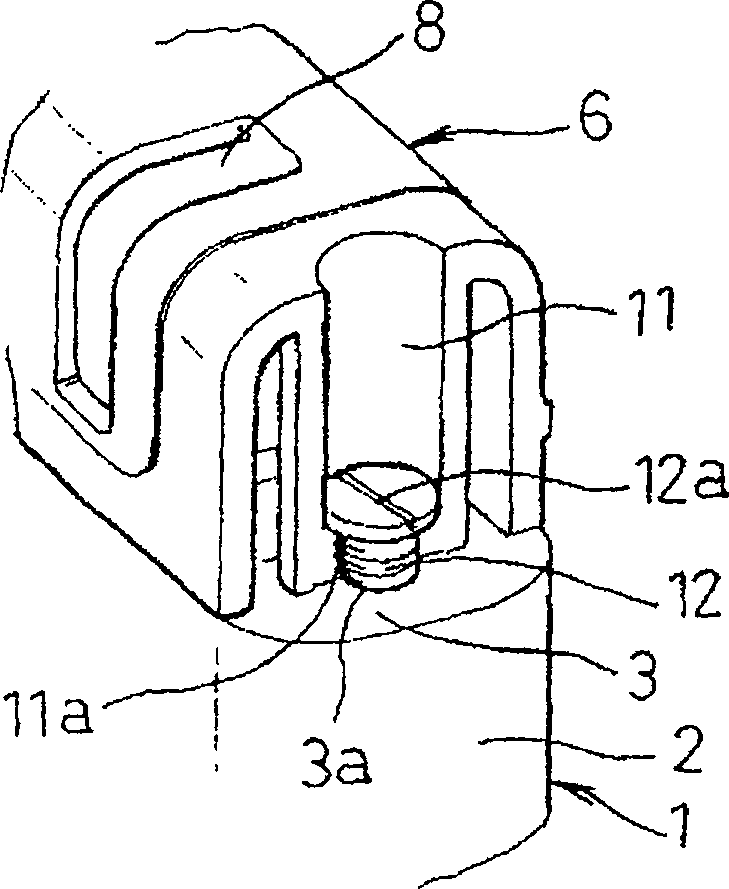

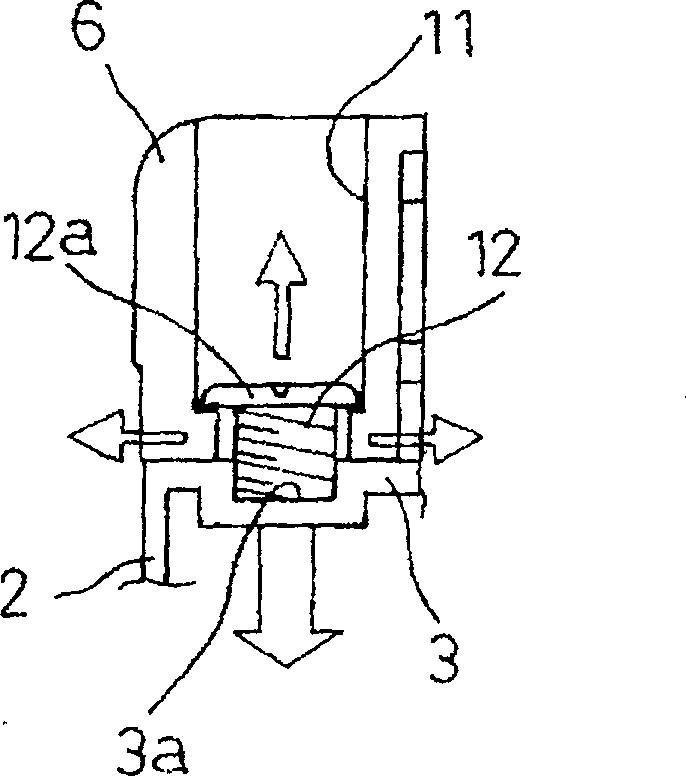

Embodiment 1

[0048] figure 1 Among them, 1 is a battery whose cross-sectional shape is a flat rectangle or a rectangular or elliptical square corner with an arc-shaped inner corner. The battery 1 is composed of a lithium-ion battery. liquid. The structure of the electrode plate group is a structure in which strip-shaped positive electrode plates and negative electrode plates are wound into a roll with a separator interposed between them, and stacked in multiple layers. The positive electrode plate is coated with a positive electrode mixture (positive electrode mixture) on the core material composed of aluminum foil compound) and then dried, the negative electrode plate adopts a structure in which the negative electrode mixture is coated on the core material made of copper foil and then dried, and the separator is made of a microporous polypropylene film or the like.

[0049] An electrode terminal 4 protrudes from the center of the one end surface 3 of the battery case 2 . The electrode...

Embodiment 2

[0070] Next, a second embodiment of the present invention will be described. In addition, the same reference numerals are assigned to the same components as those of the first embodiment described above, their descriptions are omitted, and only the differences will be mainly described.

[0071] The first embodiment describes an example in which the battery case 2 and the end case 6 are fixed together by screwing the top end of the screw 12 into one end face 3 of the battery case 2, while the present embodiment is like Figure 9 ~ Figure 10 As shown, the head 22a of the coupling pin 22 with a head is coupled to the step 11a of the mounting hole 11 at both ends of the end housing 6, and its top end is welded to both ends of the one end surface 3 of the battery case 2. on, thus fixed into one. As the welding method, methods such as spot welding, arc welding, and laser welding can be used, but spot welding which is inexpensive and has good workability is preferable.

[0072] The...

Embodiment 3

[0076] Next, a third embodiment of the battery pack of the present invention will be described. In addition, the same reference numerals are assigned to the same components as those of the above-mentioned second embodiment, and description thereof will be omitted, and only the differences will be mainly described.

[0077] What has been described in the second embodiment is an example in which the top end of the connecting pin 22 is directly resistance-welded to the end face 3 of the battery case 2, but for example, the end face 3 of the battery case 2 is made of aluminum or an aluminum alloy, and the connecting pin 22 In the case of small parts made of iron-based materials such as stainless steel or nickel-plated steel to ensure sufficient strength, it may be difficult to secure the necessary fixing strength and high reliability if they are directly resistance-welded. In order to solve such a problem, the one end surface 3 of the battery case 2 in this embodiment adopts the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com