Suction device and electric dust collector therewith

A technology for suction appliances and vacuum cleaners, applied in the fields of suction appliances and electric vacuum cleaners, can solve the problems of unhygienic usability, poor usability, unhygienic, etc., and achieve the effects of excellent usability, improved tightness, and excellent usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

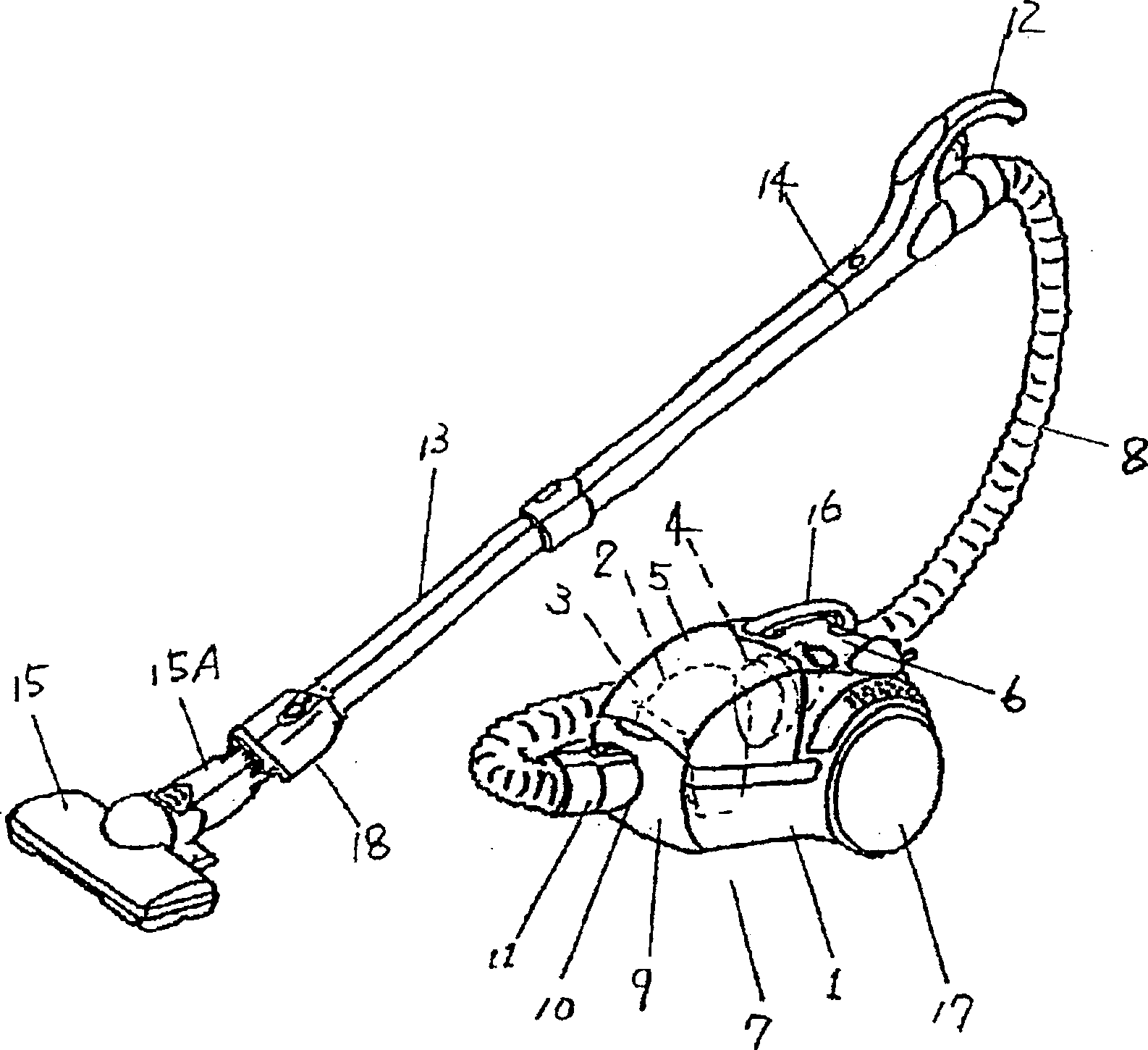

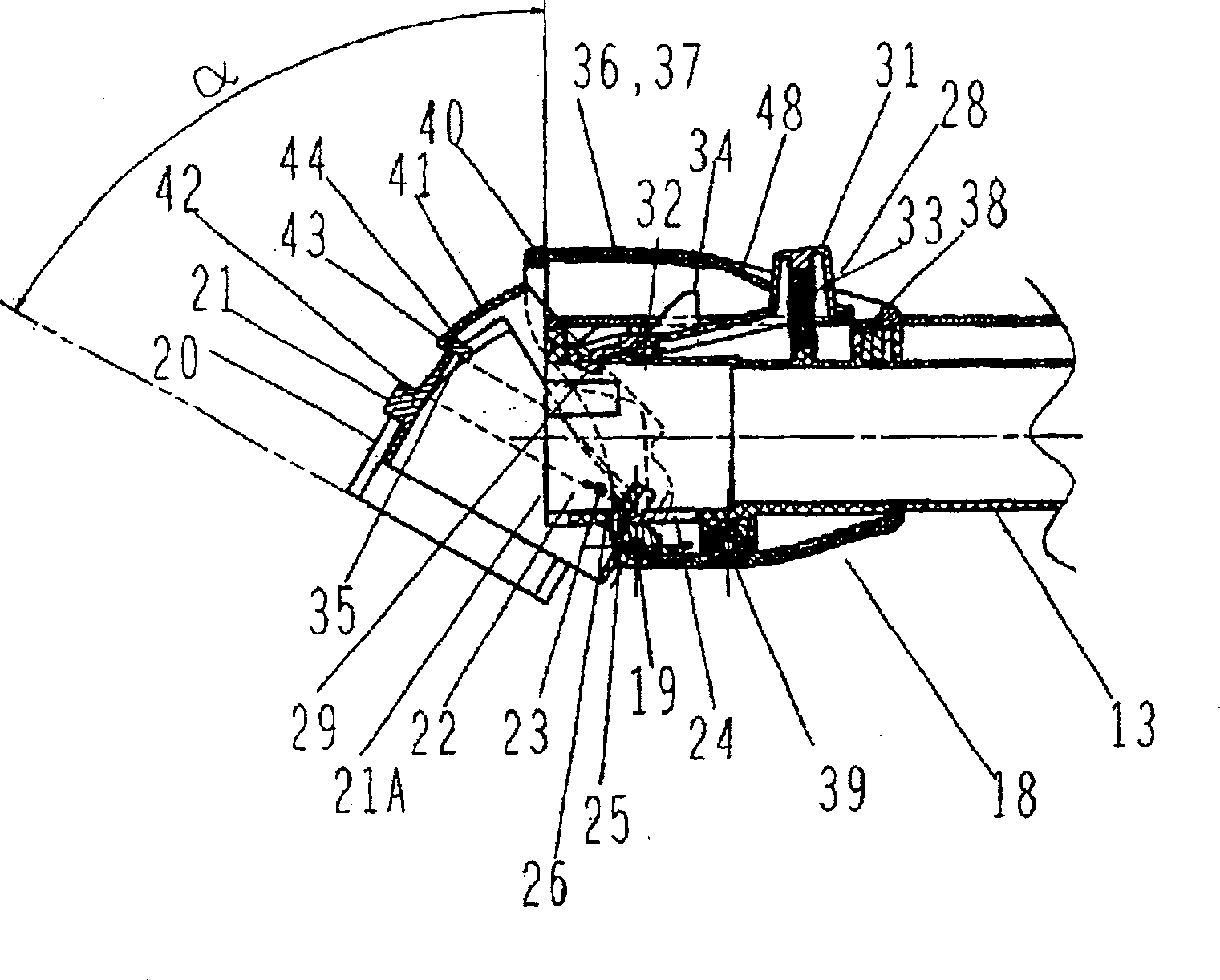

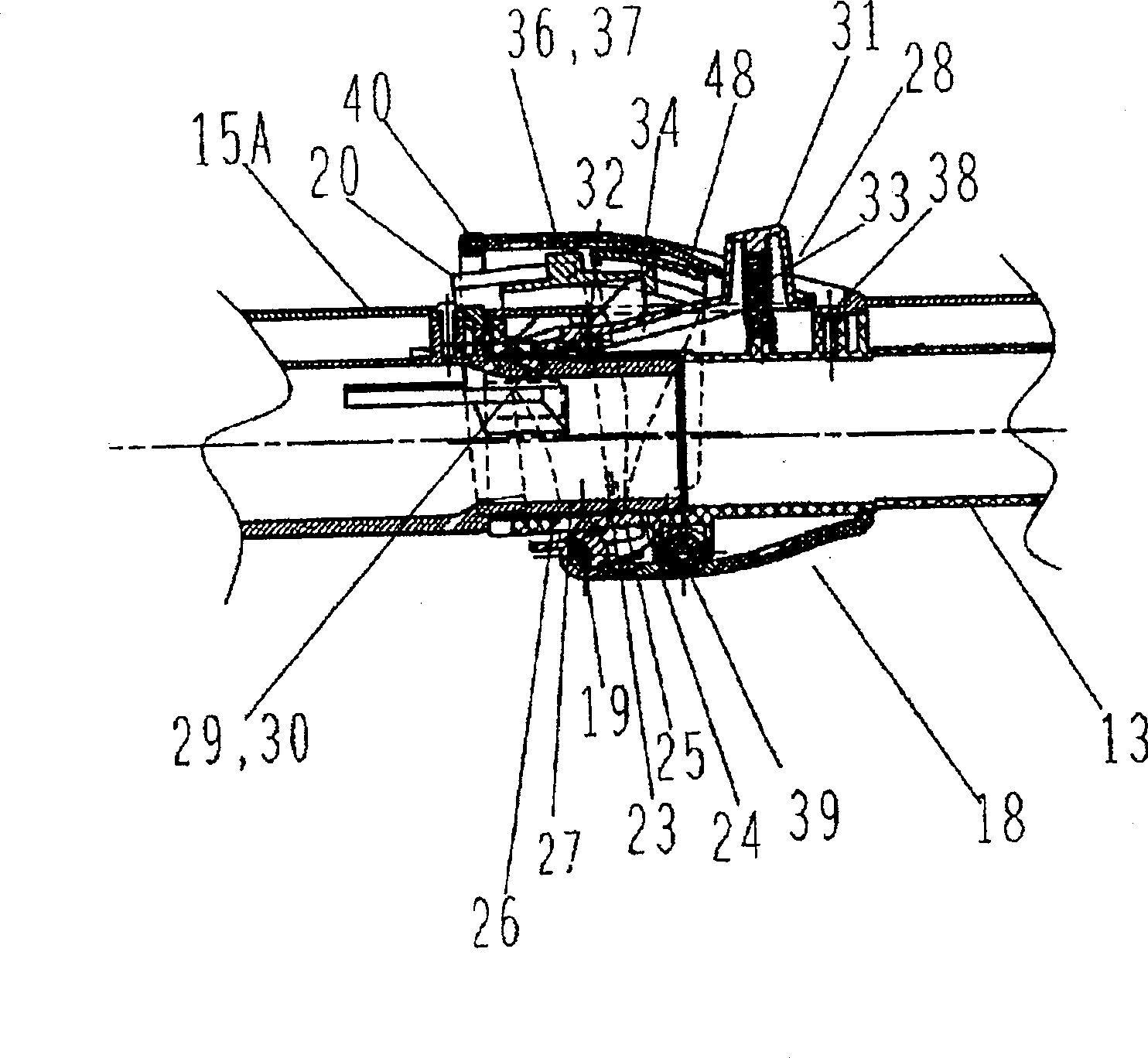

[0045] 1 is the lower part of the main body, which has a dust collection chamber 3 equipped with a dust collection bag 2 for accumulating dust on the front side, and has a dust suction motor 4 at the rear, and forms a collection chamber 5 with a cover 5 covering the dust collection bag 2 at the front. Dust chamber 3, and with main body upper part 6 covering is arranged with the top of rear motor 4 etc., and constitutes electric vacuum cleaner main body (hereinafter referred to as main body) 7. 8 is flexible pipe, and its one end is formed in main body 7 front parts The dust collection chamber 3 communicates, has a connecting duct 11, and forms an operating handle 12 to be held at the other end while in use, and serves as a front end duct 14 having a second connecting pipe connected to the extension pipe 13 as the first connecting pipe. The connecting pipe 11 is connected to the suction port 10 of the suction port 9 of the front cover 9 forming a passage for suction by the attra...

Embodiment approach 2

[0056] use Figure 7 A second embodiment of the present invention will be described.

[0057] In addition, the same code|symbol is attached|subjected to the same member as 1st Embodiment, and the description is abbreviate|omitted.

[0058] Reference numeral 49 serves as an operation pedal provided on the release mechanism operating portion of the suction device pipe 15A of the floor suction device 15 . In addition, 50 is a male terminal, which is connected to a power cord provided with a power source for supplying power to the floor suction device 15 of a drive motor (not shown) that drives a rotating brush (not shown). .

[0059] The above structure works as follows.

[0060] From the state where the floor suction device 15 is used by connecting the suction device pipe 15A to the front end of the extension pipe 13 , when using the suction device 18 , the operation pedal 49 can be pedaled and used as the suction device 18 directly. That is to say, through the engaged part ...

no. 3 approach

[0063] In addition, the same code|symbol is attached|subjected to the same aspect as 1st, 2nd embodiment, and description is abbreviate|omitted.

[0064] Reference numeral 51 denotes an operation lever, which is provided near the handle 12 of the front end 14 as a release mechanism operation unit linked to a release mechanism for releasing the connection between the floor suction device 15 and the extension pipe 13 .

[0065] The above structure works as follows.

[0066] From the state where the floor suction device 15 is used by connecting the suction device pipe 15A to the front end of the extension pipe 13, when using the suction device 18, the operation lever 51 can be operated with the fingers holding the handle, and can be directly used as the suction device 18. That is to say, through the engaged part A34 of the brush holder 21 of the inhalation tool 18 and the engaging part 35 of the clip 28 are disengaged, the brush holder 21 above the extension pipe 13 is pressed by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com