All-solid high-frequency inducing heater

A high-frequency induction heating and induction heater technology, used in induction heating, induction heating control, instrument cooling, etc., to achieve the effect of long life of the whole machine, low self-loss, and arbitrary selection of heating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

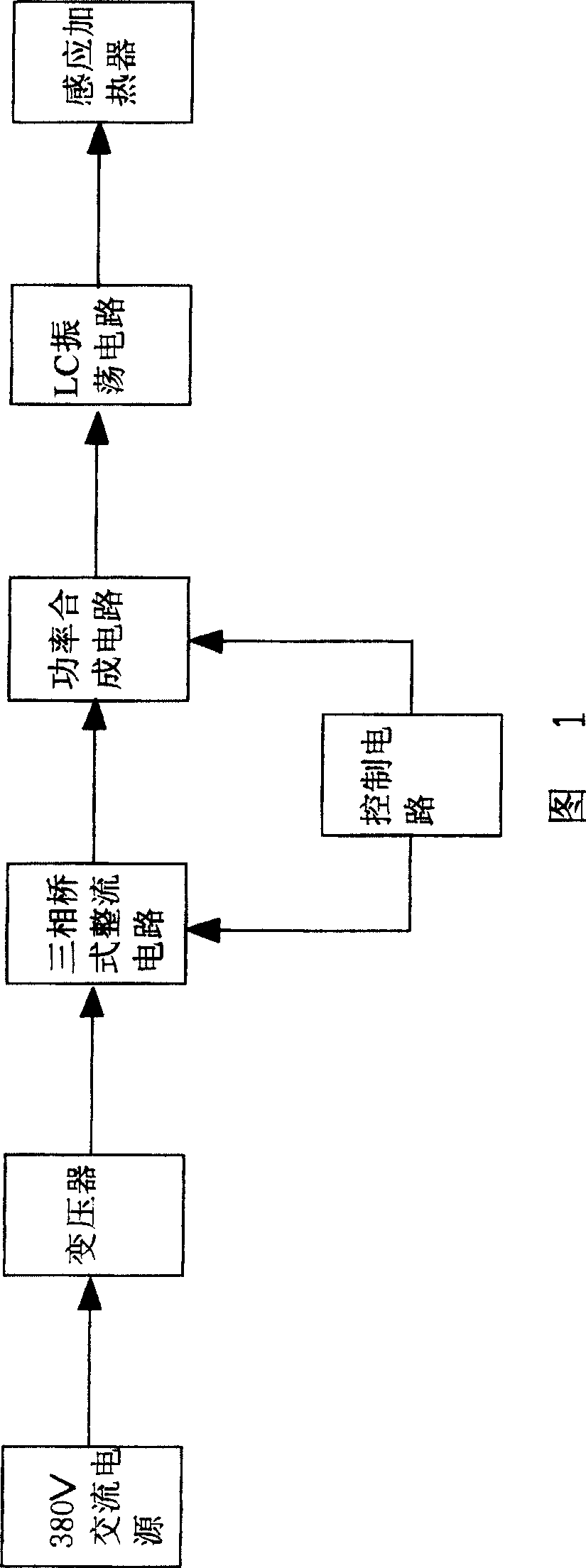

[0012] As shown in Figure 1, the present invention includes a 380V AC power supply, a transformer, a three-phase bridge rectifier circuit, a control circuit, a power synthesis circuit, an LC oscillation circuit, and an induction heater.

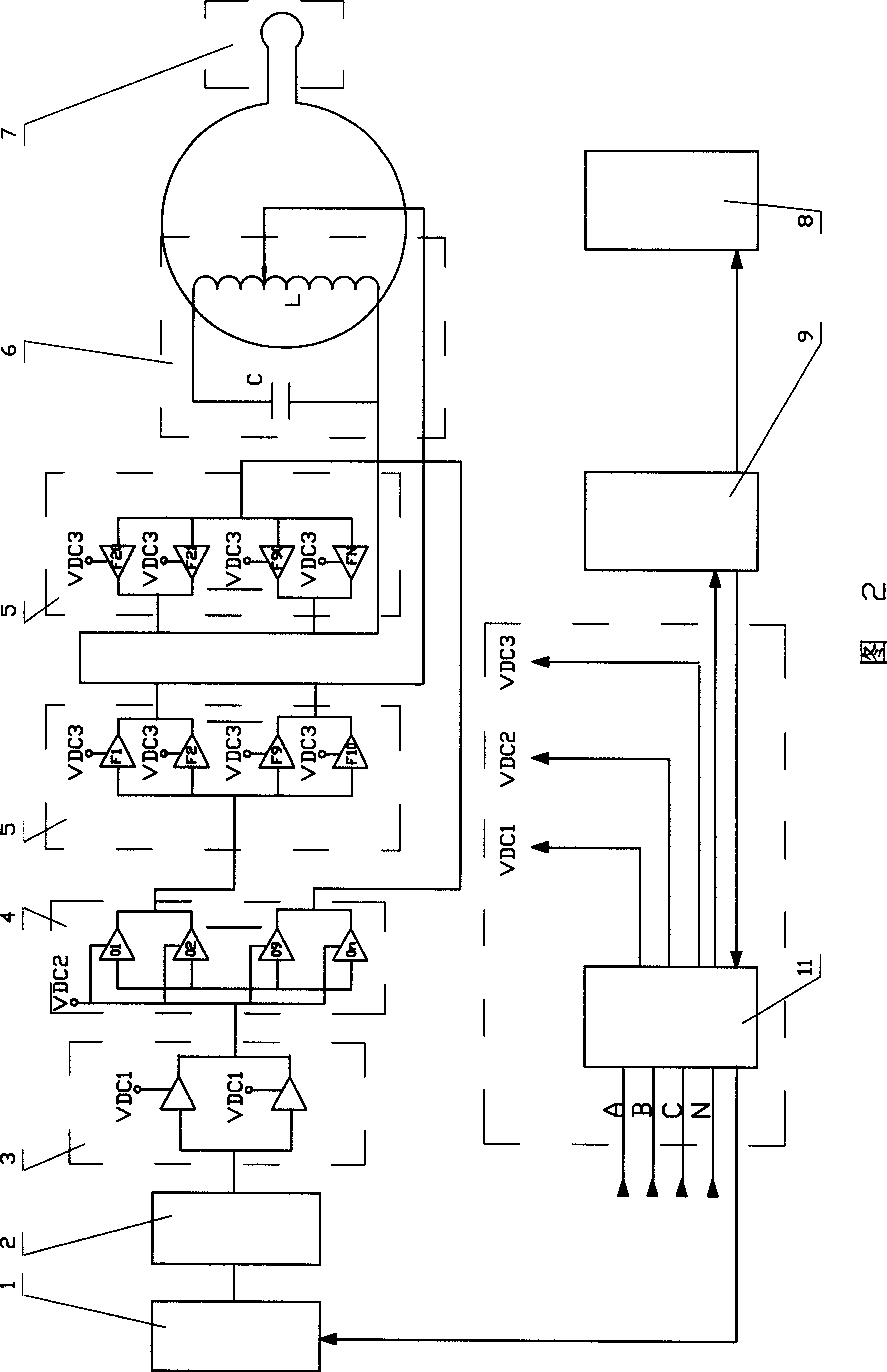

[0013] As shown in Figure 2, the 380V three-phase AC power supplies power to the pre-driver stage 3, driver stage 4, and power amplifier stage 5 through the step-down transformer and bridge rectifier circuit 11 from the distribution network, and supplies power to the control circuit 9 and the frequency converter at the same time. The control circuit 1 provides power. The frequency control circuit 1 connects the output of the frequency signal required for the operation of the equipment to the input of the buffer stage 2, and the buffer stage 2 connects the output of the adjusted frequency signal power to the input of each power module unit in the pre-driver stage 3, and the pre-stage The driver stage 3 is composed of multiple power module unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com