Method for etching inclined shoulder type side wall in large scale integrated circuit logic device

A large-scale integrated circuit and logic device technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve the problems of polysilicon gate pitch size PMD deposition voids and other problems, achieve good in-plane uniformity, and maintain in-plane Uniformity, the effect of reducing the probability of void generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

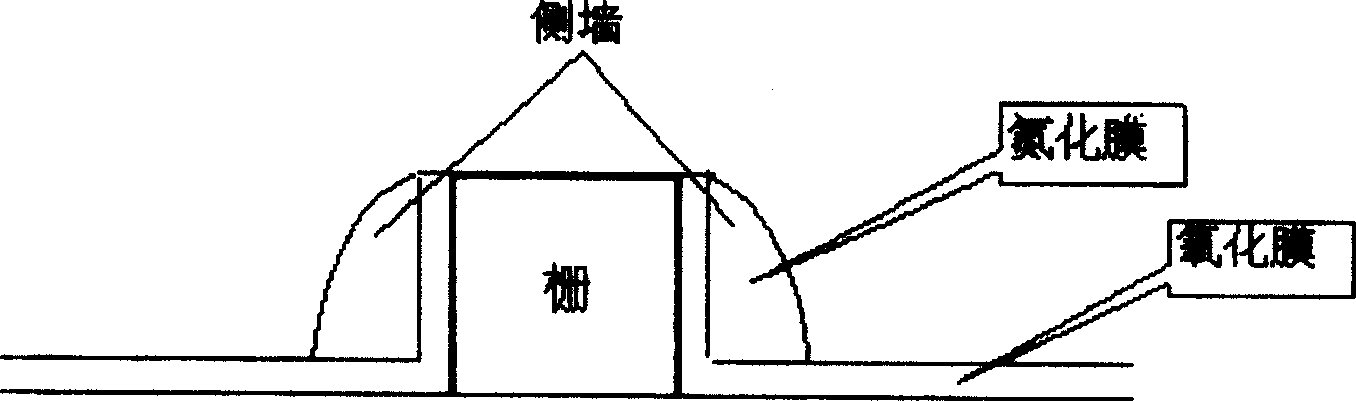

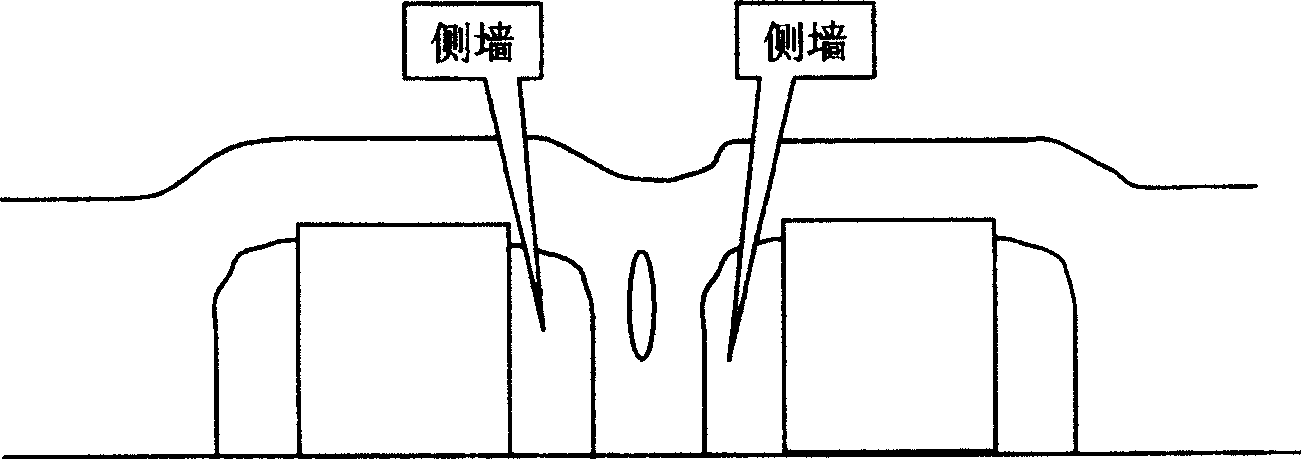

[0020] The etching method of the sloping shoulder type sidewall in the VLSI logic device of the present invention comprises the following steps: Step 1, carry out lightly doped drain implantation process; Step 2, deposit dielectric film on gate (polysilicon), deposit first A layer of oxide film (SiO 2 ), and then deposit a layer of nitride film (SiN) (such as figure 1 shown); step 3, remove most of the dielectric film with plasma dry etching, and form sidewalls on the sides of the gate (such as figure 2 shown).

[0021] Since the etching of the side wall holes needs to etch the nitride film (SiN) and the oxide film (SiO) sequentially from top to bottom. 2 )(Such as figure 1 shown), so for films of different materials, corresponding etching conditions are used, and step 3 is specifically divided into the following two steps:

[0022] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com