Control method for the field intensity at the compound insulator end and compound insulator

A composite insulator and control method technology, applied in organic insulators, insulators, rubber insulators and other directions, can solve the problems of shortening the impact withstand voltage level of composite insulators, hidden dangers of engineering construction and safe operation, and increasing the size of towers, and solve the project cost. The effect of increasing, improving the withstand voltage margin, and reducing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

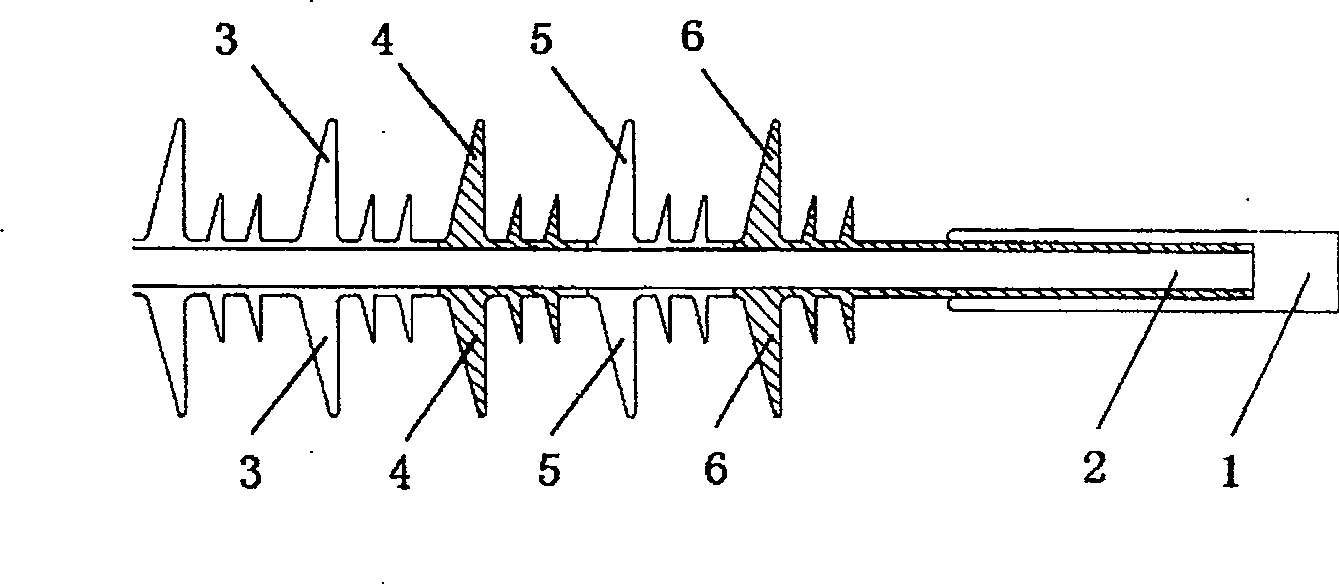

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

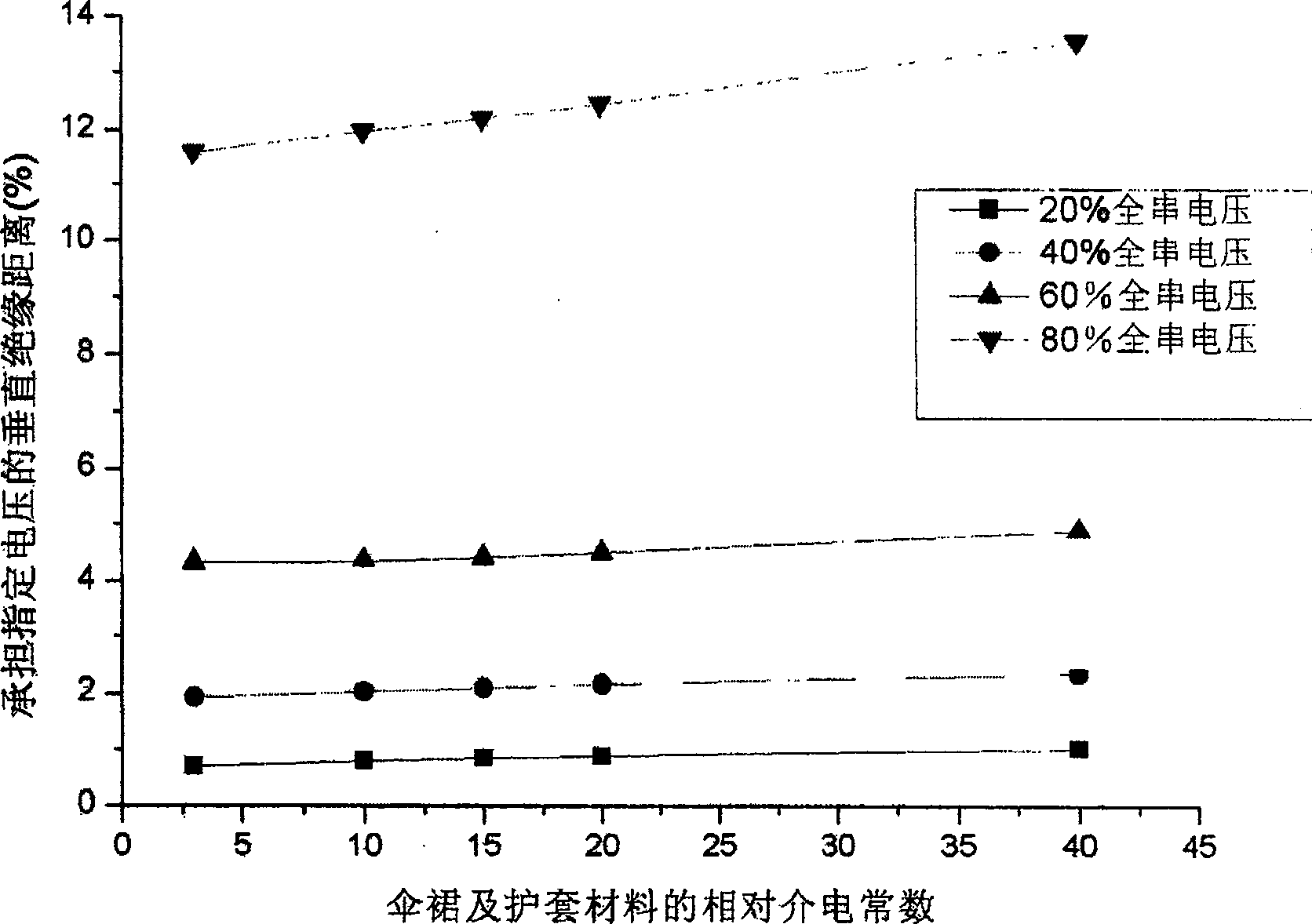

[0014] The composite insulator involved in the present invention comprises a mandrel, metal fittings at both ends of the mandrel, an umbrella shed and a sheath covered outside the mandrel. The relative dielectric constant of room temperature vulcanized silicone rubber used in conventional composite insulator shed and sheath materials is about 3. Doping aluminum powder and barium titanate powder in conventional vulcanized silicone rubber can increase the dielectric constant of the material, correspond to different doping volumes, and control the shape and distribution of particles, and a new type of silicone rubber with a relative dielectric constant of 40 can be obtained. Material.

[0015] In order to reduce the field strength at the end of the composite insulator, the method of the present invention takes the following steps: use high dielectric constant silicon rub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com