Method and device for controlling the supply of lubricant to the cylinder bearing face of a piston of a reciprocating engine

A piston engine and lubricant technology, which is applied in the direction of engine lubrication, lubricant pressure control, pressure lubrication safety device, etc., can solve the problems of not being able to know the lubricant supply indication of the monitoring cylinder working face, and achieve saving The effect of lubricant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

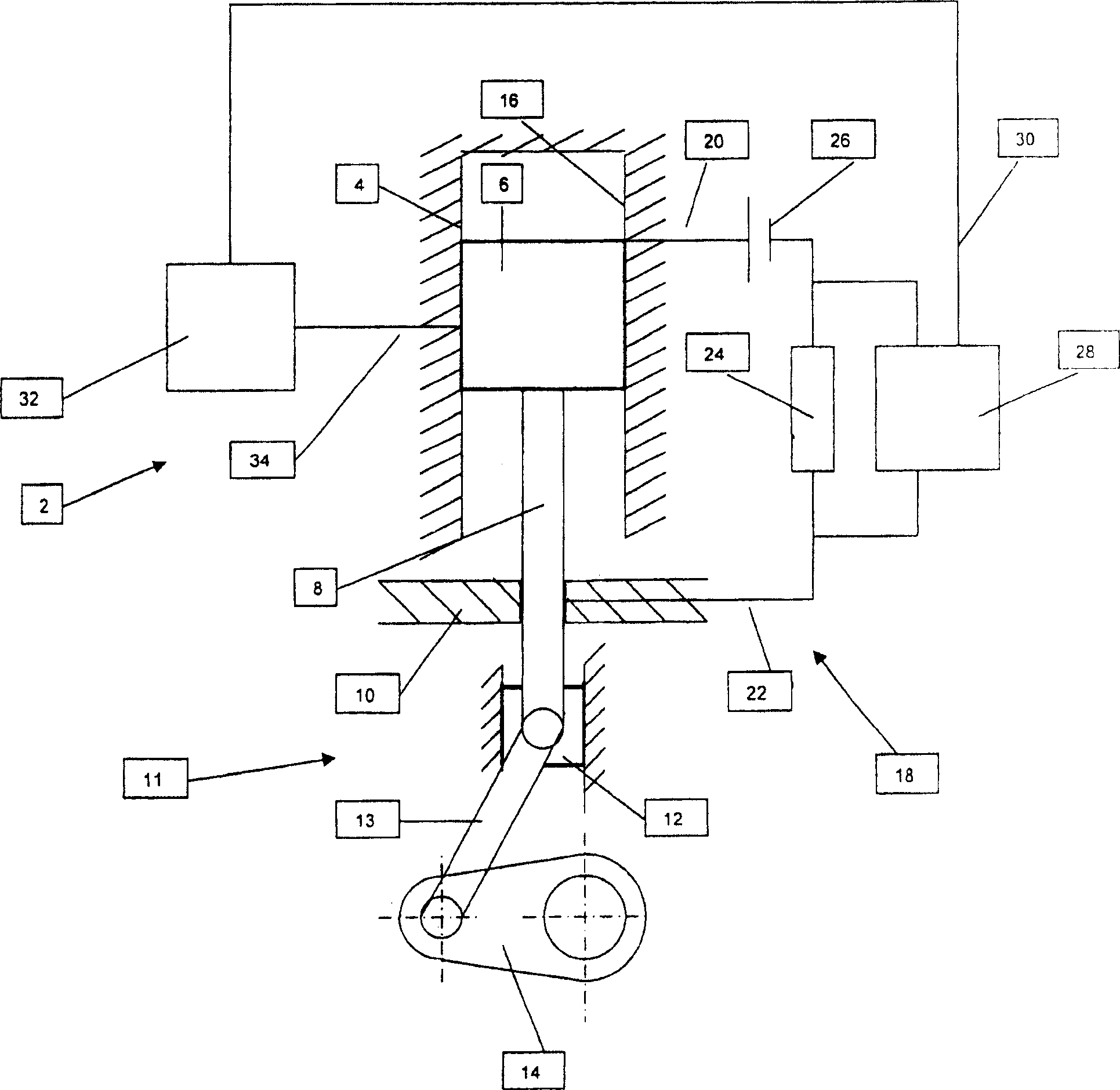

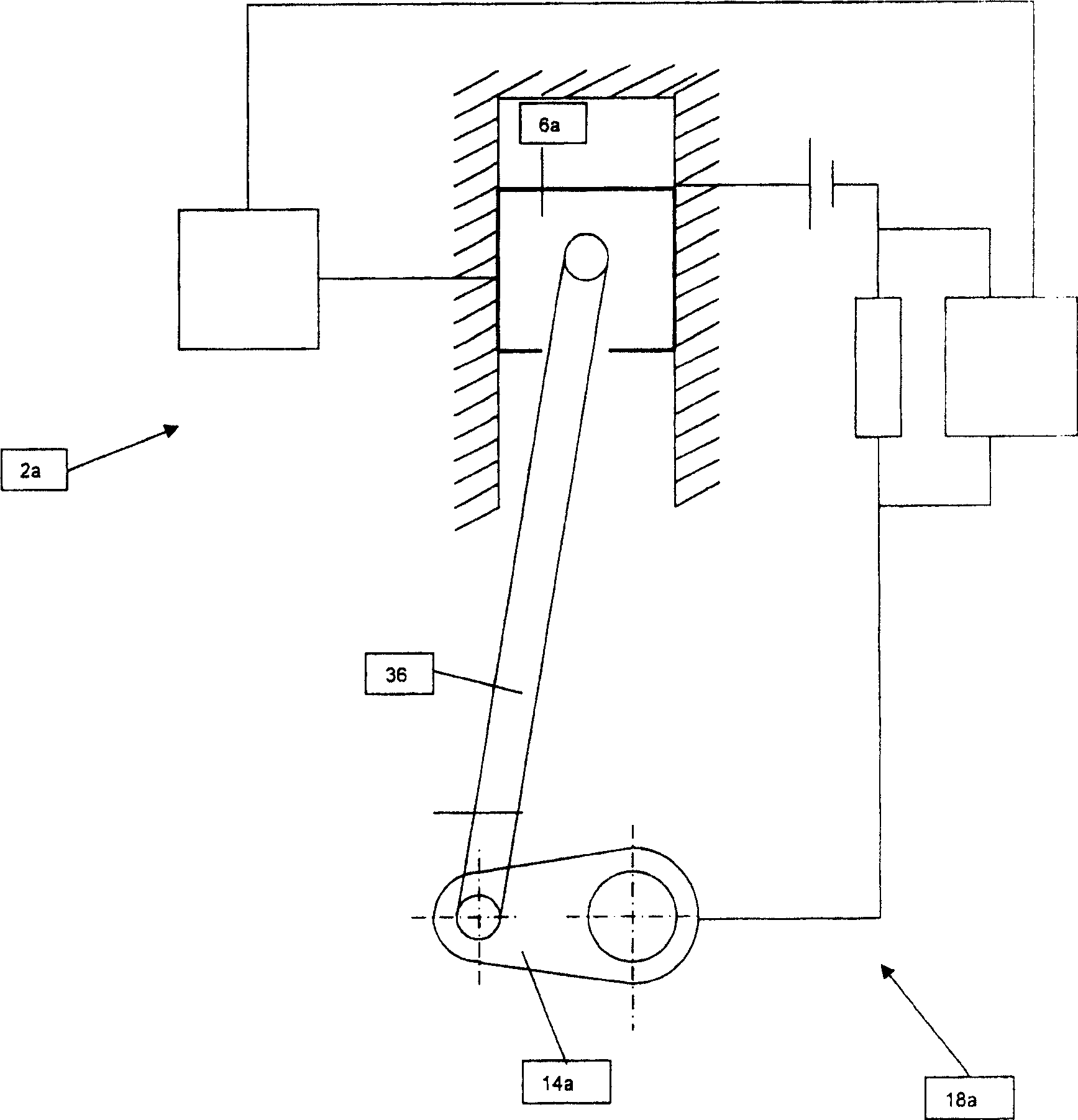

[0019] figure 1 A typical system diagram showing a piston engine 2 in which a piston 6 can move up and down in a cylinder 4 . The piston 6 is mounted on a piston rod 8 which is movably mounted in a fixed guide 10 . In the example shown, the guide device 10 is designed as a sealing sleeve, which forms a gas-tight arrangement between the underside of the piston 6 and the crankcase 11 . The lower end of the piston rod 8 is connected to the crankshaft 14 via a connecting piece 13 provided with a slider 12 .

[0020] In order to monitor the lubricant film between the piston 6 and the cylinder face 16 of the cylinder 4, there is an electrical circuit 18 in which a wire 20 is connected to the cylinder wall of the cylinder 4 and another wire 22 to the current collector of the piston rod 8 The active sealing sleeve 10 is connected. For this purpose, the gland 10 is electrically insulated with respect to the engine material. According to a further refinement not shown in the figure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com