Composite phase-change catalyst for preparing quartz and use

A composite phase change and catalyst technology, applied in physical/chemical process catalysts, glass manufacturing equipment, manufacturing tools, etc., can solve problems affecting product performance, low conversion rate, accelerated quartz conversion, etc., to solve the contradiction between supply and demand, calcination temperature Low, high-conversion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A composite phase change catalyst for preparing cristobalite, which is composed of KCl powder and MoO 3 Powder composition, KCl powder and MoO 3 The mass ratio of powder is: 9:3. The KCl powder is analytically pure.

[0022] The above-mentioned composite phase change catalyst is applied as follows (i.e. application example 1):

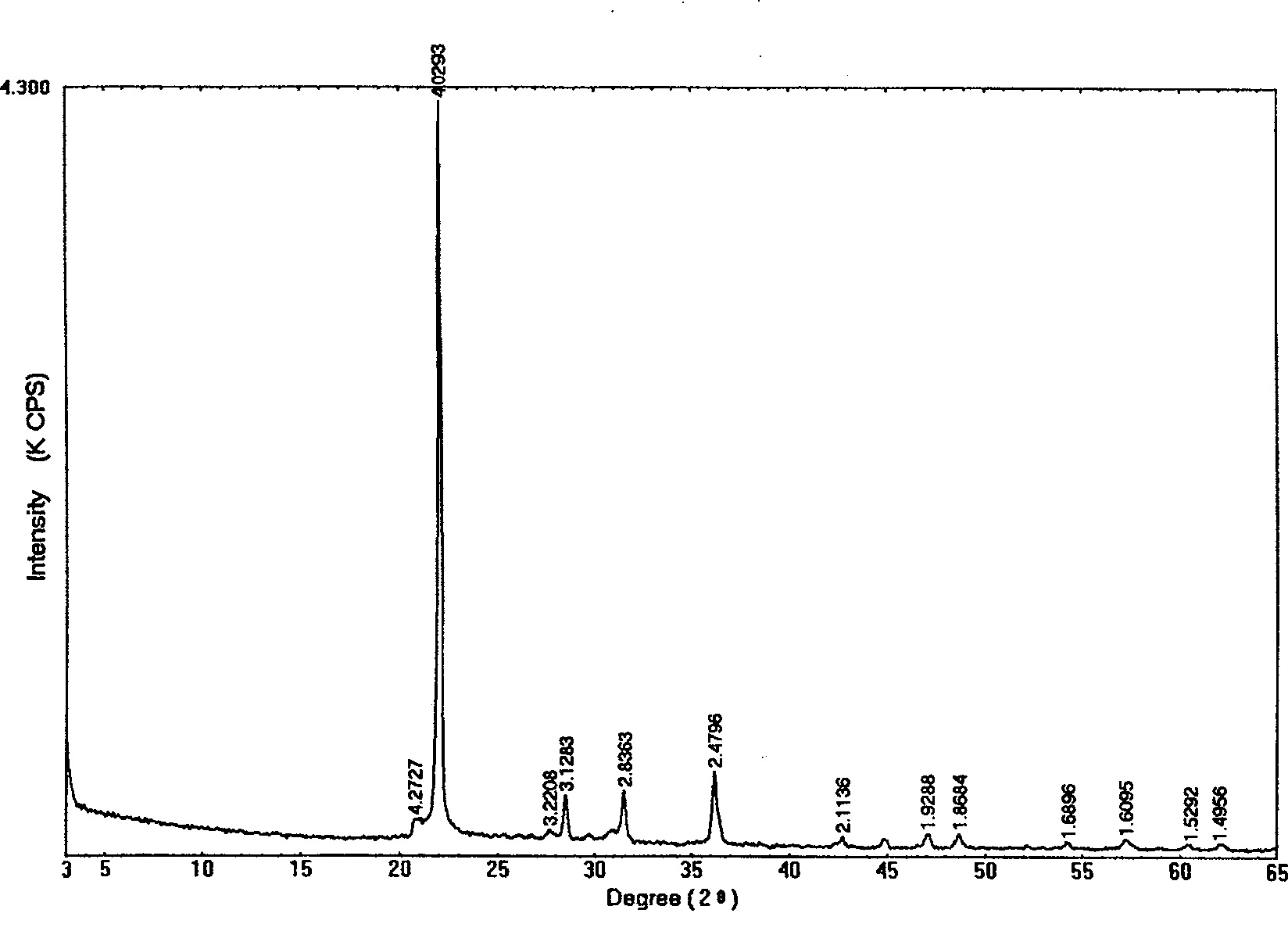

[0023] First, the Fujian Datian quartz was coarsely crushed with a jaw crusher, and then the quartz block sample was ground for 10 minutes by a rapid grinder. The obtained sample was passed through a 100-mesh sieve (less than 0.149mm), and 5.00 g of quartz powder was put into corundum. In the crucible, add a composite phase change catalyst (ie, 3‰ molybdenum trioxide, 9‰ analytically pure potassium chloride) with a quartz powder mass of 12‰, mix evenly, and put it in a silicon-molybdenum rod box-type resistance furnace. The temperature was raised to 1300 °C at a rate of 4 °C, and the temperature was kept at 1300 °C for 6 hours. From the X-ray...

Embodiment 2

[0025] A composite phase change catalyst for preparing cristobalite, which is composed of KCl powder and MoO 3 Powder composition, KCl powder and MoO 3 The mass ratio of powder is: 8:4. The KCl powder is analytically pure.

[0026] The above-mentioned composite phase change catalyst is applied as follows (i.e. application example two):

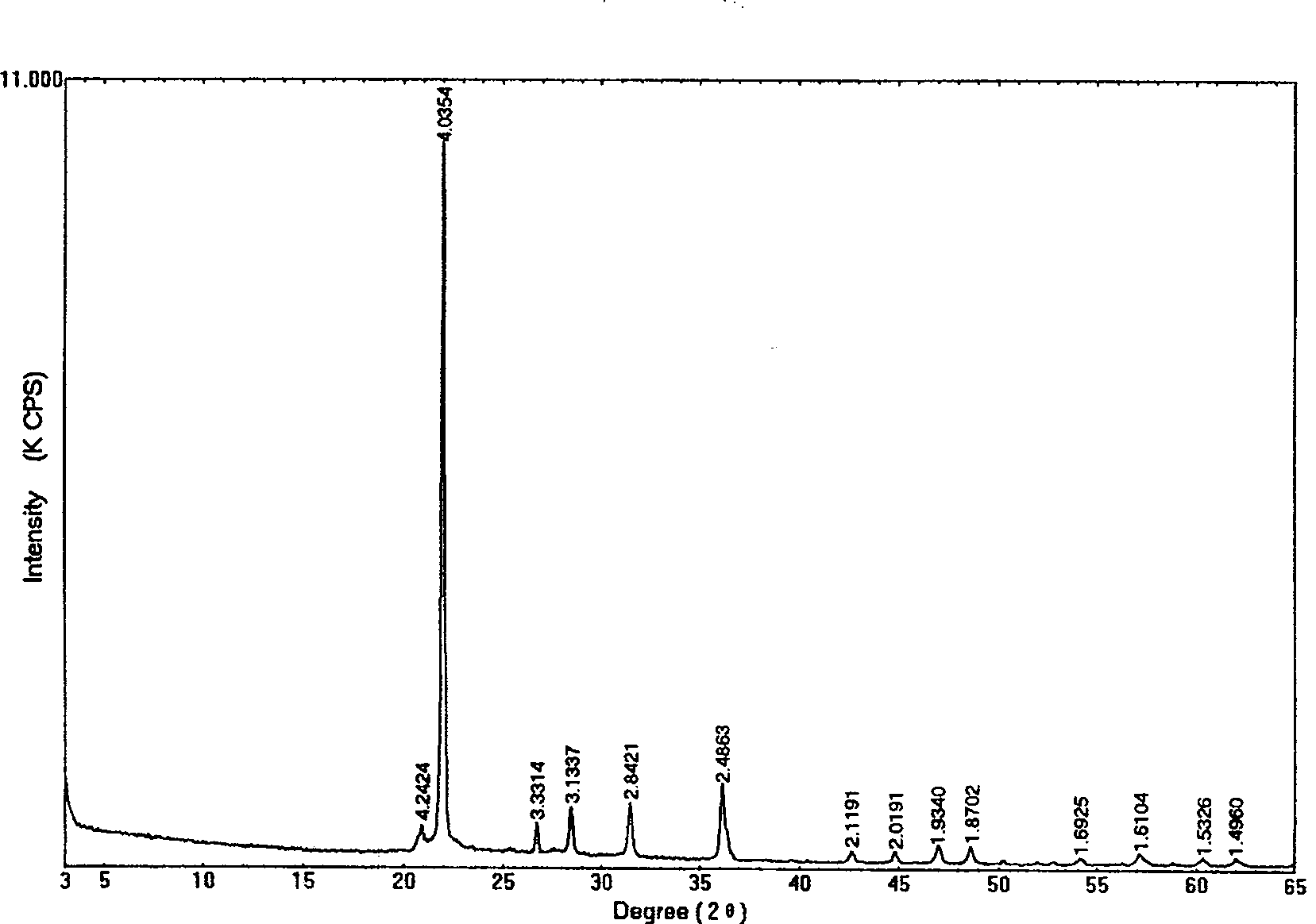

[0027] First, the Fujian Datian quartz was coarsely crushed with a jaw crusher, and then the quartz block sample was ground for 10 minutes by a rapid grinder. The obtained sample was passed through a 100-mesh sieve (less than 0.149mm), and 5.00 g of quartz powder was put into corundum. In the crucible, add a composite phase change catalyst with a mass of 12‰ of quartz powder (ie, 4‰ molybdenum trioxide, 8‰ analytical pure potassium chloride), mix evenly, and put it in a silicon-molybdenum rod box-type resistance furnace. The temperature was raised to 1300 °C at a rate of 4 °C, and the temperature was kept at 1300 °C for 6 hours. From the X-...

Embodiment 3

[0029] A composite phase change catalyst for preparing cristobalite, which is composed of KCl powder and MoO 3 Powder composition, KCl powder and MoO 3 The mass ratio of powder is: 7:5. The KCl powder is analytically pure.

[0030] The above-mentioned composite phase change catalyst is applied as follows (i.e. application example three):

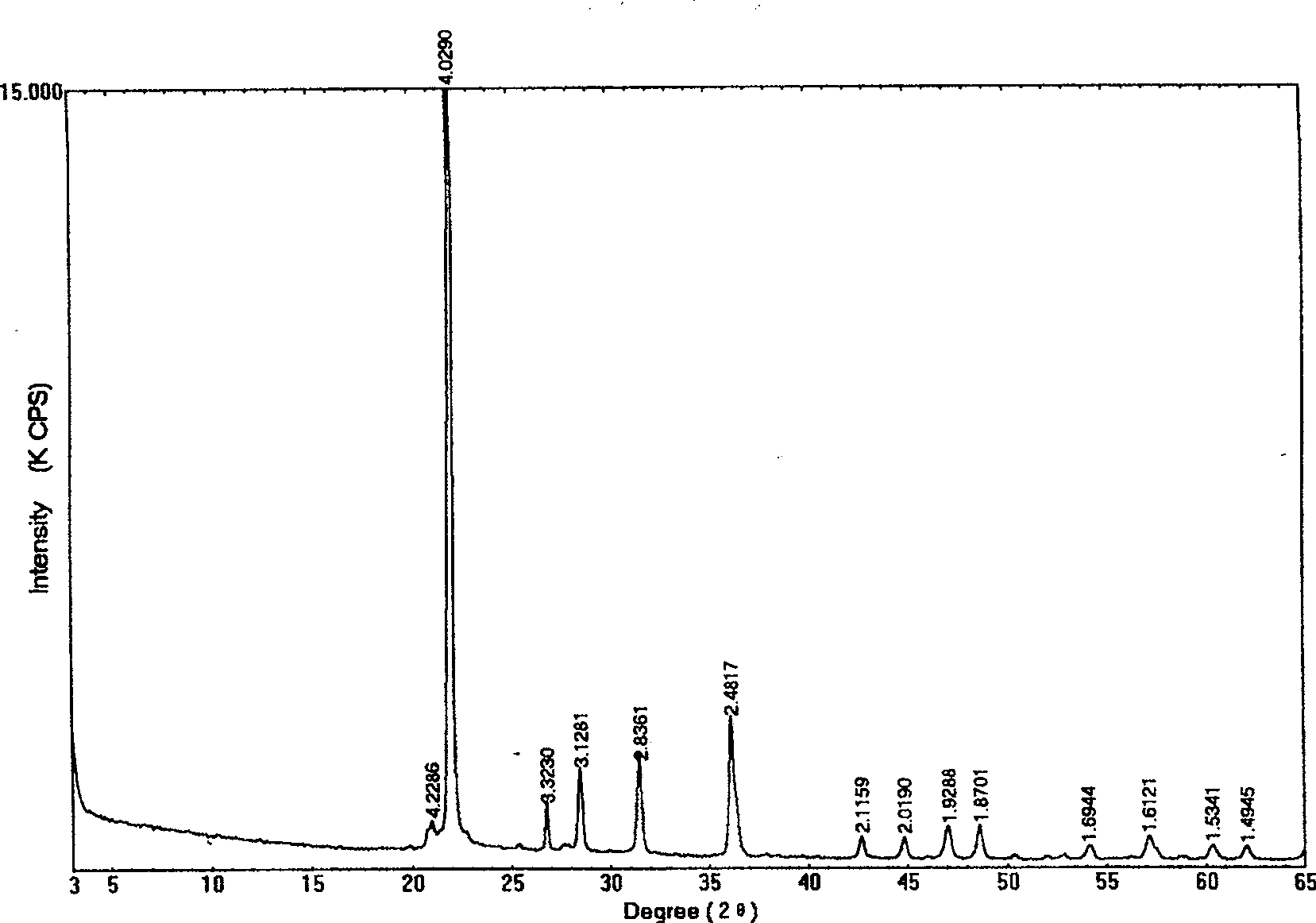

[0031] First, the Fujian Datian quartz was coarsely crushed with a jaw crusher, and then the quartz block sample was ground for 10 minutes by a rapid grinder. The obtained sample was passed through a 100-mesh sieve (less than 0.149mm), and 5.00 g of quartz powder was put into corundum. In the crucible, add a composite phase change catalyst with a mass of 12‰ of quartz powder (ie, 5‰ molybdenum trioxide, 7‰ analytical pure potassium chloride), mix evenly, and put it in a silicon-molybdenum rod box-type resistance furnace. The temperature was raised to 1300 °C at a rate of 4 °C, and the temperature was kept at 1300 °C for 6 hours. From the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com