A method for equable glue filling of LED and corresponding glue filler

A technology of light-emitting diodes and glue filling machines, applied in the field of glue filling machines, can solve the problems of difficult control of gap accuracy, influence of glue injection uniformity, large gap, etc., to achieve the effects of reducing difficulty, enhancing sealing and increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

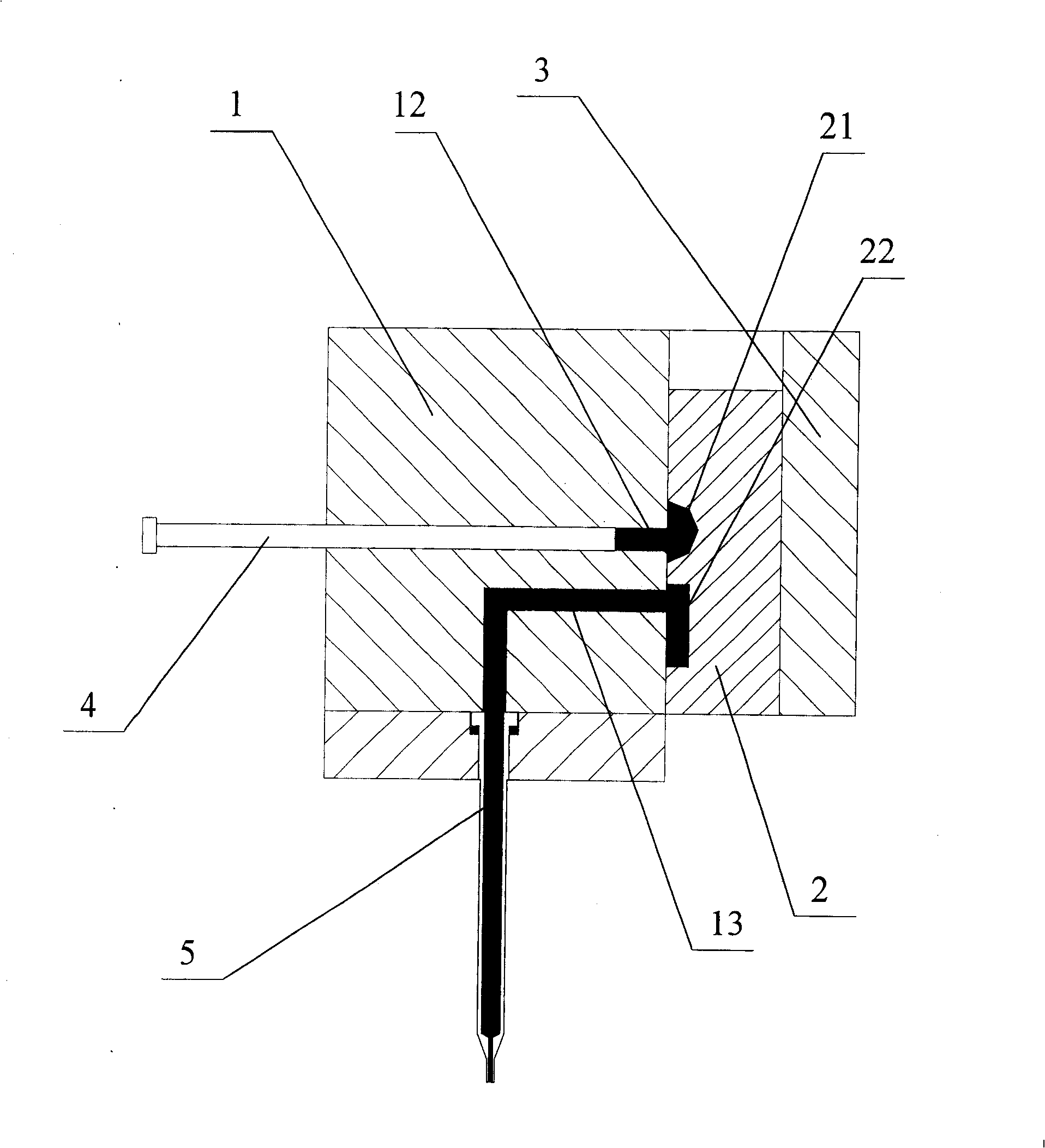

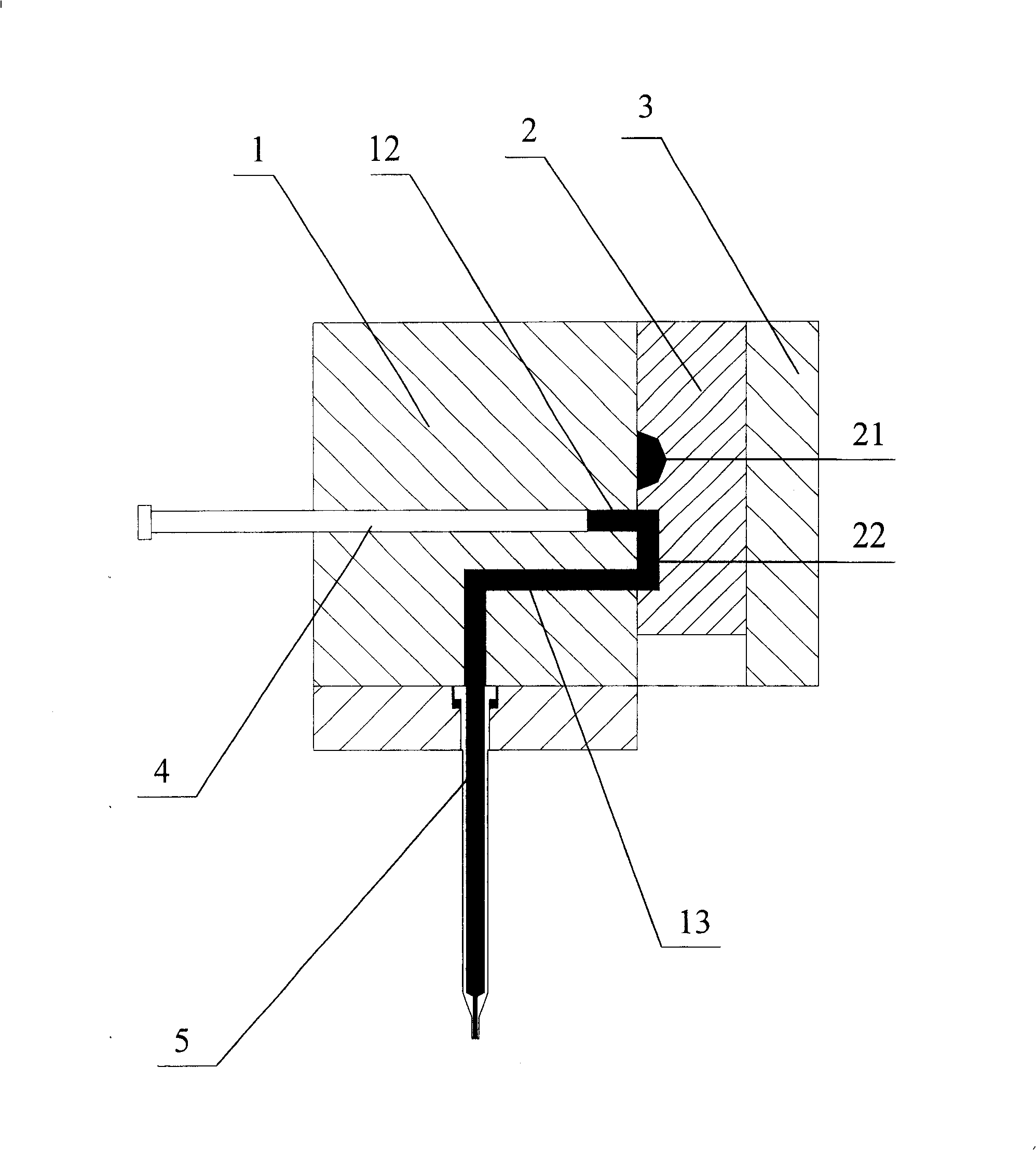

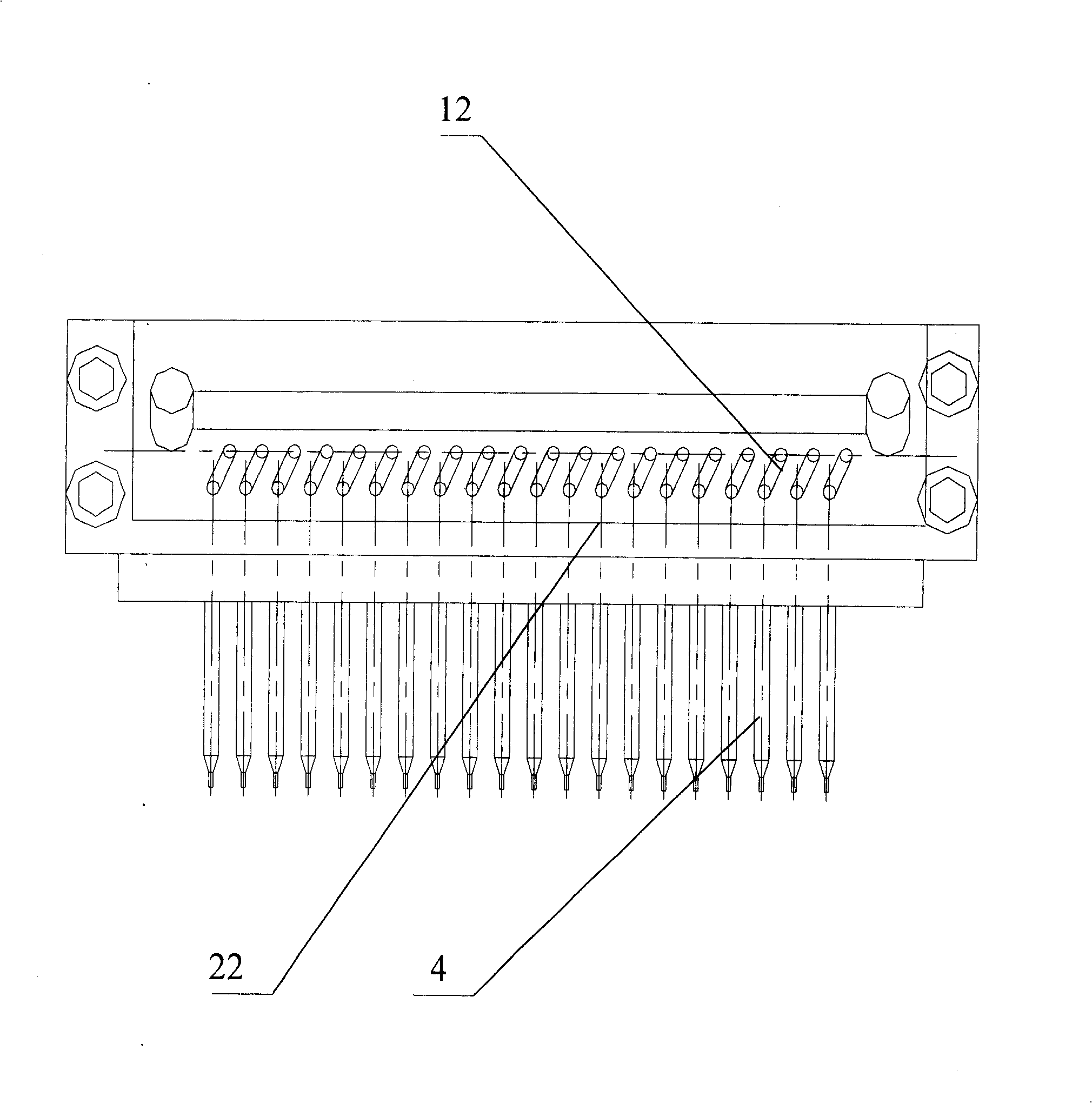

[0037] The present invention proposes a method for uniformly pouring glue on light-emitting diodes, please refer to figure 1 with figure 2 , Is the longitudinal section view of the glue pouring machine. The glue pouring machine includes a body 1 and a valve plate 2, and an elastic plate 3 is fixed on the plate surface of the valve plate 2, which is used to compress the valve plate and maintain the valve plate. The airtightness between the plate surface and the side surface of the body; a set of piston rods 4 are connected to the power source of the stepping motor, the piston rod 4 reciprocates with the power source, and the piston rod 4 is sleeved in the material storage in the body 1 In hole 12, a feed orifice is arranged on the body, and the other end of the feed orifice is located on the side of the body; the side of body 1 is provided with a valve plate 2 that can move up and down. The valve plate 2 contains a groove 21 and a pipe. 22. The conduit 22 is located below the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com