A lead-free low-cadmium stripping quantity selenium-cadmium dye, a preparation method and a using method thereof

A pigment and weight technology, applied in the direction of inorganic pigment treatment, chemical instruments and methods, fibrous fillers, etc., can solve the problems of lack of color rendering, high product price, lack of market competitiveness, etc., to achieve pure and rich color, good market Competitive, low price effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

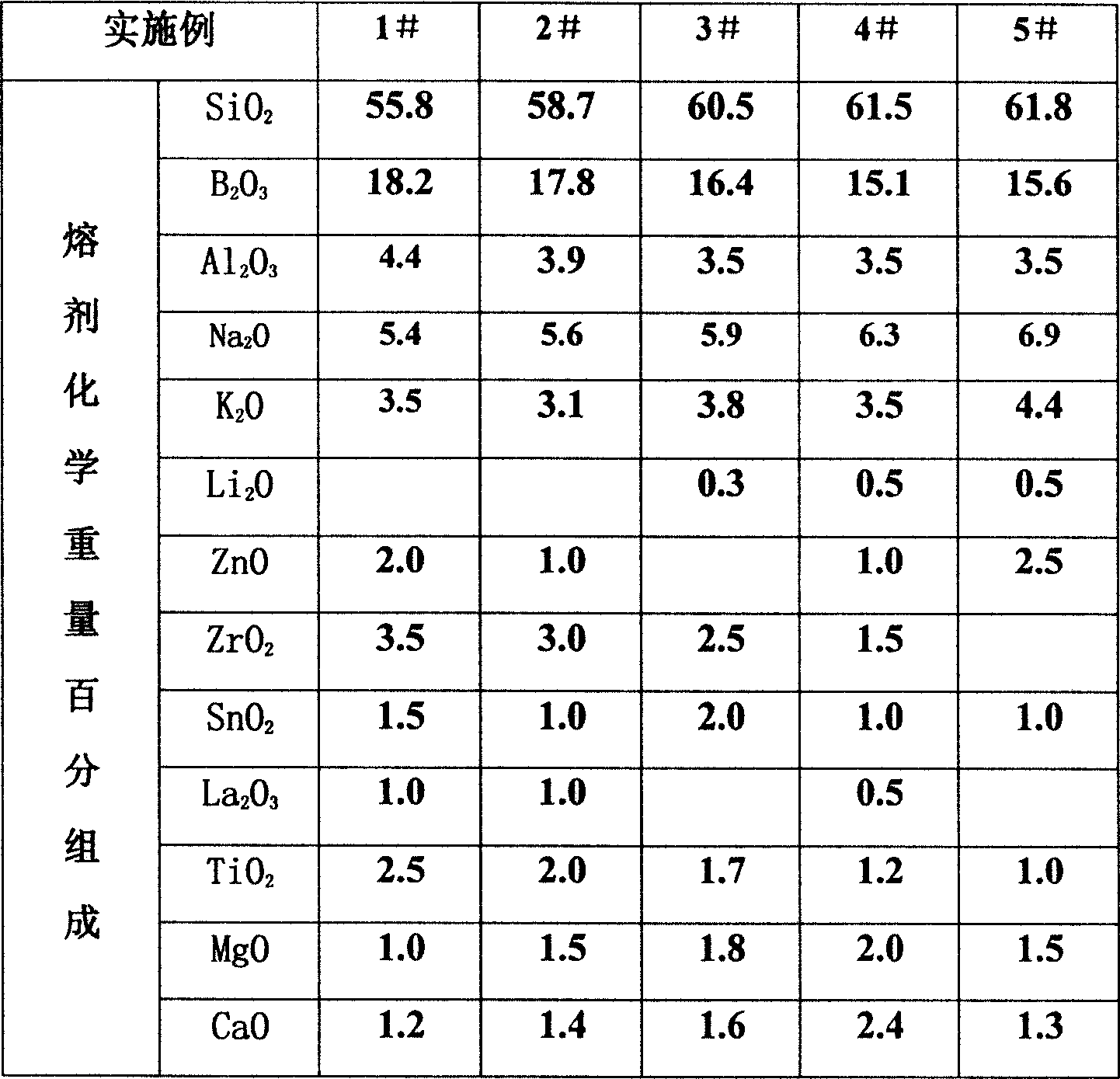

[0019] The method for preparing lead-free and low-cadmium selenium-cadmium pigments in the examples is to prepare flux and then pigments according to the composition ingredients. The following steps are:

[0020] ① Preparation of flux: mix the raw materials needed for the solvent uniformly according to the proportion, pass through a 100 mesh sieve, quench with molten water at a temperature of 1280±10℃, and dry for use;

[0021] ②Ball milling: ball mill the flux and the corresponding purchased toner until the particle size is less than 10 microns, and then dry out the mill for use;

[0022] ③Re-burning: re-burning and water-quenching the ball-milled mixture at 800±30℃;

[0023] ④Secondary grinding: Put the re-fired water quenched material into a ball mill for wet grinding until the particle size is less than 5 microns, and then grind, dry, and crush to obtain pigment products.

[0024] The method of use is basically the same as the usual pigments, except that after applying decorat...

Embodiment 9

[0036] The preparation method of the pigment, the steps are as follows:

[0037] ① Preparation of flux: mix the raw materials needed for the solvent uniformly according to the proportion, pass through an 80-mesh sieve, and quench with molten water at a temperature of 1300±30℃;

[0038] ②Ball milling: ball mill the flux and toner mixture until the particle size is less than 10 microns, and dry out the mill for use;

[0039] ③Re-burning: re-burning and water-quenching the ball-milled mixture at a temperature of 760±10℃;

[0040] ④Secondary grinding: Put the re-fired water quenched material into a ball mill for wet grinding until the particle size is less than 5 microns, and then grind, dry, and crush to obtain pigment products.

[0041] The ingredient weight of the dark emerald green pigment is divided into 100 groups:

[0042] 1# flux 85%, green agent 10% and cadmium yellow 5%;

[0043] Among them, the green agent ingredients are divided into 100% by weight: CoO 25%, chromium oxide...

Embodiment 10

[0045] The preparation method of the pigment, the steps are as follows:

[0046] ① Preparation of flux: mix the raw materials required for the solvent uniformly according to the proportion, pass through a 90-mesh sieve, and quench with molten water at a temperature of 1280±20℃;

[0047] ②Ball milling: ball mill the flux and toner mixture until the particle size is less than 10 microns, and dry out the mill for use;

[0048] ③Re-burning: re-burning and water-quenching the ball-milled mixture at a temperature of 820±10℃;

[0049] ④Secondary grinding: Put the re-fired water quenched material into a ball mill for wet grinding until the particle size is less than 5 microns, and then grind, dry, and crush to obtain pigment products.

[0050] The ingredients of the bamboo green pigment are divided into 100 groups by weight:

[0051] 3# flux 78%, green agent 8% and cadmium yellow 14%;

[0052] Among them, the green agent ingredients are divided into 100% by weight: CoO 35%, chromium oxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com