Regeneration processing device for waste lubricant oil

A processing device, a technology for waste lubricating oil, applied in the directions of lubricating composition, distillation separation, chemical instruments and methods, etc., can solve the problems of vacuum filter filter clogging, incomplete removal of impurities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

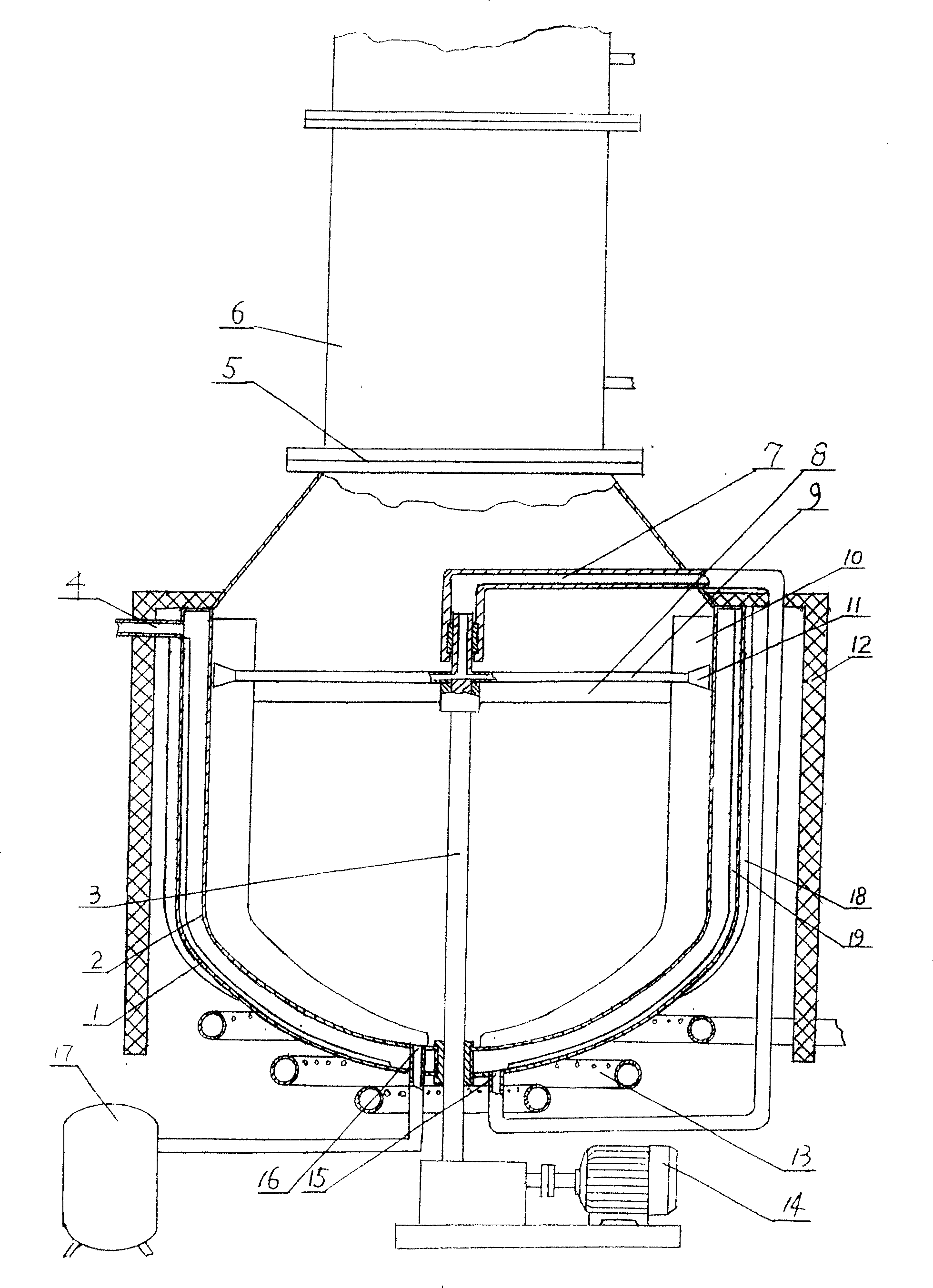

[0010] A regeneration processing device for waste lubricating oil, as shown in the attached figure, an evaporator with a closed heating interlayer is formed by an outer shell 1 and an inner tank 2, and the inner tank 2 is a combined rotary closed shell with a connecting port 5 on the upper part , The shape of the inner container 2 is a closed shell of a combined rotary body formed by a cone with a connecting port 5 on the top, a cylinder and an arc pot bottom. The connection port 5 of the liner 2 is equipped with a rectification tower 6 through a flange, and an oil inlet 4 and an oil outlet 15 are respectively arranged on the upper part and the bottom of the evaporator heating interlayer shell 1, and at the center of the bottom of the evaporator liner 2 The central rotating shaft 3 with an oil inlet hole at the upper end is installed through the sealed bearing, and the sealed bearing is installed at the end of the oil delivery pipe 7 arranged above the evaporator, the upper end...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com