Shortened interval transfer in disposable sanitary article producing line

A sanitary product and transfer device technology, which is applied in the direction of packaging, transportation and packaging, paper/cardboard containers, etc., can solve problems such as waste, achieve the effects of improving utilization rate, improving production efficiency and economic efficiency, and reasonable device design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

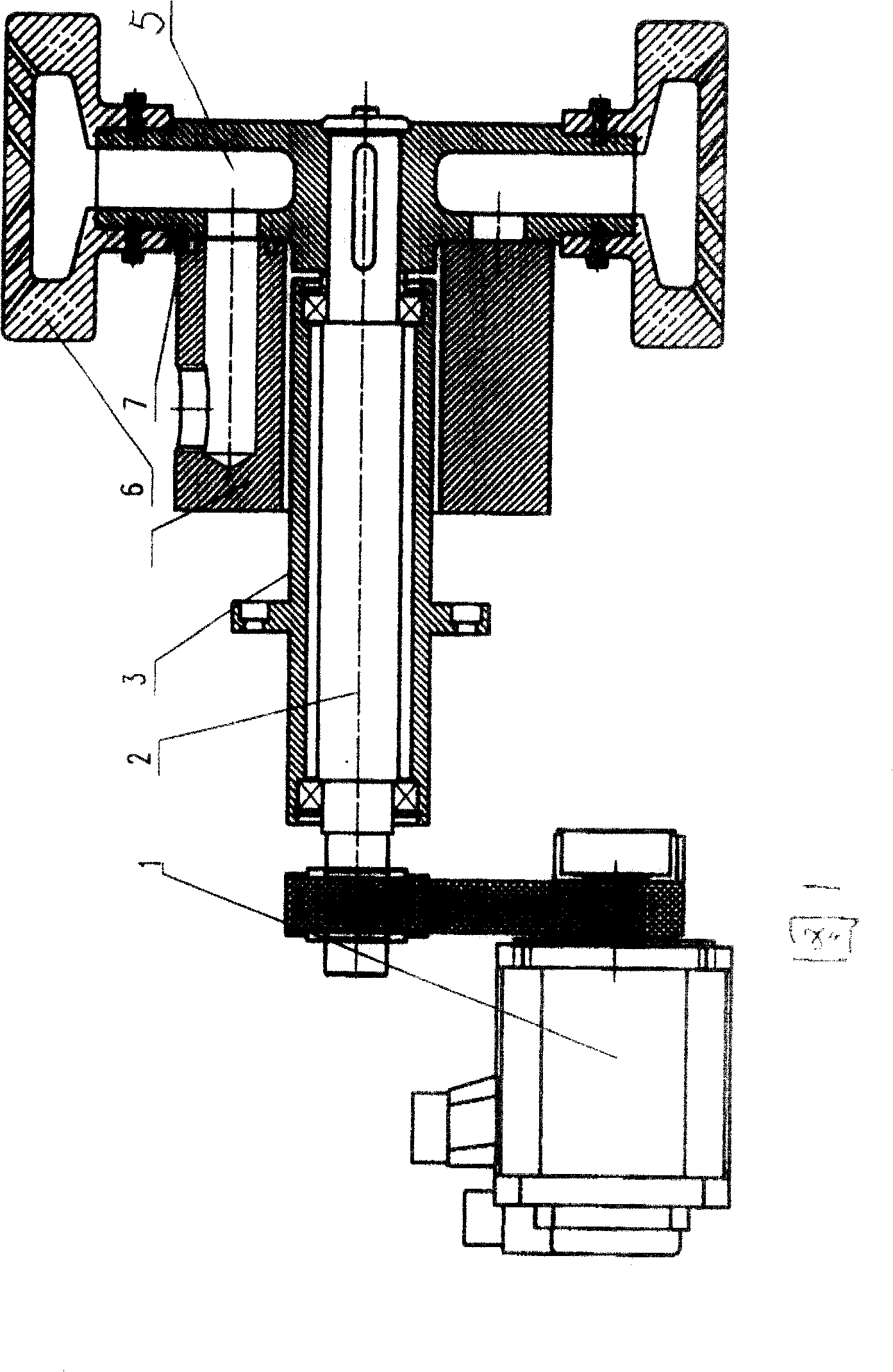

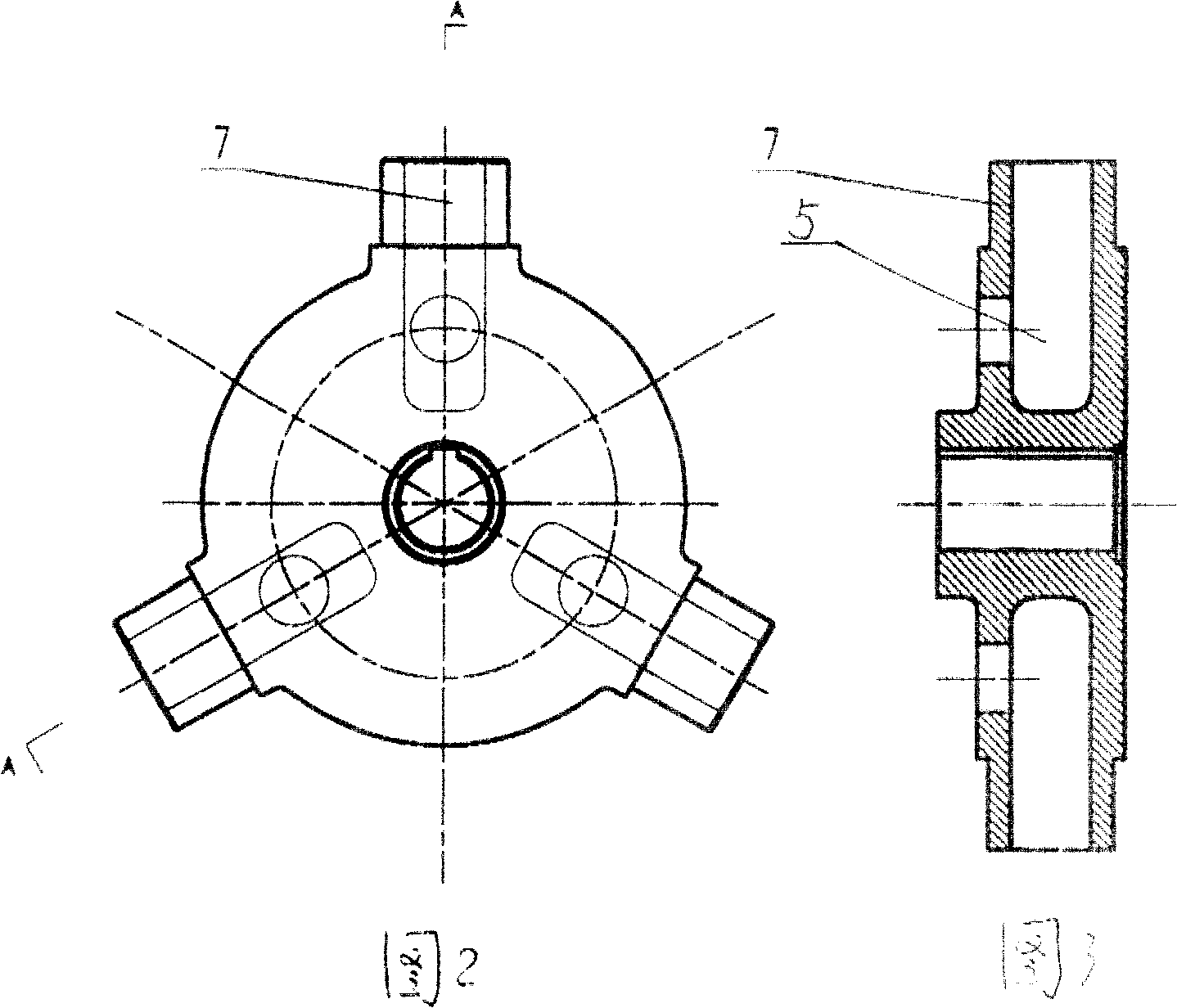

[0022] The reduced-pitch transfer device on the disposable sanitary product production line includes a servo motor 1, which is connected to the main shaft 2 through a belt transmission mechanism, and the other end of the main shaft 2 is connected to the transfer wheel 7, and the transfer wheel 7 is radially symmetrical with two radial shafts. Airway 5, the outer port of radial airway 5 is suction pipe mouth, and transfer suction head 6 is installed on the suction pipe mouth, and transfer suction head 6 is rectangular hollow cover shape, and the transfer suction head corresponding to transfer wheel 7 radial directions There are air holes evenly distributed on the end surface of 6; there is a horizontal air port on one side of the radial air passage 5, the bearing seat 3 is set on the main shaft 2, and the air valve 4 fixed on the bearing seat 3 has an annular air passage and the transfer wheel 7. The transverse airways correspond.

[0023] It works as follows:

[0024] When th...

Embodiment 2

[0026] The transfer wheel 7 is radially symmetrically opened with three radial air passages 5, the outer port of the radial air passage 5 is a suction nozzle, and the suction nozzle is covered with a transfer suction head 6, and the transfer suction head 6 and the transfer wheel 7 radial direction The corresponding outer end surface is an arc surface;

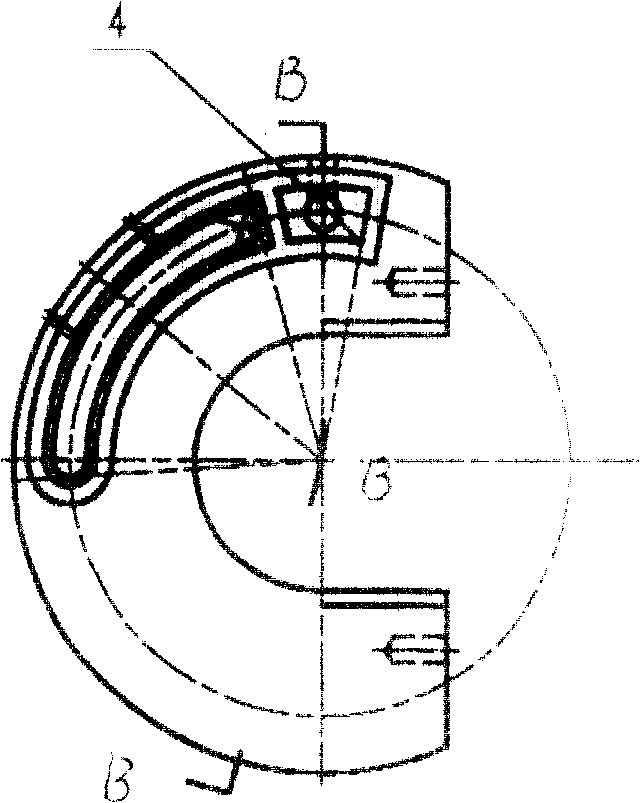

[0027] The air valve 4 is in the shape of a semi-circle, which is set on the bearing seat 3. There are two air inlets in the radial direction, and there is a through air passage between the two air inlets. The angle between the two air inlets is 60°. -260 degrees.

[0028] Other structures are with embodiment 1.

[0029] Its working principle is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com