Synthetic resin retainer and ball bearing using the same

A synthetic resin and retainer technology, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of easy deterioration of lubricating grease, rise of bearing temperature, and reduction of bearing life, so as to prevent the reduction of bearing life and prevent abnormalities Sound, anti-wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

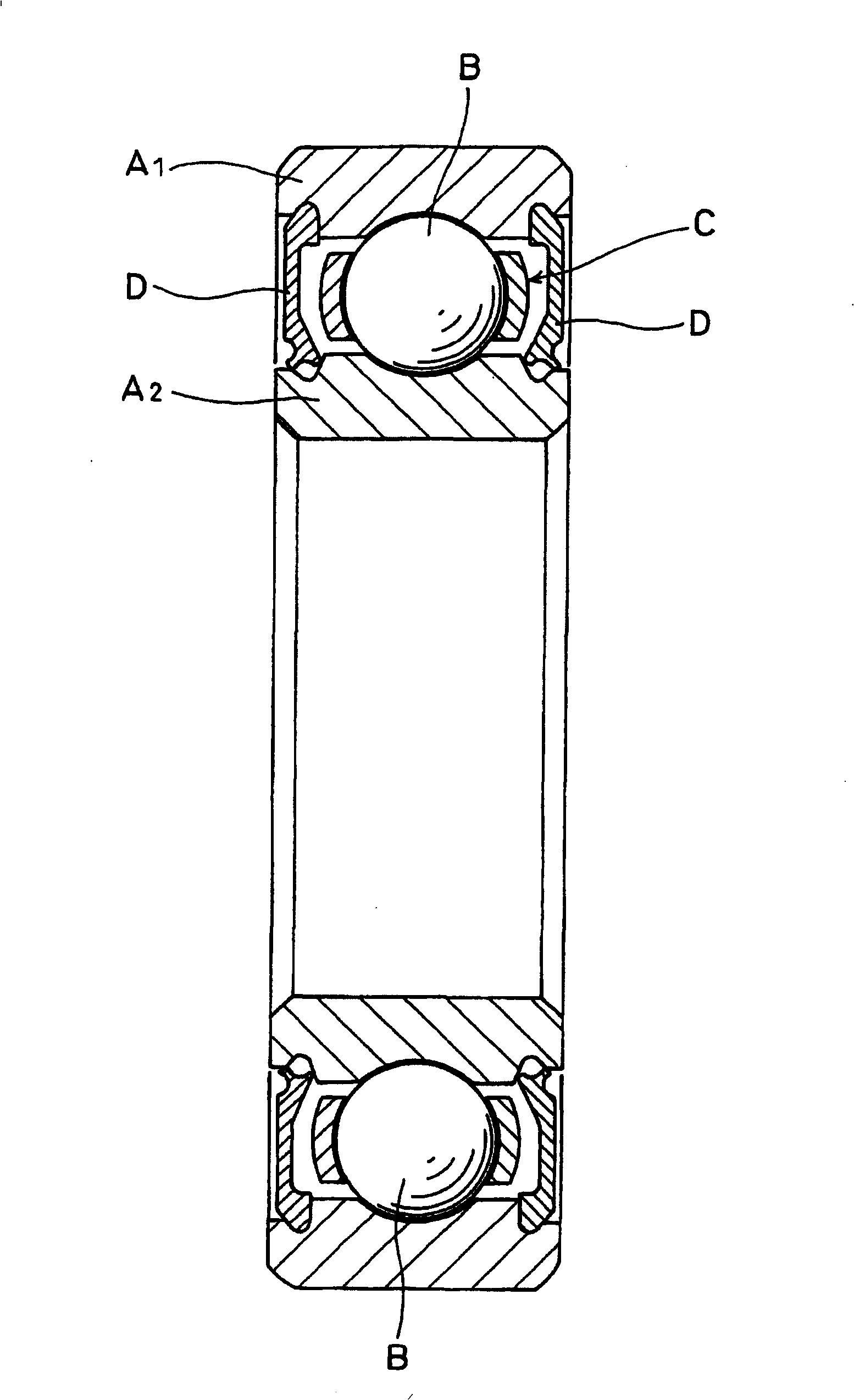

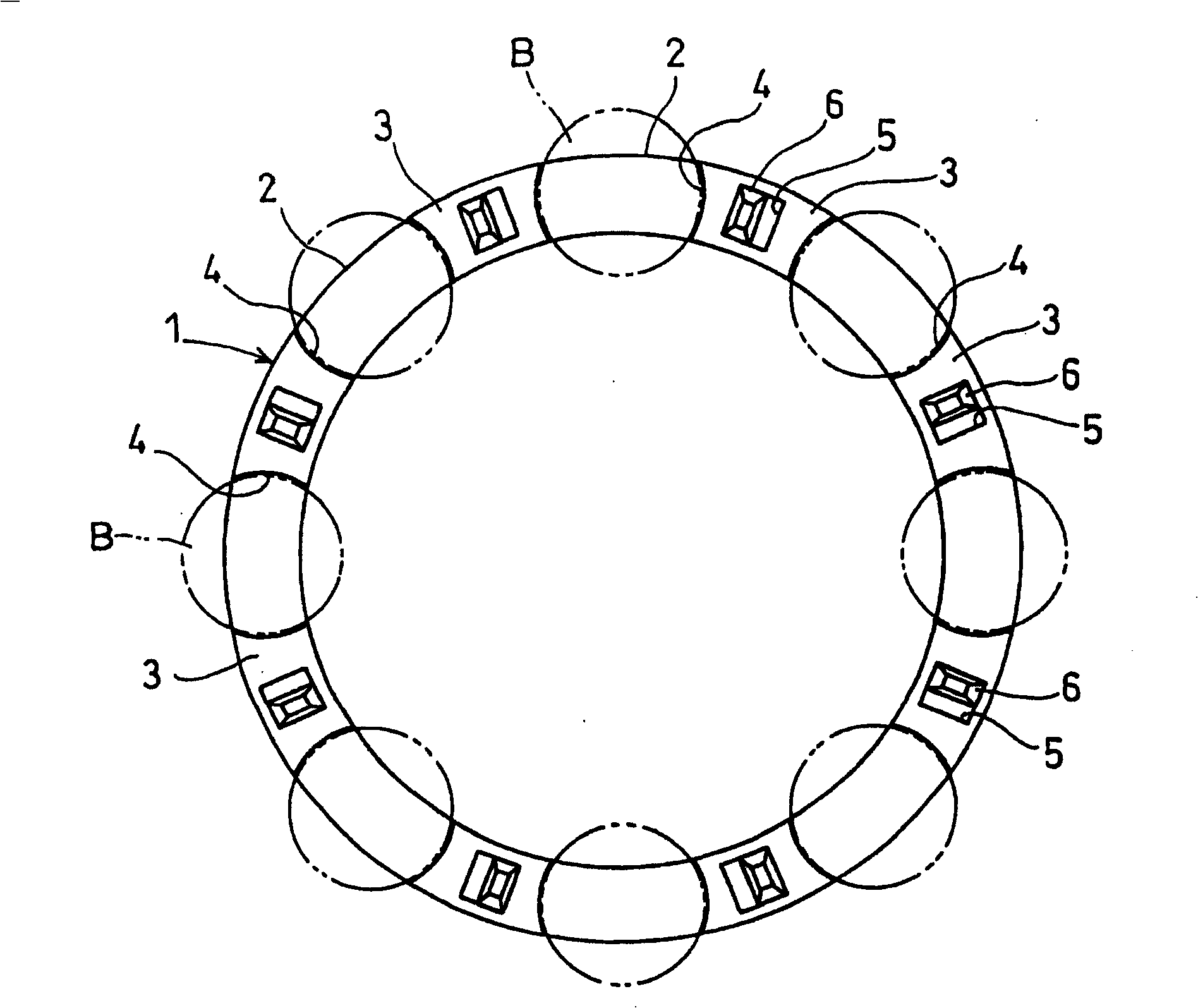

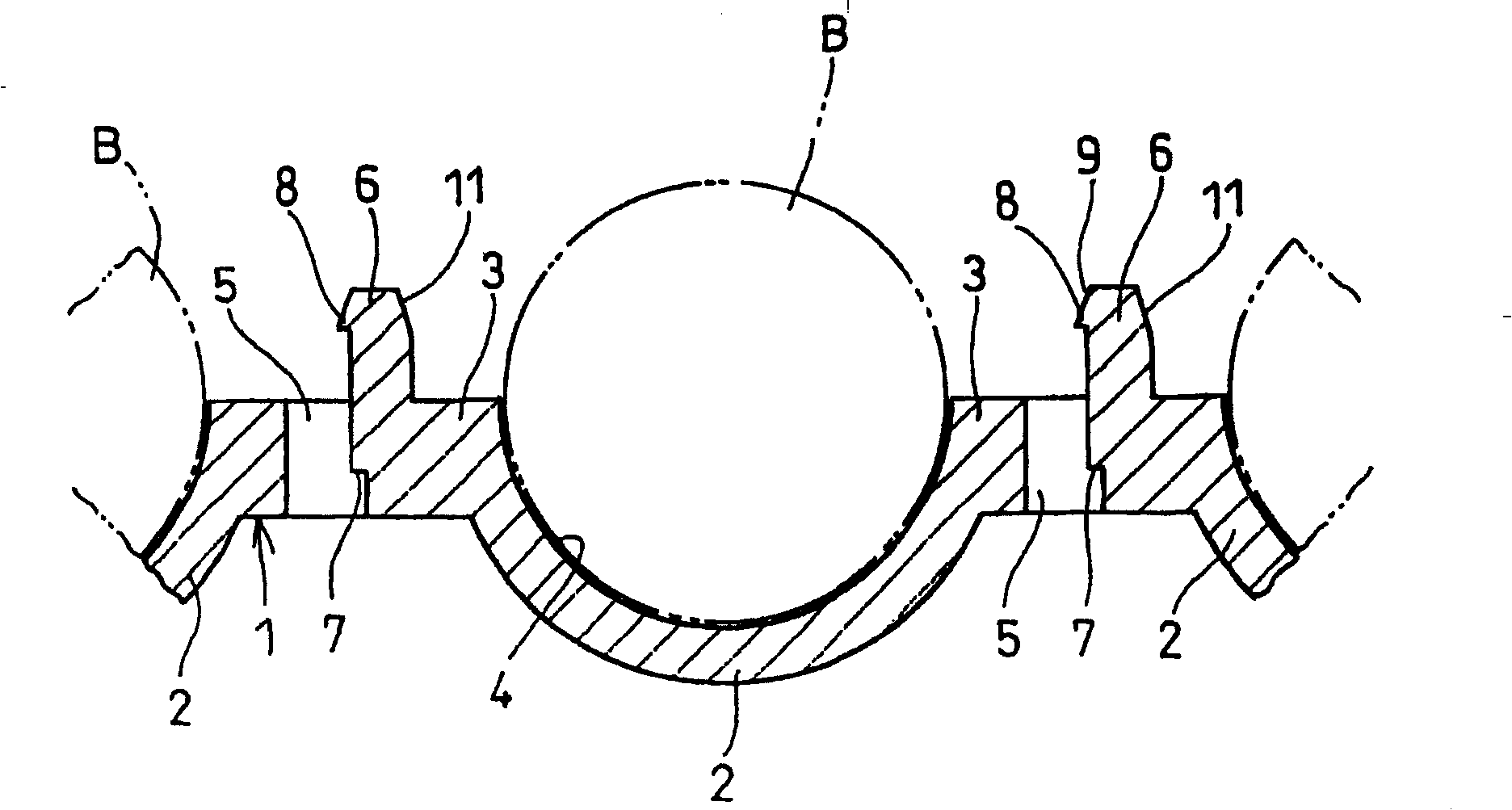

[0055] Embodiments of the present invention will be described below based on the drawings. Figure 1 to Figure 6 The first embodiment of the present invention is shown. The ball bearing has: outer ring A 1 , inner wheel A 2 , on outer wheel A 1 and inner wheel A 2 A plurality of balls B assembled between them, and a cage C that holds the balls B. retainer C as Figure 3 ~ Figure 5As shown, it consists of two annular bodies 1, 1, and each annular body 1 is formed into the same shape by molding a synthetic resin. In addition, on outer wheel A 1 and inner wheel A 2 The annular space formed between figure 1 As shown, it is sealed with bearing gasket D and sealed with grease.

[0056] Such as Figure 2 ~ Figure 4 As shown, the annular body 1 has a plurality of hemispherical ball holding parts 2 and a plurality of plate-shaped joint parts 3, the ball holding parts 2 and the joint parts 3 are formed alternately in the circumferential direction, and each ball holding part 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com