Method for brazing aluminium parts on the carbon steel part surface and aluminizing anti-rust on the non brazing surface

A non-brazing, parts technology, applied in welding media, sputtering, manufacturing tools, etc., can solve the problems of high manufacturing cost and high price of heat exchange tubes, and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

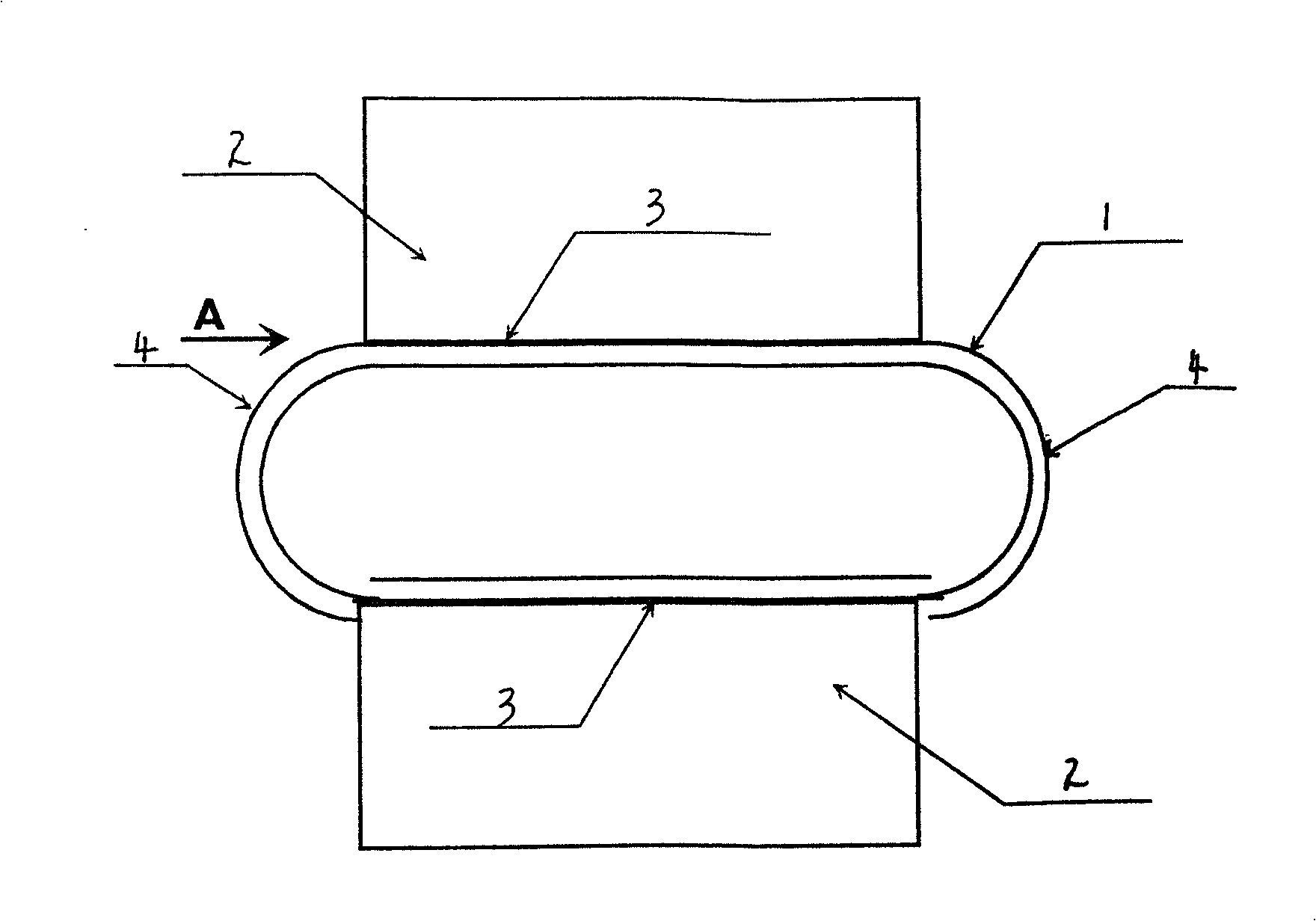

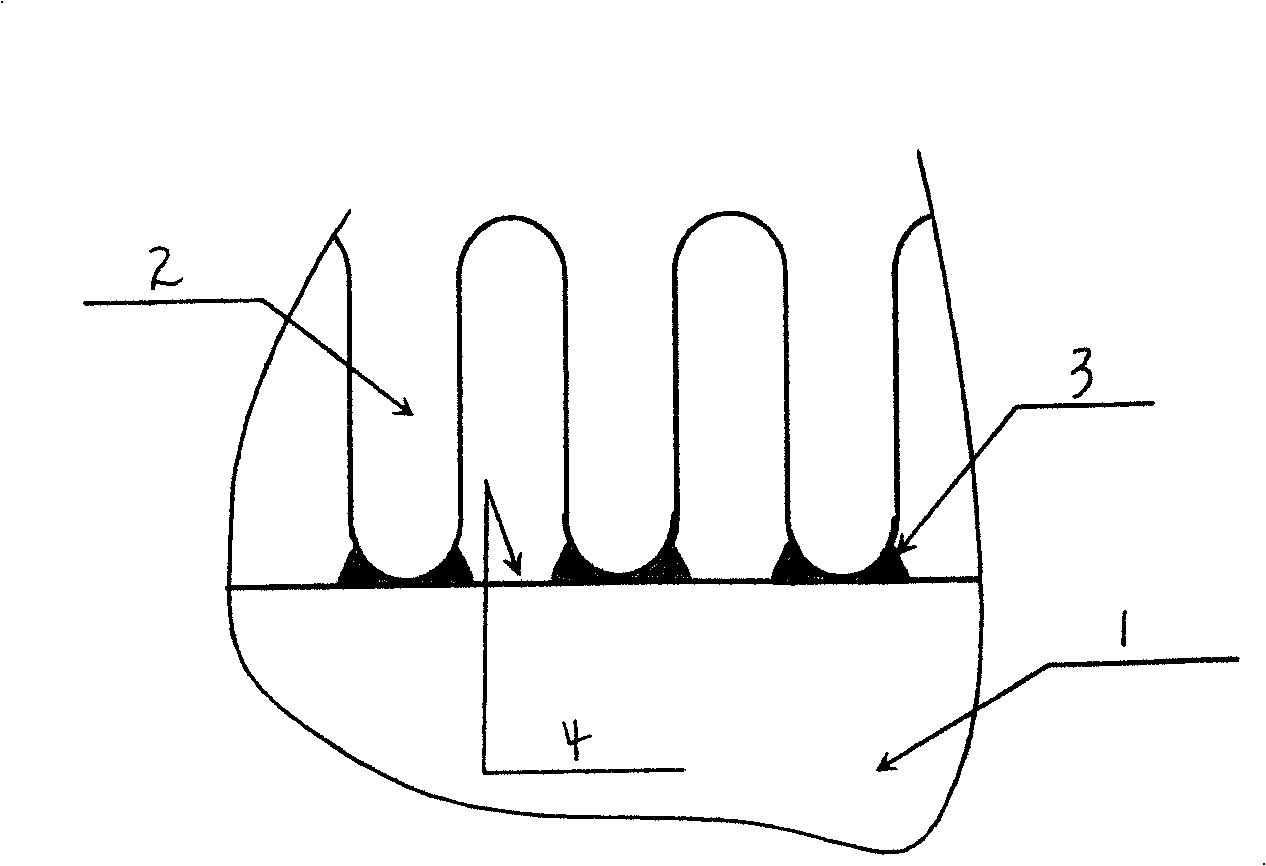

[0009] The invention relates to a compound process method for brazing aluminum parts on the surface of carbon steel parts and performing aluminum plating on non-brazing surfaces to prevent rust. Its typical application occasions are air coolers, and the schematic diagram of the finned tube structure of the air cooler is attached figure 1 , 2 shown. In the manufacturing process of the heat exchange tube of the air cooler, the heat exchange tube is made of ordinary carbon steel large flat tube 1. After rolling and welding, the surface is not subjected to any method of aluminum dipping or aluminum plating process, and the surface is coated with A layer of composite brazing filler metal. After the composite brazing filler metal is dry, aluminum fins are assembled on the upper and lower outer surfaces of the large flat tube. The assembled parts are first put into a 200℃~250℃ drying furnace to dry the parts. Drying treatment, so that the composite solder flux is fully dried, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com