Pneumatic end-face planetary motion type diamond grinding apparatus

A diamond, kinematic technology, used in grinding machines, manufacturing tools, metal processing equipment, etc., can solve the problems of difficulty in manufacturing single-layer brazed diamond grinding wheels, small size of single-layer brazed diamond grinding wheels, and no participation in processing. Small size, maintaining self-sharpening sharpness, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

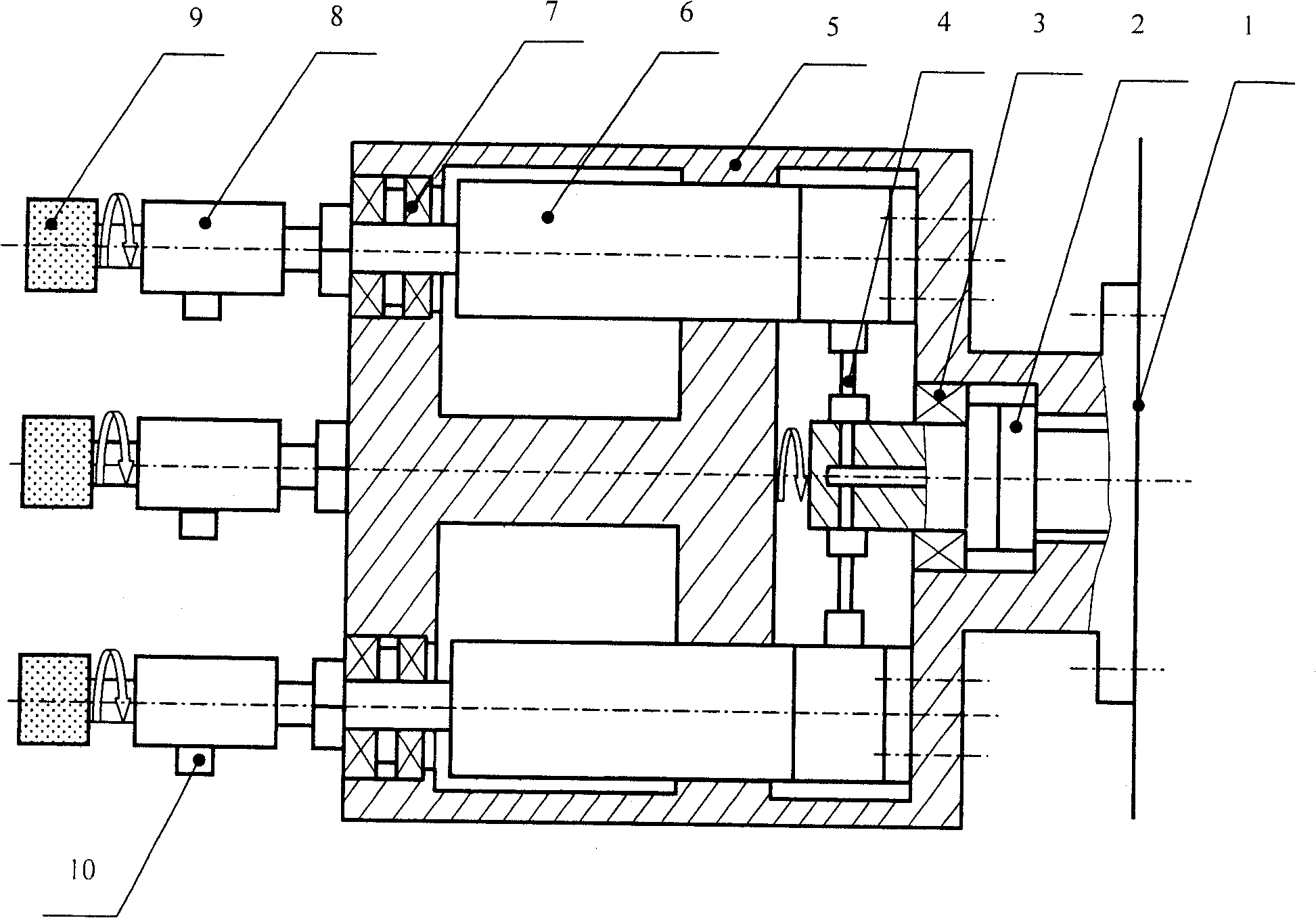

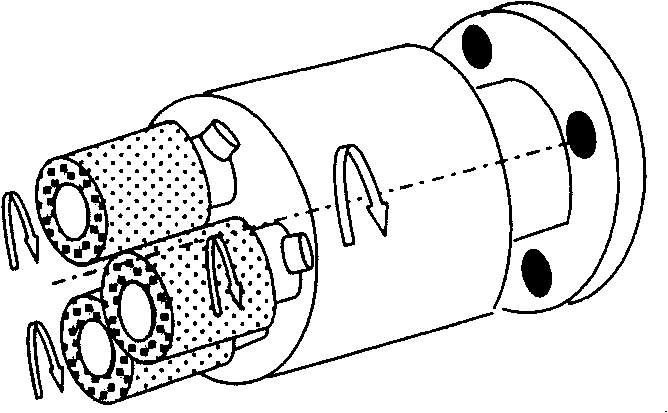

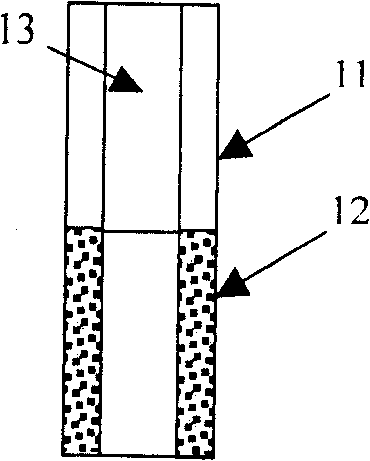

[0020] see figure 1 and figure 2 , This embodiment is composed of a gas transmission device, a pressure cooling pipe 10, a rotatable gas flow divider 2, a grinding head spring ferrule 8 and a rotating housing 5, etc. The gas transmission device is provided with a bearing 3, a shunt air pipeline 4, an air motor 6 and a bearing 7. The spring ferrule 8 of the grinding head is connected with a pressure cooling pipe 10 and a thin-walled cup-shaped diamond grinding head (grinding wheel) 9. The pressure cooling pipe 10 can be Receive high pressure coolant. The rotating part 1 of the machine tool drives the rotating housing 5 to move together, and the bearing 3 is arranged between the inner chamber of the input end of the rotating housing 5 and the rotatable gas distributor 2, and the high-pressure gas drives the rotating shaft of the air motor 6 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com