Enzyme electric coupling catalyzation for treating waste water containing phenol, aromatic amine and azo-dye

An azo dye, aromatic amine technology, applied in chemical instruments and methods, electrochemical water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of poor economic feasibility, high cost, and high treatment cost, and achieve The effect of low oxygen reduction overpotential, many times of use, and high current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

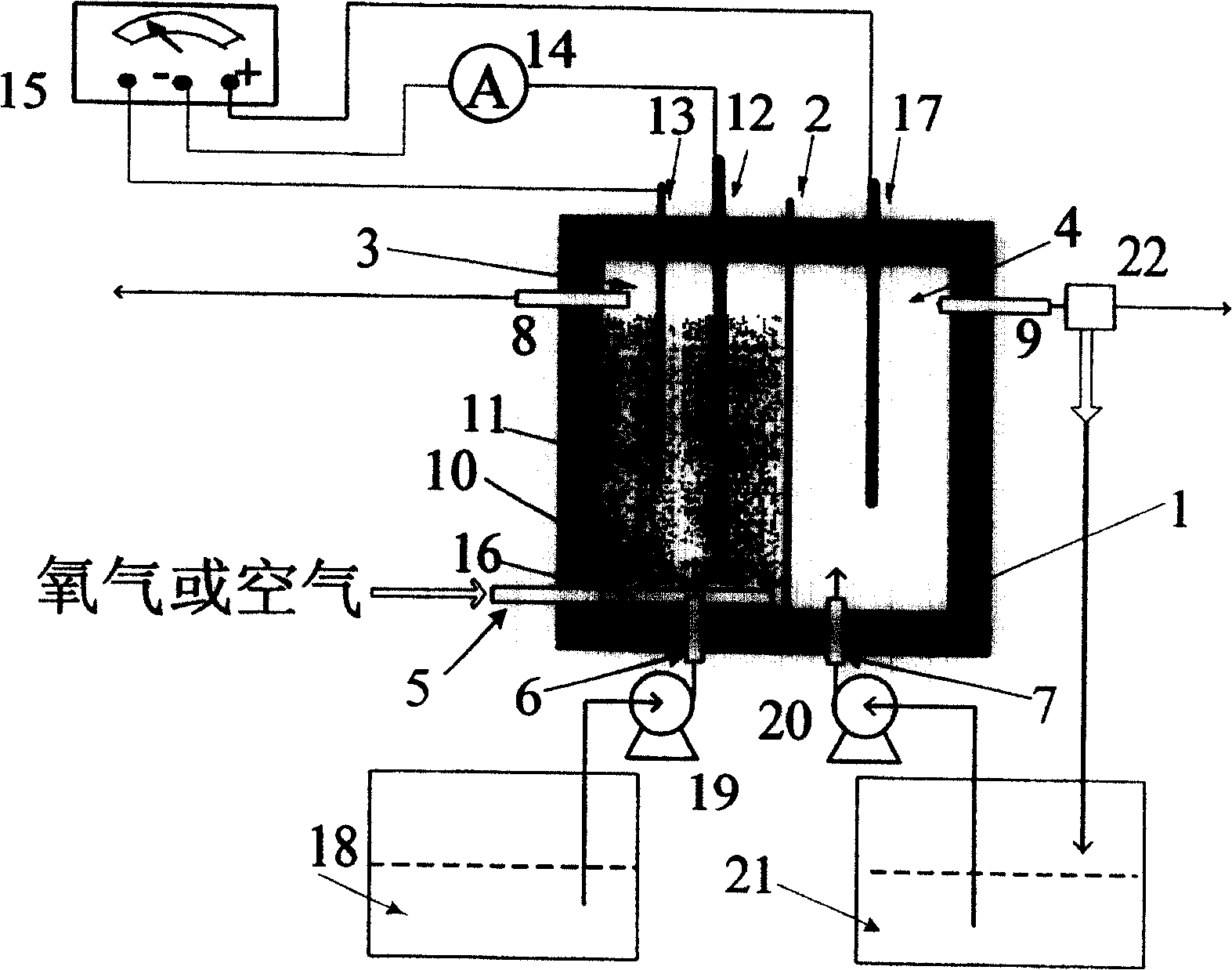

[0023] The pyrolytic graphite block was cut into many cuboids of 4 mm × 5 mm × 5 mm, smoothed on metallographic sandpaper, and used as the base electrode. Add 50 mg of carbon nanotubes with a diameter of 15 to 30 nm into the beaker, and then add 100 mg of dodecyldimethylammonium bromide and 37.5 mL of deionized water. Ultrasonic dispersion was carried out for 10 minutes to obtain a uniformly dispersed and stable suspension. The polished pyrolytic graphite matrix electrode was placed in the carbon nanotube suspension and vibrated in a shaker for 3 hours at a speed of 120 rpm. Take it out and let it dry naturally. Then immerse in 2 mg / mL hemoglobin solution for 2 hours. The cathode I for treating waste water containing phenol, aromatic amine and azo dye is made.

[0024] Fill the negative electrode I into the cathodic chamber of the electrolytic reactor shown in the accompanying drawing as the negative electrode in the form of packing, use a graphite electrode as the anode, a...

Embodiment 2

[0027] The pyrolytic graphite block was cut into many cuboids of 10mm×10mm×10mm, polished smooth on metallographic sandpaper, and used as the substrate electrode. Add 50 mg of multi-walled carbon nanotubes with a diameter of 30-40 nm into the beaker, and then add 25 mg of dihexadecyl phosphate and 150 mL of deionized water. Ultrasonic dispersion was carried out for 20 minutes to obtain a uniformly dispersed and stable suspension. Place the prepared graphite matrix electrode in the suspension of carbon nanotubes and vibrate in a shaker for 1 hour at a speed of 150 rpm. Take it out and let it dry naturally. Then immerse in 1 mg / mL HRP solution for 6 hours. Made into cathode II for treating wastewater containing phenol, aromatic amine and azo dyes.

[0028] Fill the negative electrode II into the cathode chamber of the electrolytic reactor shown in the accompanying drawing as the negative electrode of the packing form, use the graphite electrode as the anode, and the saturated...

Embodiment 3

[0031]The pyrolytic graphite block was cut into many cuboids of 10mm×10mm×5mm, polished smooth on metallographic sandpaper, and used as the base electrode. Add 50 mg of multi-walled carbon nanotubes with a diameter of 5 to 15 nm into a beaker, and then add 50 mg of dioctadecyldimethylammonium bromide and 50 mL of deionized water. Ultrasonic dispersion was carried out for 5 minutes to obtain a uniformly dispersed and stable suspension. The polished graphite matrix electrode was placed in the carbon nanotube suspension and vibrated in a shaker for 6 hours at a speed of 80 rpm. Take it out and let it dry naturally. Immerse again in 10 mg / mL myoglobin solution for 1 hour. Made as cathode III for treating wastewater containing phenols, aromatic amines and azo dyes.

[0032] Fill the negative electrode III into the cathode chamber of the electrolytic reactor shown in the accompanying drawing as the negative electrode in the form of packing, use a graphite electrode as the anode, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com