Soybean protein, process for producing the same and acidic protein foods with use of same

A technology of soybean protein and protein, which is applied in the field of protein food and can solve the problems of unobtainable soybean protein and low yield of soybean protein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

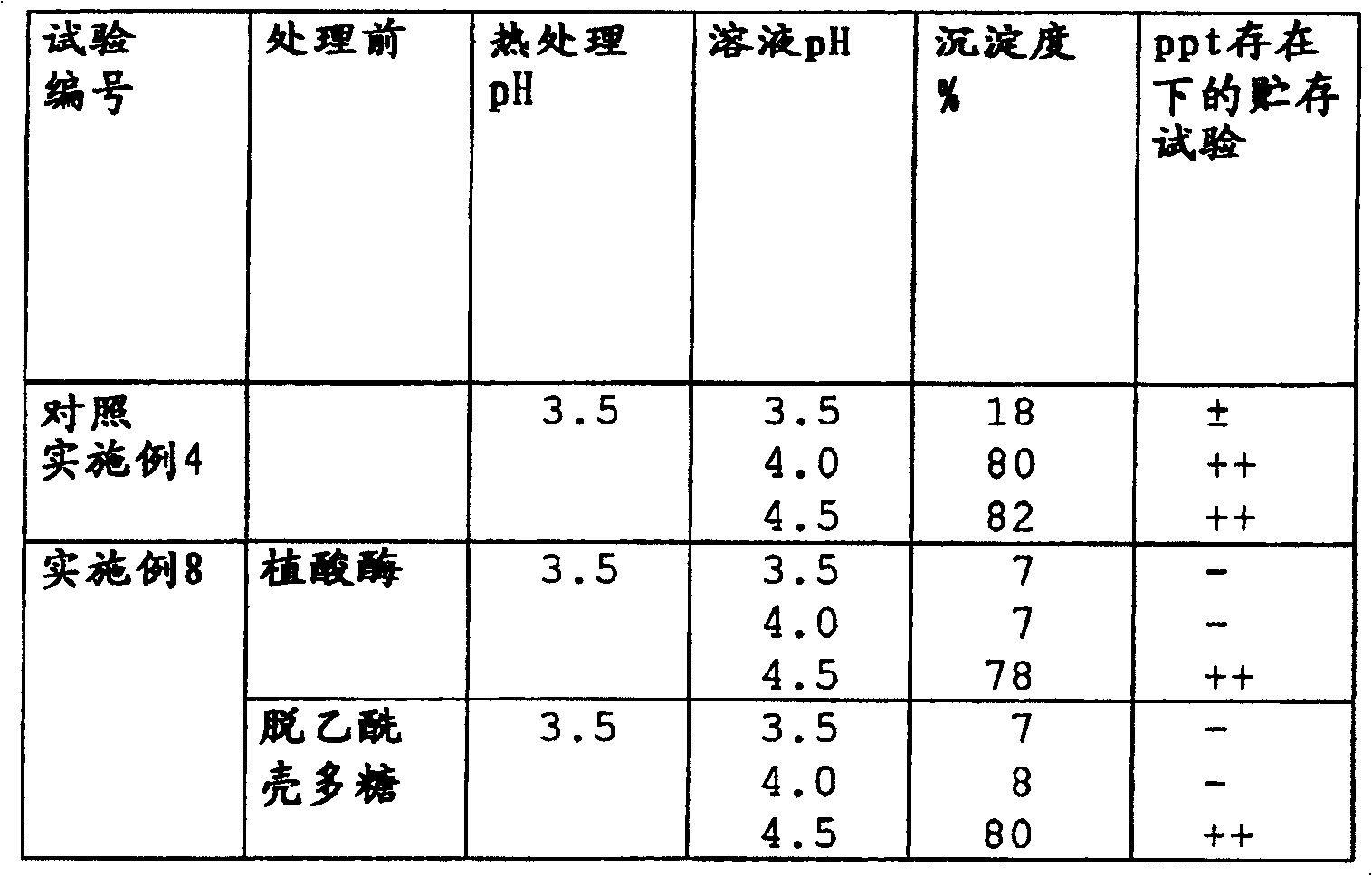

Examples

Embodiment 1

[0047] Embodiment 1

[0048] Soybeans are pressed into chips and their oil is extracted, separated and de-oiled using n-hexane as extraction solvent to obtain defatted soybeans which are less denatured (nitrogen soluble index (NSI) 91). 7 parts of water were added to 1 part by weight of soybeans, the mixture was adjusted to pH 7 with dilute sodium hydroxide solution, and extracted with stirring at room temperature for 1 hour. This mixture was centrifuged at 4,000G, and okara and insoluble matter were separated to obtain defatted soybean milk. Defatted soybean milk was adjusted to pH 4.5 with phosphoric acid and centrifuged at 2,000G in a continuous centrifuge (decanter) to obtain an insoluble fraction (acid precipitated curd) and a Soluble fraction (whey). Water was added to the acid-precipitated curd so that the solids content became 10% by weight to obtain a slurry of the acid-precipitated curd. Adjust to pH 3.5 with phosphoric acid, then heat to about 40°C. To the resu...

Embodiment 1

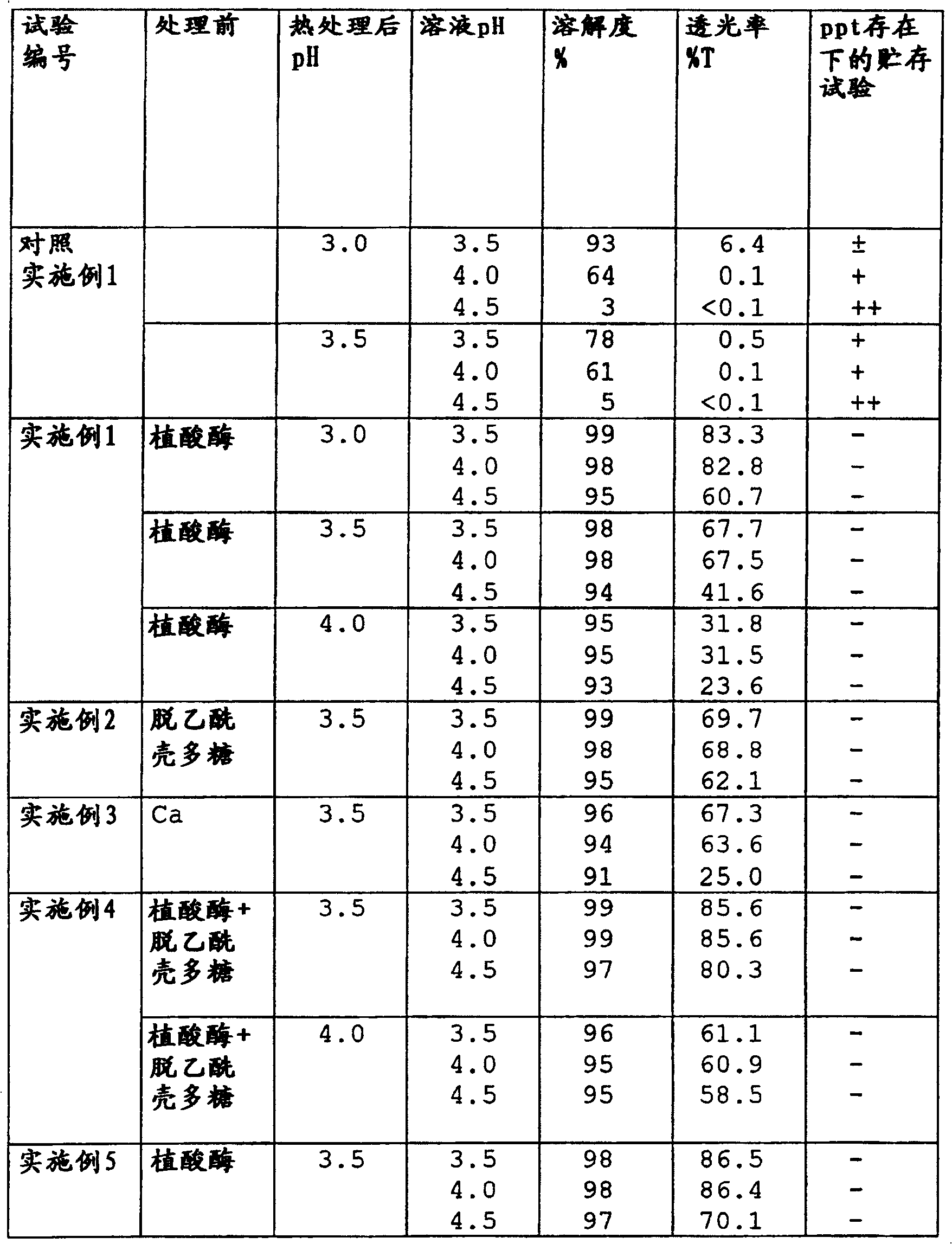

[0050] Comparative Example 1

[0051]The acid-precipitated curd slurry with a solid content of 10% by weight prepared in Example 1 was adjusted to pH 3.0, 3.5 or 4.0 with phosphoric acid. The slurry was then heated at 120°C for 15 seconds using a continuous direct heat sterilizer. Each resultant was spray-dried to obtain a soybean protein powder. However, subsequent spray drying was not performed because the solution adjusted to pH 4.0 formed significant aggregates during heating.

Embodiment 2

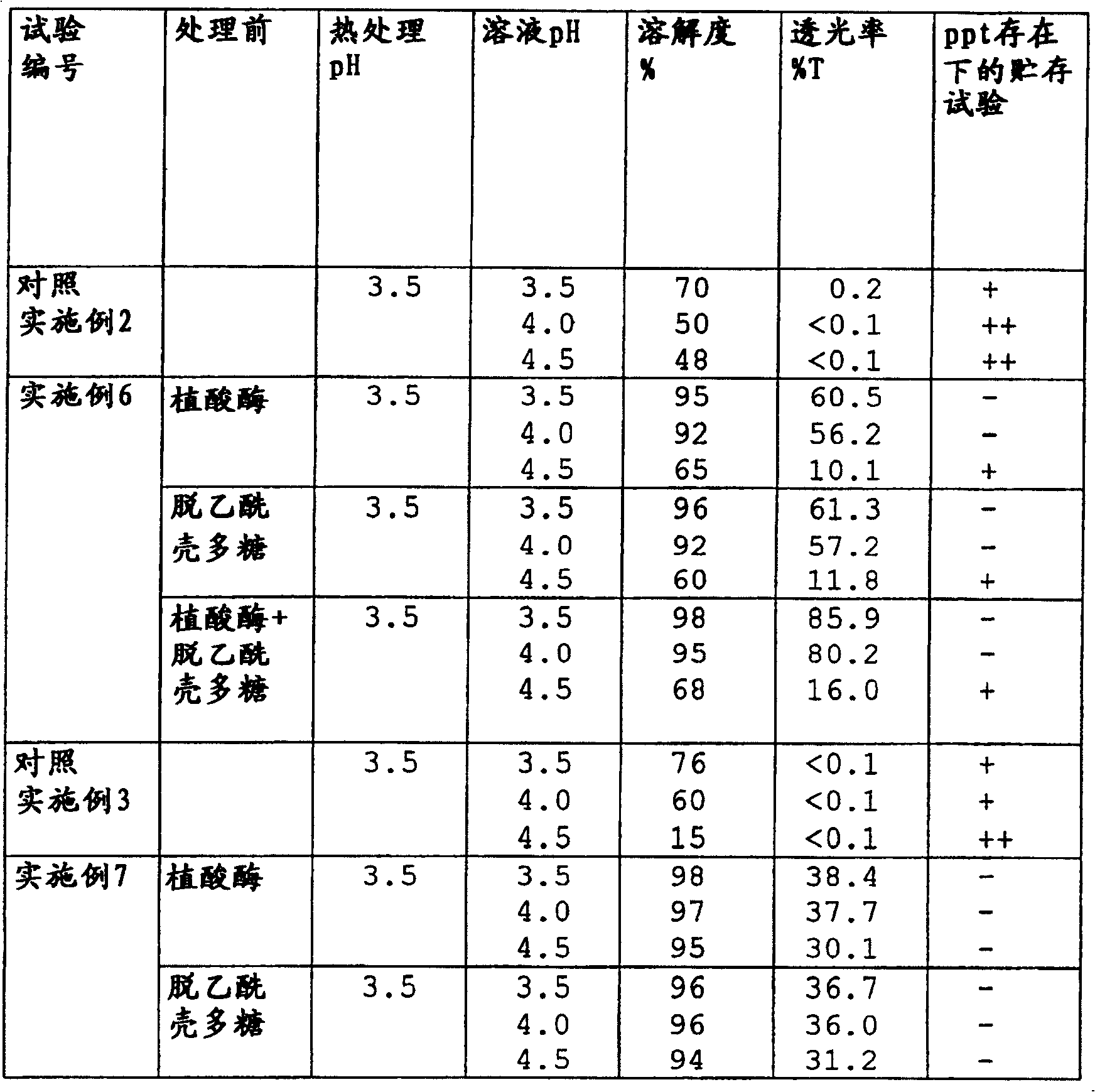

[0052] Embodiment 2 (preparation: add the treatment of chitosan)

[0053] For the acid-precipitated curd slurry with a solid content of 10% by weight prepared in Example 1, the pH was adjusted to 3.5 with phosphoric acid. To the slurry was added chitosan (Chitosan LL, produced by YaezuSuisan Kagaku Kogyo Co.; degree of deacetylation: 80% or more; 1% viscosity: 10 cps (centipoise) or more, in an amount of 5.0% by weight in terms of solid content After sufficiently stirring, the resulting solution was heated at pH 3.0 at 120° C. for 15 seconds using a continuous direct heating sterilizer. It was spray-dried to obtain soybean protein powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com