Amorphous silicon solar cell doubling glass assembly

A technology of solar cells and laminated glass, applied in electrical components, circuits, photovoltaic power generation, etc., can solve problems such as complex process, high cost, and difficult market promotion, and achieve high energy efficiency and large effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

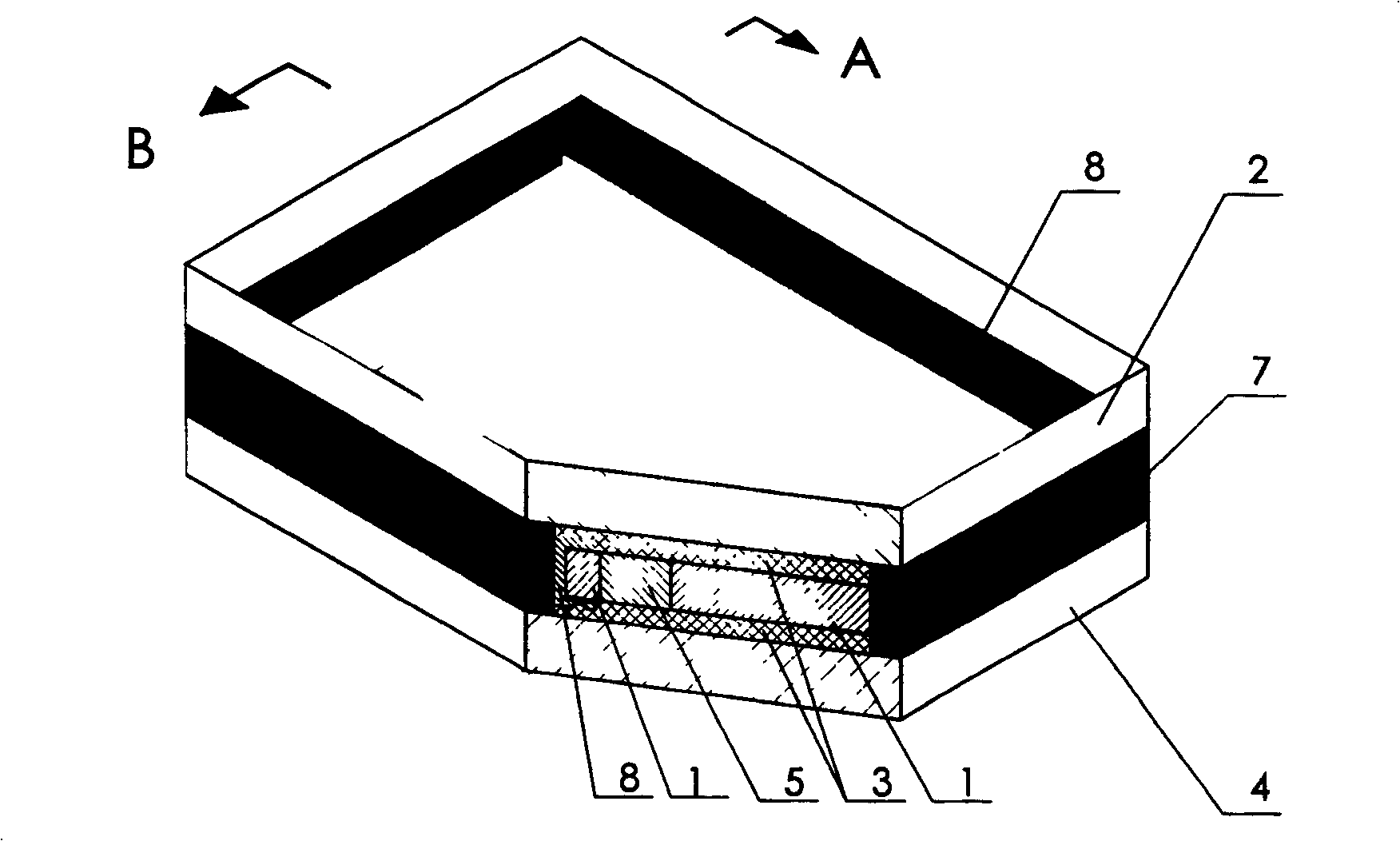

[0052] example 1, Figure 1-5 It is a schematic diagram of the analytical structure of the best embodiment of photovoltaic laminated glass for single-sided amorphous silicon solar cells. The inner layer glass 2 and the outer layer glass 4 adopt common building glass, and the intermediate adhesive film 3 adopts PVB (polyvinyl butyral). Choose to use 35.6×122cm amorphous silicon solar panel, cut into amorphous silicon solar battery strips 1, the length is 122cm, the thickness is 1.5-6.0mm, the width can be cut into different widths according to needs, and the gap between each battery strip 1 It is filled with common architectural glass 5 with the same thickness and length as the battery strip 1, and the width of the glass 5 is determined according to the design width of the gap. The sealant 7 adopts polysulfide glue.

[0053] The intermediate photovoltaic interlayer composed of solar cell strips 1 and glass 5 arranged at intervals leaves a gap of 7mm between the edges of the i...

example 2

[0055] Example 2. Double-sided amorphous silicon solar cell photovoltaic laminated glass is implemented with two single-sided amorphous silicon solar cells. It is used to make double-sided photovoltaic groups, embedded in the conductive frame 8-1, and the light-transmitting gaps with regular intervals are transparent Dielectric 5 fills the cell strips to form a photoelectric interlayer like a grating. Cut the amorphous silicon solar cell panel into long strips, place two amorphous silicon solar cell strips 1 with the back electrodes facing each other, and inlay them in the conductive frame 8, including transparent glass 5, whose thickness and length are the same as those of the battery strips 1, parallel, Arranged in an orderly manner. Taking two sets of battery strips 1 as an example, two sets of positive and negative electrode groups are formed. The positive and negative electrodes of each battery strip 1 are actually in ohmic contact with the convex shape 10-1 of the conduc...

example 3

[0056] Example 3. Two-sided amorphous silicon solar cell photovoltaic laminated glass, using two single-sided amorphous silicon solar cells, using a flexible material as a substrate to make a double-sided photovoltaic group to form a photoelectric interlayer like a grating , cut the flexible amorphous silicon solar panel into long strips, and inlay two amorphous silicon solar battery strips 1 with the two backlight faces facing each other in the conductive frame 8-1, and the positive and negative electrodes of the battery strips are distributed in the T-shaped conductive frame In 8-1, make ohmic contact with the 10-1 frame with up and down convex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com