Bottoms combustion air preheater system and method of ethylene cracking furnace

An ethylene cracking furnace and air preheating technology, which is applied in combustion methods, lighting and heating equipment, indirect carbon dioxide emission reduction, etc., can solve the problems of large operating flexibility and lax system working parameters, so as to reduce power consumption and save fuel Ease of consumption, use, maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

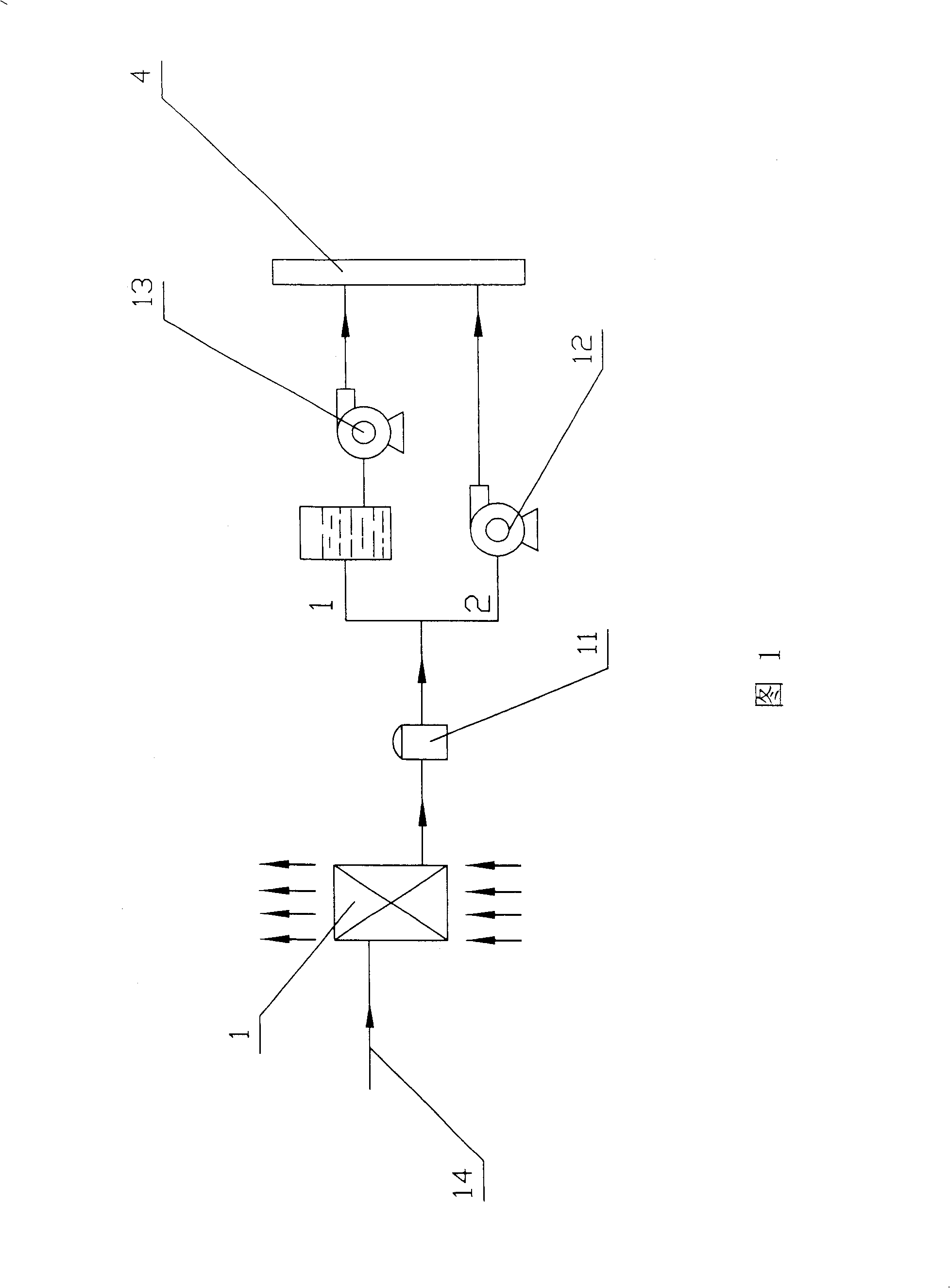

[0029] Shown in Fig. 1, a kind of ethylene cracking furnace bottom burner air preheating system and method, mainly by preheater 1, steam trap 11, drain pump 12 or centrifugal pump 13 form, its method comprises the following steps:

[0030] 1. Introduce the balanced low-pressure vent steam 14 in the plant area into the preheater 1, and the preheater 1 works under negative pressure working conditions. Using the negative pressure margin of the cracking furnace furnace, the ambient cold air is sucked into the preheater 1, After turning into hot air, it enters the burner and then enters the furnace;

[0031] 2. After the low-pressure venting steam passes through the preheater 1 with a certain area and the steam trap 11 matching the design of the preheater, the flow rate of the low-pressure venting steam can be automatically adjusted according to the change of the ambient temperature;

[0032] 3. After the steam turns into condensate, the internal energy of the steam’s own pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com