Recovery method of trifluoromethane

A technology of trifluoromethane and difluorochloromethane, which is applied in the recovery of trifluoromethane and the field of trifluoromethane, can solve the problems of ozone layer destruction, environmental pollution, high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

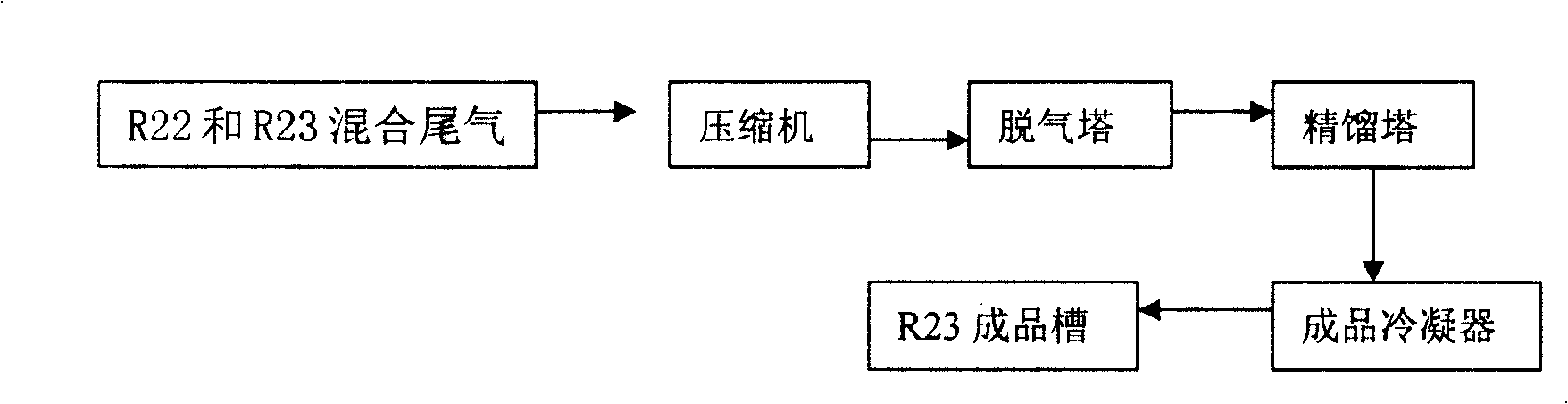

Embodiment 1

[0031] The exhaust gas (composed of difluorochloromethane: trifluoromethane = 65: 35 (weight ratio)) from the exhaust tower of the difluorochloromethane plant first enters the degassing tower after being compressed by the compressor, and the degassing tower The temperature is 25°C and the pressure is 3.5MPa. , to separate difluorochloromethane and trifluoromethane; then the separated crude trifluoromethane enters the rectification tower, the temperature of the rectification tower is 25° C., and the pressure is 3.5 MPa. Trifluoromethane with a purity of >99.5% is obtained. At the same time, difluorochloromethane with a purity of ≥95% was recovered. The trifluoromethane product from the top of the rectification tower is cooled and liquefied by the product condenser, and then collected in the trifluoromethane product tank. The condensing temperature of the finished condenser is 0°C, and the condensing pressure is 3.5MPa.

Embodiment 2

[0033] The exhaust gas (composed of difluorochloromethane: trifluoromethane = 65: 35 (weight ratio)) from the exhaust tower of the difluorochloromethane plant first enters the degassing tower after being compressed by the compressor, and the degassing tower The temperature is 30°C and the pressure is 4.5MPa. , to separate difluorochloromethane and trifluoromethane; then the separated crude trifluoromethane enters the rectification tower, the temperature of the rectification tower is 20°C, and the pressure is 3.5MPa. Trifluoromethane with a purity of >99.5% is obtained. At the same time, difluorochloromethane with a purity of ≥95% was recovered. The trifluoromethane product from the top of the rectification tower is cooled and liquefied by the product condenser, and then collected in the trifluoromethane product tank. The condensing temperature of the finished condenser is -10°C, and the condensing pressure is 4.5MPa.

Embodiment 3

[0035] The exhaust gas (composed of difluorochloromethane: trifluoromethane = 65: 35 (weight ratio)) from the exhaust tower of the difluorochloromethane plant first enters the degassing tower after being compressed by the compressor, and the degassing tower The temperature is 40°C and the pressure is 4.5MPa. , to separate difluorochloromethane and trifluoromethane; then the separated crude trifluoromethane enters the rectification tower, the temperature of the rectification tower is 20°C, and the pressure is 3.5MPa. Trifluoromethane with a purity of >99.5% is obtained. At the same time, difluorochloromethane with a purity of ≥95% was recovered. The trifluoromethane product from the top of the rectification tower is cooled and liquefied by the product condenser, and then collected in the trifluoromethane product tank. The condensing temperature of the finished condenser is -10°C, and the condensing pressure is 4.5MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com