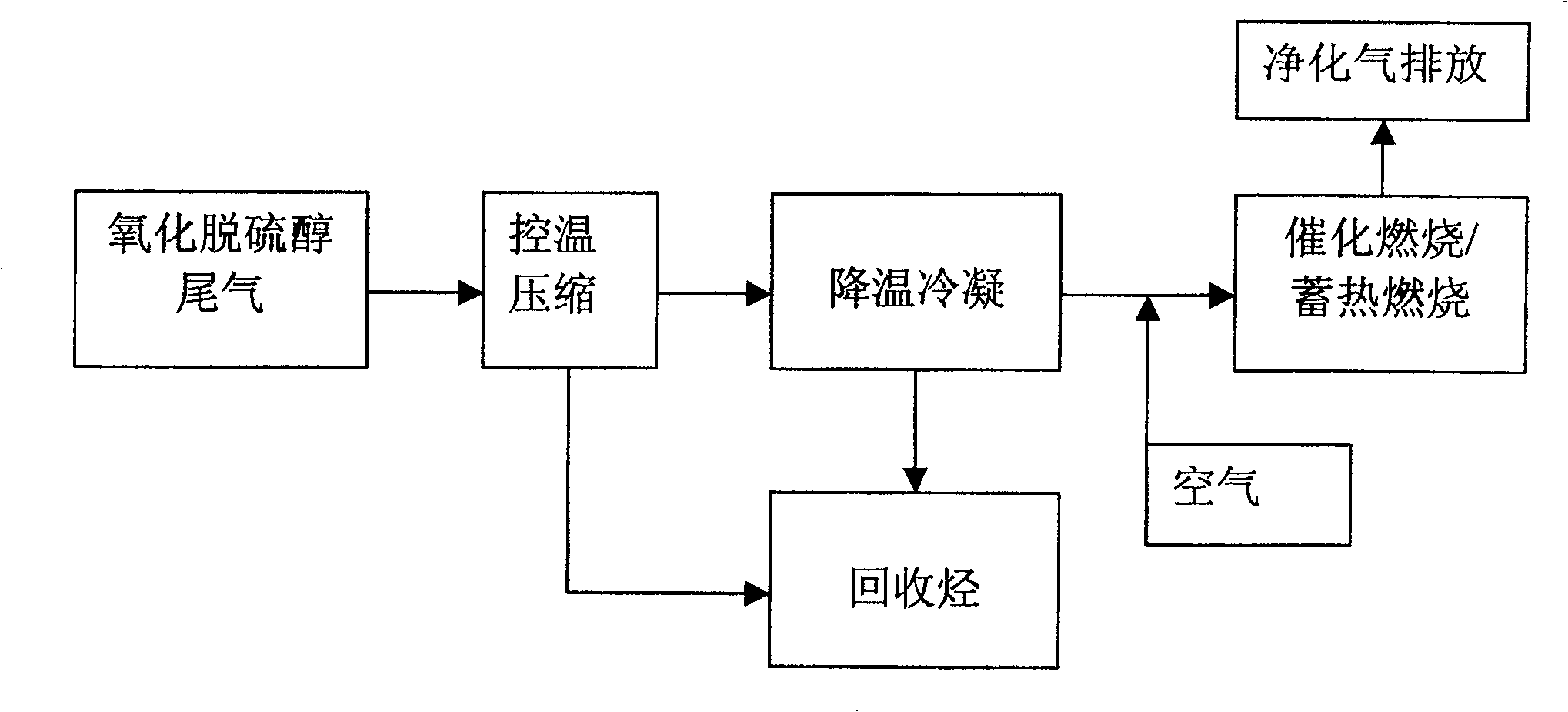

Method for processing light hydrocarbon oxidation sweetening tail gas

A technology for oxidative sweetening of mercaptans and light hydrocarbons, applied in chemical instruments and methods, separation methods, steam condensation, etc., can solve problems such as industrial application limitations, increased operating costs, and poor comprehensive economy, and achieve equipment investment and operating costs Low cost, easy operation and high degree of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

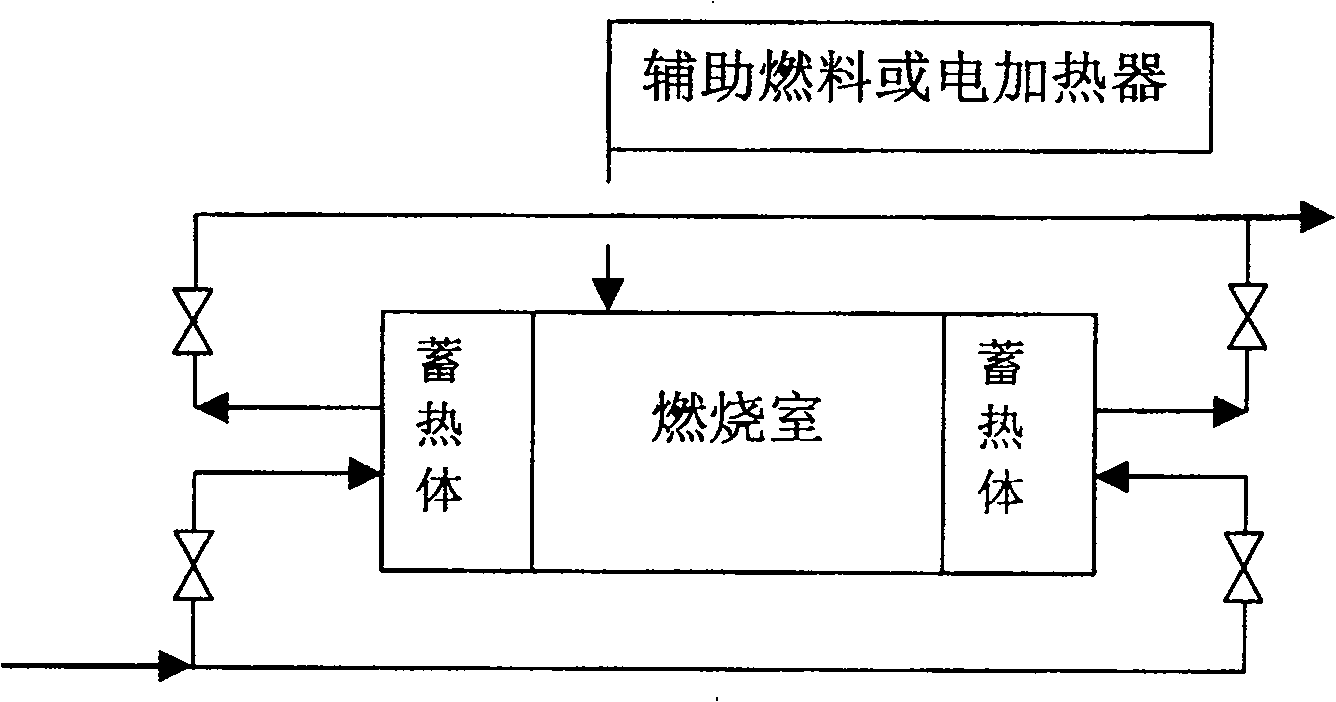

Embodiment 1

[0022] Gasoline air oxidation sweetening tail gas of an enterprise contains 32v% hydrocarbons, the tail gas temperature is 53°C, and the oxygen content is 17v%. First compress the tail gas to 2.0MPa, then use the enterprise's circulating cooling water to cool down to 40°C, and recover condensed hydrocarbons, then condense and cool the tail gas to -10°C, single-stage compression refrigeration, recover oily condensate, and condensate The hydrocarbon content of the tail gas is 8.9v%, and the hydrocarbon recovery rate is over 60v%. After exchanging heat between the condensed tail gas and the pre-condensed gas, use air to adjust the total hydrocarbon concentration to 3000-8000 μL / L (calculated as methane), and use regenerative combustion to purify the gas. The total hydrocarbon concentration of the purified gas is less than 120 μL / L (calculated as methane). In line with national emission standards. regenerative combustion image 3 Operation mode, the regenerator is a diameter cer...

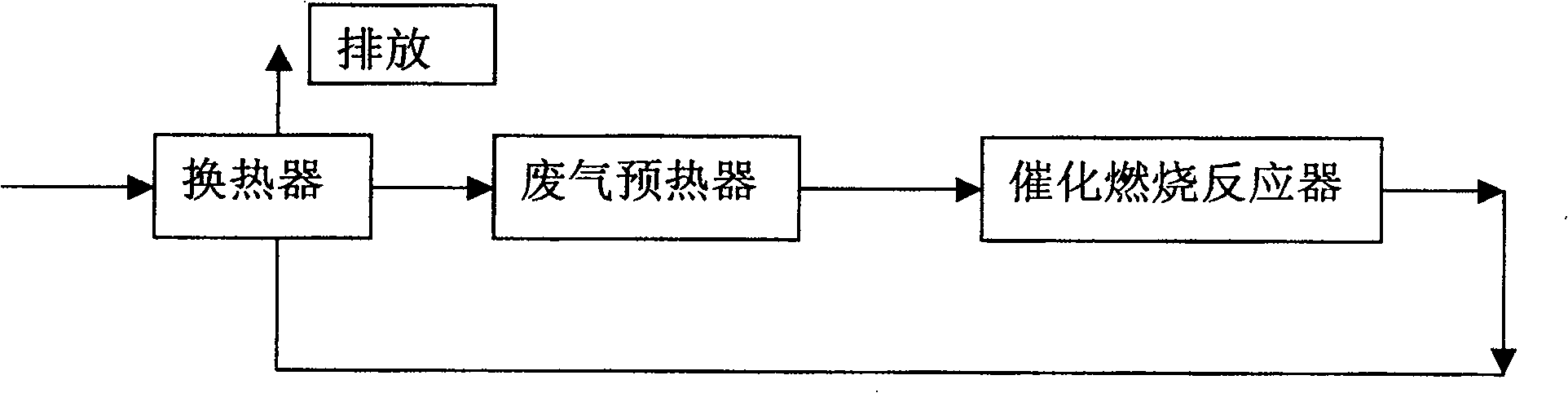

Embodiment 2

[0024] Gasoline sweetening tail gas by air oxidation in an enterprise contains 25v% hydrocarbons, tail gas temperature is 45°C, and oxygen content is 16v%. First compress the exhaust gas to 0.8MPa, then use the enterprise's circulating cooling water to cool down to 40°C, and recover condensed hydrocarbons, then condense and cool the tail gas to -40°C, use two-stage compression refrigeration, recover oily condensate, and condensate The tail gas hydrocarbon content is 4.1v%, and the hydrocarbon recovery rate is over 80v%. After exchanging heat between the condensed tail gas and the pre-condensed gas, use air to adjust the total hydrocarbon concentration to 3000-8000 μL / L (calculated as methane), and use catalytic combustion to purify it. National emission standards. Catalytic combustion adopts figure 2 Operation mode, the catalytic combustion catalyst is a honeycomb catalyst containing Pt 0.26wt%, Pd 0.13wt%, the inlet temperature of the catalytic combustion catalyst bed is a...

Embodiment 3

[0026] Gasoline air oxidation sweetening tail gas of an enterprise contains 30v% hydrocarbons, tail gas temperature is 50°C, and oxygen content is 17v%. First compress the tail gas to 1.2MPa, then use the enterprise's circulating cooling water to cool down to 42°C, and recover condensed hydrocarbons, then condense and cool the tail gas to -35°C, use two-stage compression refrigeration, recover oily condensate, and condensate The hydrocarbon content of the tail gas is 3.2v%, and the hydrocarbon recovery rate is over 85v%. After exchanging heat between the condensed tail gas and the pre-condensed gas, use air to adjust the total hydrocarbon concentration to 3000-8000 μL / L (calculated as methane), and use catalytic combustion to purify it. National emission standards. Catalytic combustion adopts figure 2 Operation mode, the catalytic combustion catalyst is a spherical alumina carrier catalyst with a diameter of 4mm containing Pt 0.05wt% and Pd 0.02wt%, the inlet temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com