Coagulating removing method of calcium sulfate fouling in reverse osmosis concentrated liquid

A technology of reverse osmosis concentrate and calcium sulfate, which is applied in the directions of osmosis/dialysis water/sewage treatment, flocculation/sedimentation water/sewage treatment, complex/solubilizer treatment, etc., and can solve problems such as scaling and unusability. Achieve low cost, improve recovery rate, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

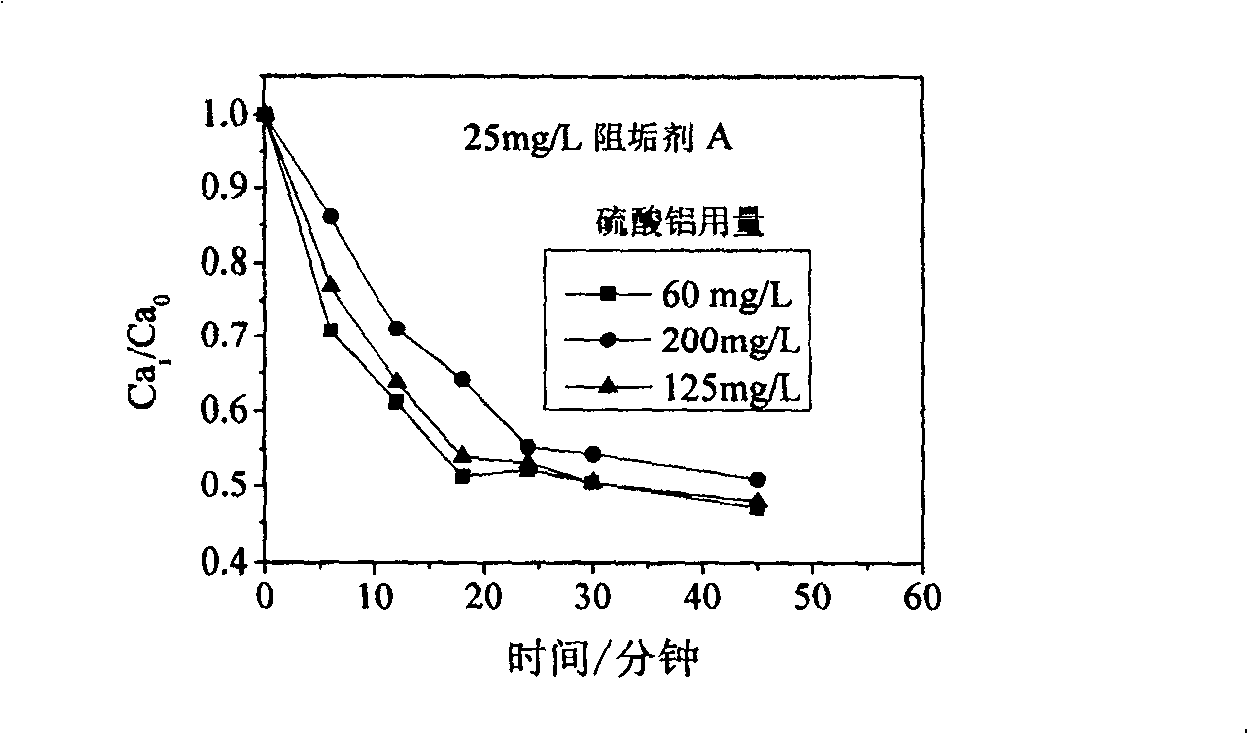

[0017] Simulate the composition of a reverse osmosis concentrate to configure the solution, weigh NaCl, Na 2 SO 4 , CaCl 2 Add distilled water and mix, put into 1L beaker, and add 25mg / L commercial antiscalant A (the product LB2000 of Shandong Zibo Libang Fine Chemical Co., Ltd.), make 800ml concentrated liquid, wherein Ca 2+ =3250mg / L, SO 4 2- =6300mg / L, Na + =6007mg / L, Cl - =10352 mg / L. The temperature of the concentrate is 30°C, and its initial saturation index SI is 4.4.

[0018] Then add 60 mg / L aluminum sulfate for coagulation, carry out coagulation for half a minute at 300 rpm, and then coagulate for 40 minutes at 50 rpm. During the coagulation reaction, the calcium ion concentration of the solution was measured at regular intervals. Then the calcium ion concentration is normalized, that is, the measured calcium ion concentration Ca 1 are divided by the initial calcium ion concentration Ca 0 , then make Ca 1 / Ca 0 Variation curve over time.

[0019] Change ...

Embodiment 2

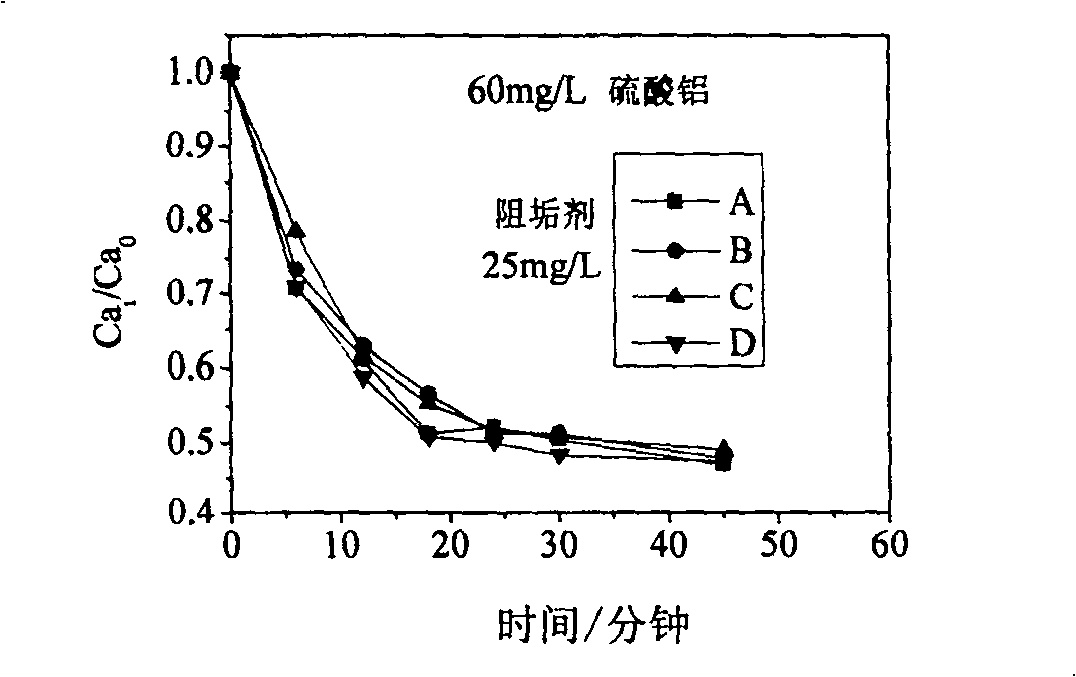

[0023] In this example, the type of scale inhibitor was changed to commercial scale inhibitor B (the product LB0100 of Shandong Zibo Libang Fine Chemical Co., Ltd.) for experimentation.

[0024] Simulate the composition of a reverse osmosis concentrate to configure the solution, weigh NaCl, Na 2 SO 4 , CaCl 2 Add distilled water to mix, put it into a 1L beaker, and add 25mg / L commercial antiscalant B to make 800ml concentrated solution, in which Ca 2+ =3250mg / L, SO 4 2- =6300mg / L, Na + =6007mg / L, Cl - =10352 mg / L. The temperature of the concentrate is 30°C, and its initial saturation index SI is 4.4.

[0025] Then add 60 mg / L aluminum sulfate for coagulation, carry out coagulation for half a minute at 300 rpm, and then coagulate for 40 minutes at 50 rpm. During the coagulation reaction, the calcium ion concentration of the solution was measured at regular intervals. Then the calcium ion concentration is normalized, that is, the measured calcium ion concentration Ca 1...

Embodiment 3

[0029] In this example, the type of scale inhibitor was changed to commercial scale inhibitor C (chemical sodium hexametaphosphate) for experimentation.

[0030] Simulate the composition of a reverse osmosis concentrate to configure the solution, weigh NaCl, Na 2 SO 4 , CaCl 2 Add distilled water and mix, put it into a 1L beaker, add 25mg / L commercial antiscalant C to make 800ml concentrated solution, in which Ca 2+=3250mg / L, SO 4 2- =6300mg / L, Na + =6007mg / L, Cl - =10352 mg / L. The temperature of the concentrate is 30°C, and its initial saturation index SI is 4.4.

[0031] Then add 60 mg / L aluminum sulfate for coagulation, carry out coagulation for half a minute at 300 rpm, and then coagulate for 40 minutes at 50 rpm. During the coagulation reaction, the calcium ion concentration of the solution was measured at regular intervals. Then the calcium ion concentration is normalized, that is, the measured calcium ion concentration Ca 1 are divided by the initial calcium i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com