Vacuum spray drying method for liquid material and vacuum continuous spray drying machine

A vacuum spray drying and spray drying machine technology, which is applied in the direction of non-progressive dryers, drying machines, drying solid materials, etc., can solve the problems of material instability, high energy consumption, and high temperature, and achieve low temperature and low energy consumption. Low, little pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

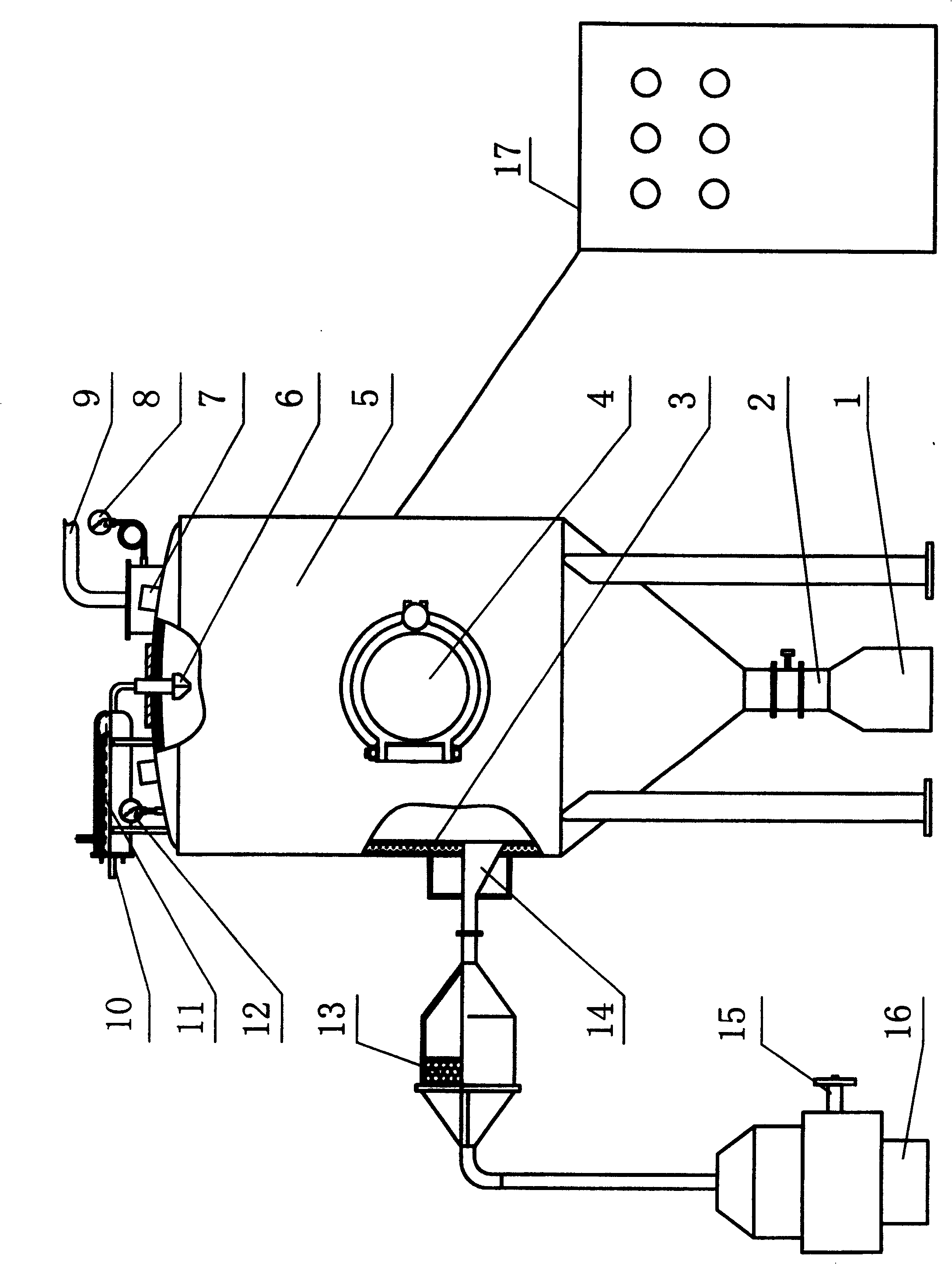

Image

Examples

Embodiment 1

[0021] Embodiment one: the situation that " lactose solution " is dried, its data are as follows:

[0022] Lactose solution: 8% lactose; 92% water

[0023] Tank temperature: 40~60℃ Vacuum degree: 40KPa~80KPa

[0024] Material preheating temperature: 40~60℃

[0025] Moisture content of final dry "lactose" powder: 6%

[0026] Effect: Improve production efficiency (while the conventional centrifugal spray drying method is easy to gelatinize and cannot be dried)

Embodiment 2

[0027] Embodiment two: The situation that " acetylglutamine for injection " is dried, its data are as follows:

[0028] Aseptic treatment of "Aceglutamine for Injection" solution: filter and sterilize with a 0.2μ microporous membrane to make a sterile solution, and the water content of the material is 74.2%;

[0029] Tanks and pipelines are cleaned and sterilized;

[0030] Temperature inside the drying tank: 35~50℃ Vacuum degree: 40KPa~80KPa

[0031] Material preheating temperature: 35~50℃

[0032] The final water content of "Aceglutamine for Injection" sterile powder: 4%.

[0033] Effect: Improve production efficiency. It takes 55 hours to freeze-dry a batch, but it only takes 5 hours to use vacuum continuous spray drying method, which improves production efficiency by 10 times.

Embodiment 3

[0034] Embodiment three: the situation that " compound Chinese medicine hypoglycemic king " aqueous extract is dried, its data are as follows:

[0035] Compound Chinese medicine hypoglycemic aqua regia extract:

[0036] Density: 1.15~1.35g / cm 3 ; Moisture content: 38%

[0037] Temperature inside the tank: 50~80℃; Vacuum degree: 30KPa~60KPa;

[0038] Material preheating temperature: 50~80℃;

[0039] Final moisture content: 3%.

[0040] Effect: Improve production efficiency ≥ 2 times;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com