Air cooled water composite cooling tower

A cooling tower and composite technology, which is applied in the field of air-cooled and cold-water composite cooling towers, can solve the problems of low cooling efficiency, high cost of air coolers, and small specific heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

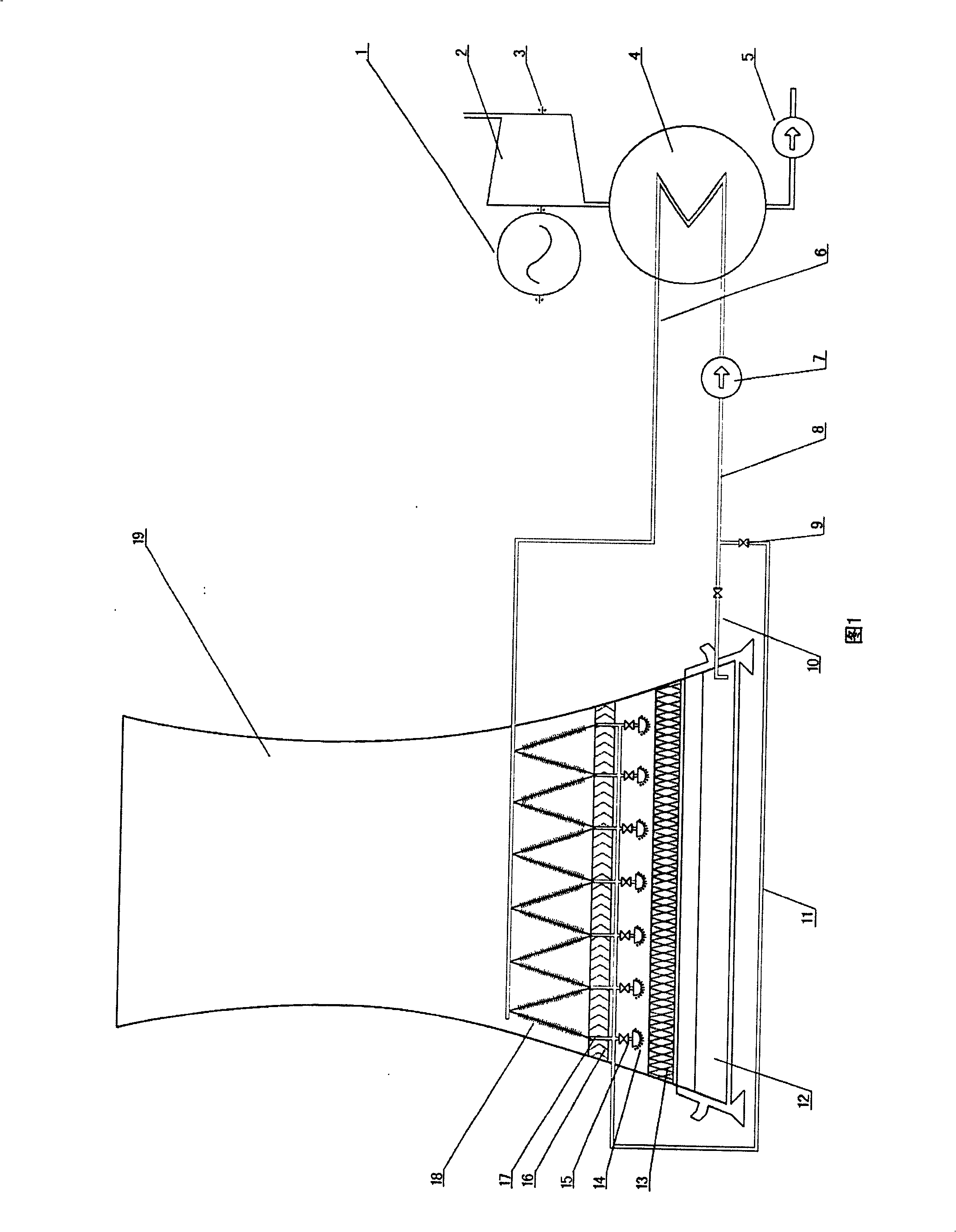

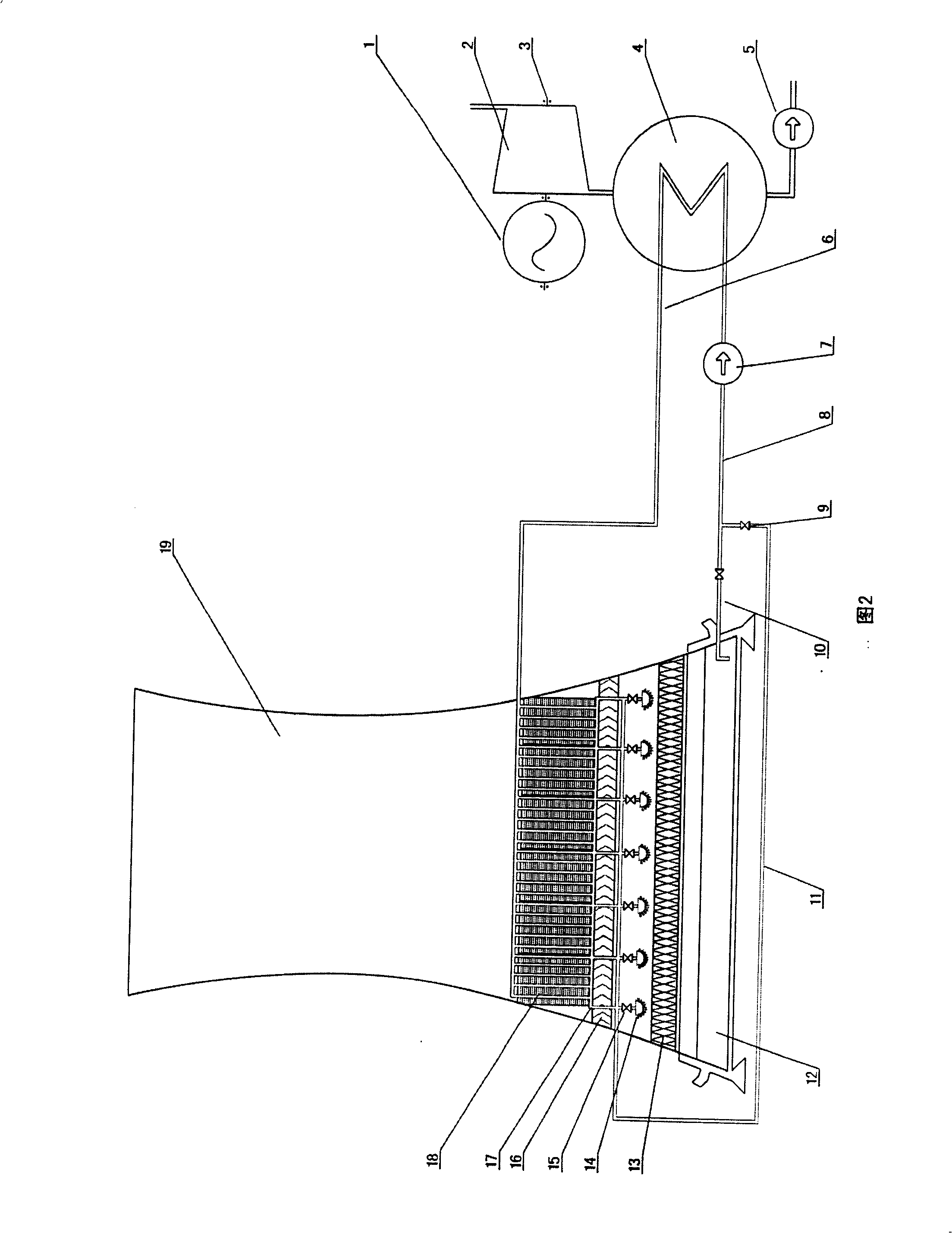

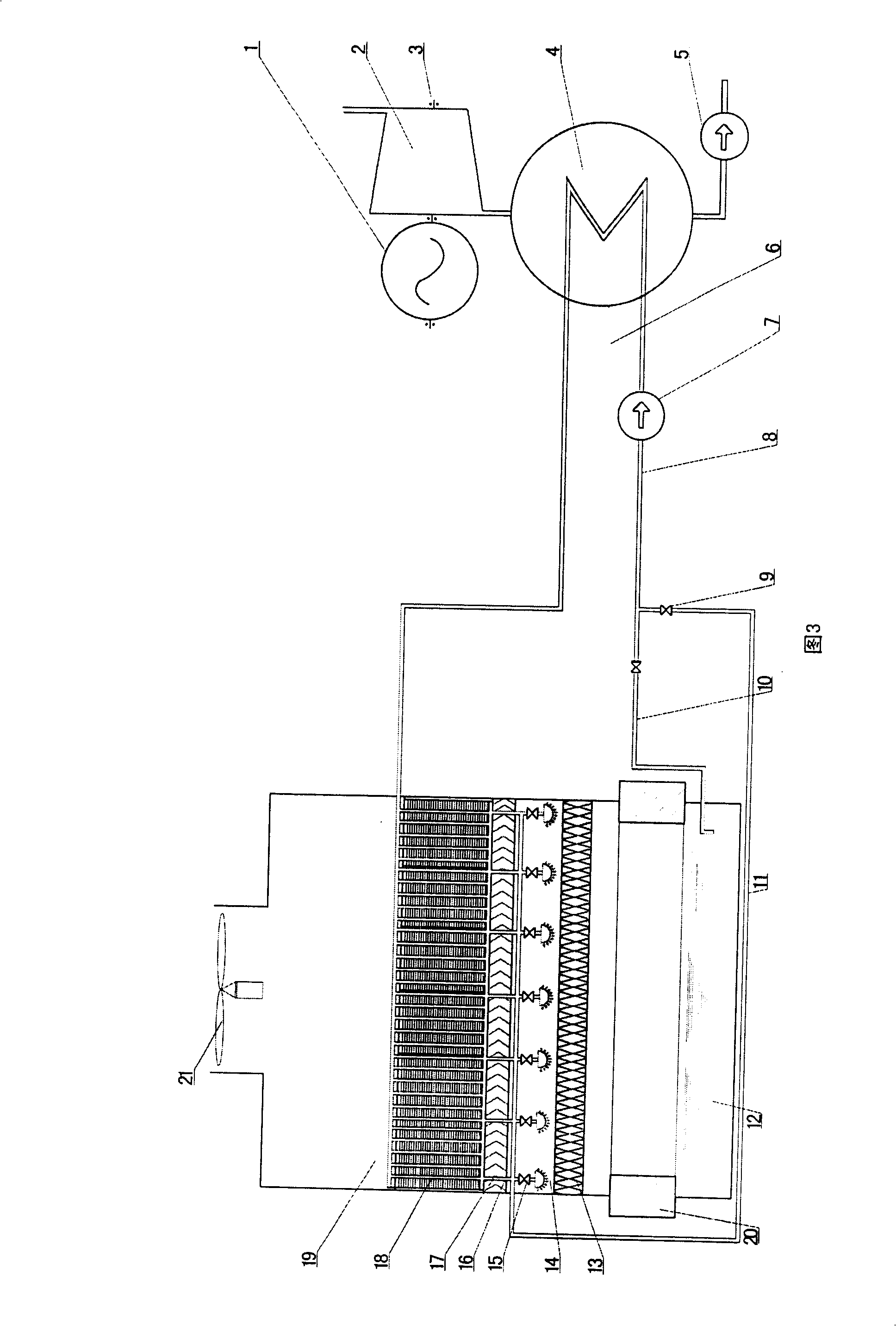

[0016] As shown in Figure 1: on the air cooler bracket 17 arranged in the wind direction under the honeycomb wave water distribution cooling layer 13 and the water distributor 14 in the cooling tower fan duct 19, an air cooler 18 arranged in a herringbone shape is installed. The mounting bracket 17 of the arranged air cooler 18 is fixed on the load-bearing support body of the cooling tower. The hot circulating water to be cooled enters the cooling tower air duct 19 through the hot circulating water delivery main pipe 6, and is respectively connected with the water inlets on the air cooler 18 arranged in a herringbone shape, and is uniformly distributed through the water distribution pipes with equal flow paths and equal pressures. The water is distributed in the air cooler 18 arranged in a herringbone shape. The hot water cooled by the air cooler is collected through the water collection pipe 11 at the end of the air cooler, and the water is distributed in the honeycomb by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com