Substrate-placing platform, substrate processing device and production method of substrate-placing platform

A technology of substrate processing device and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, ion implantation plating, gaseous chemical plating, etc., can solve the problems such as the method of processing the surface of the platform base that is not shown, and prevent uneven etching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

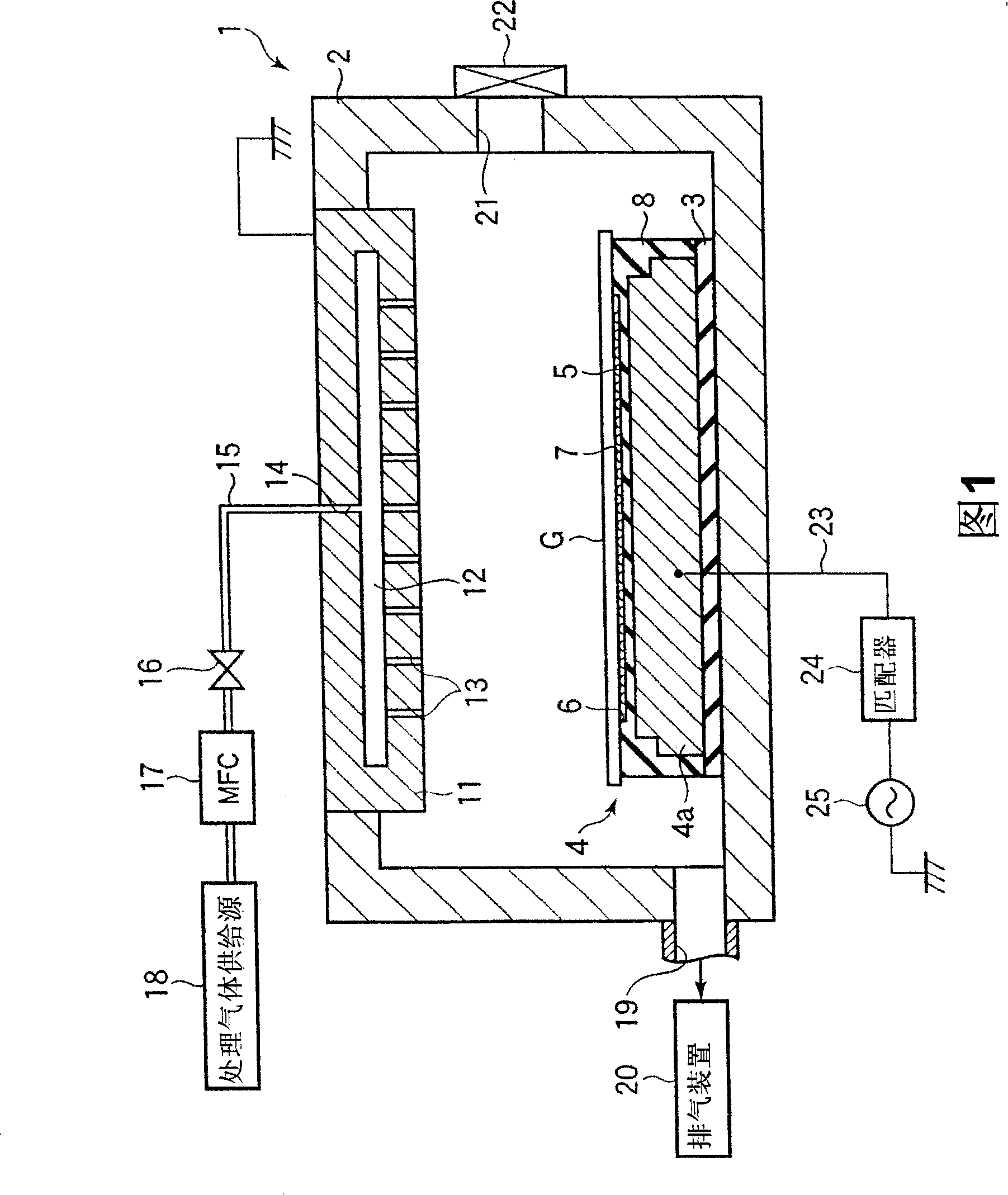

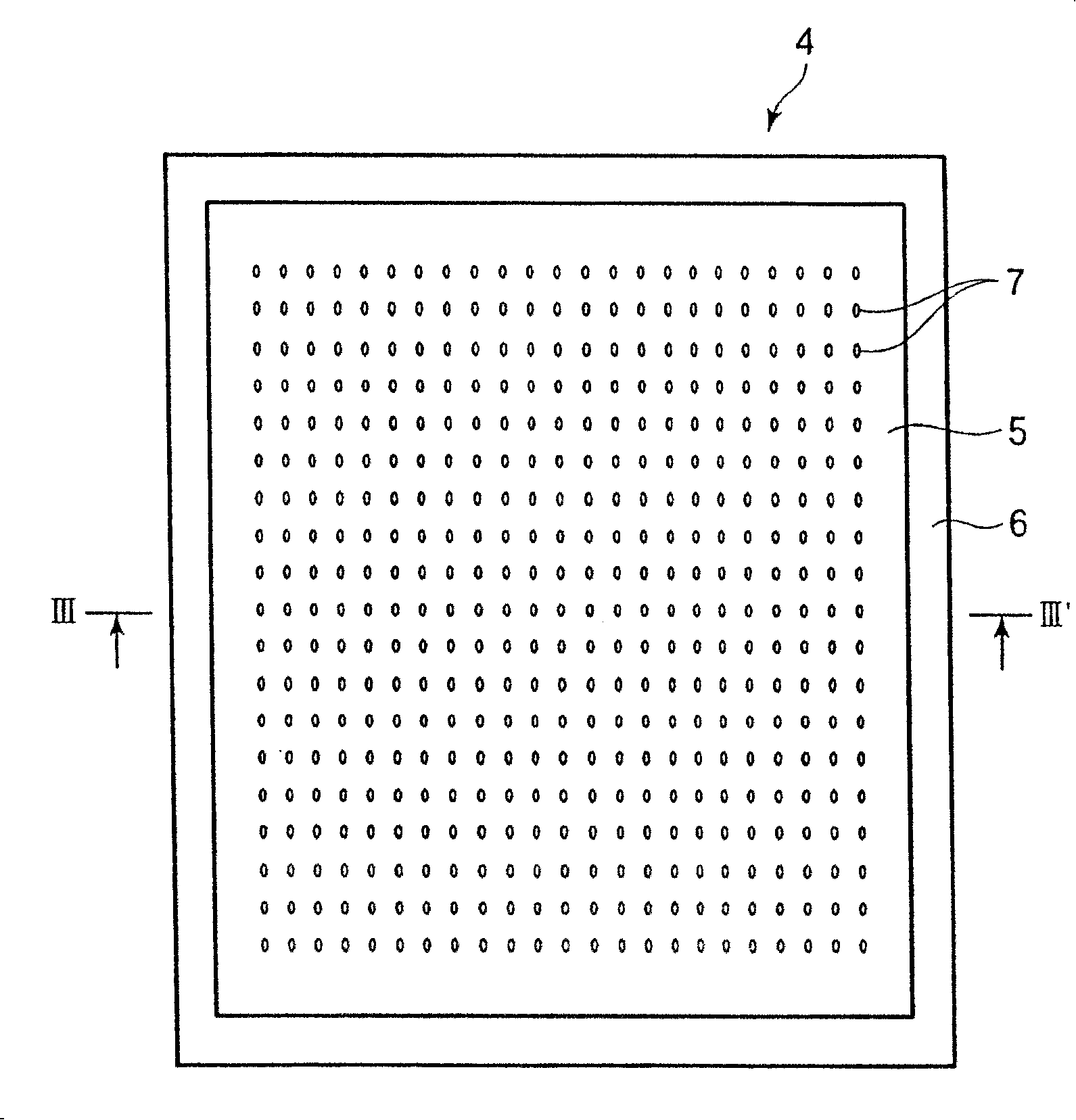

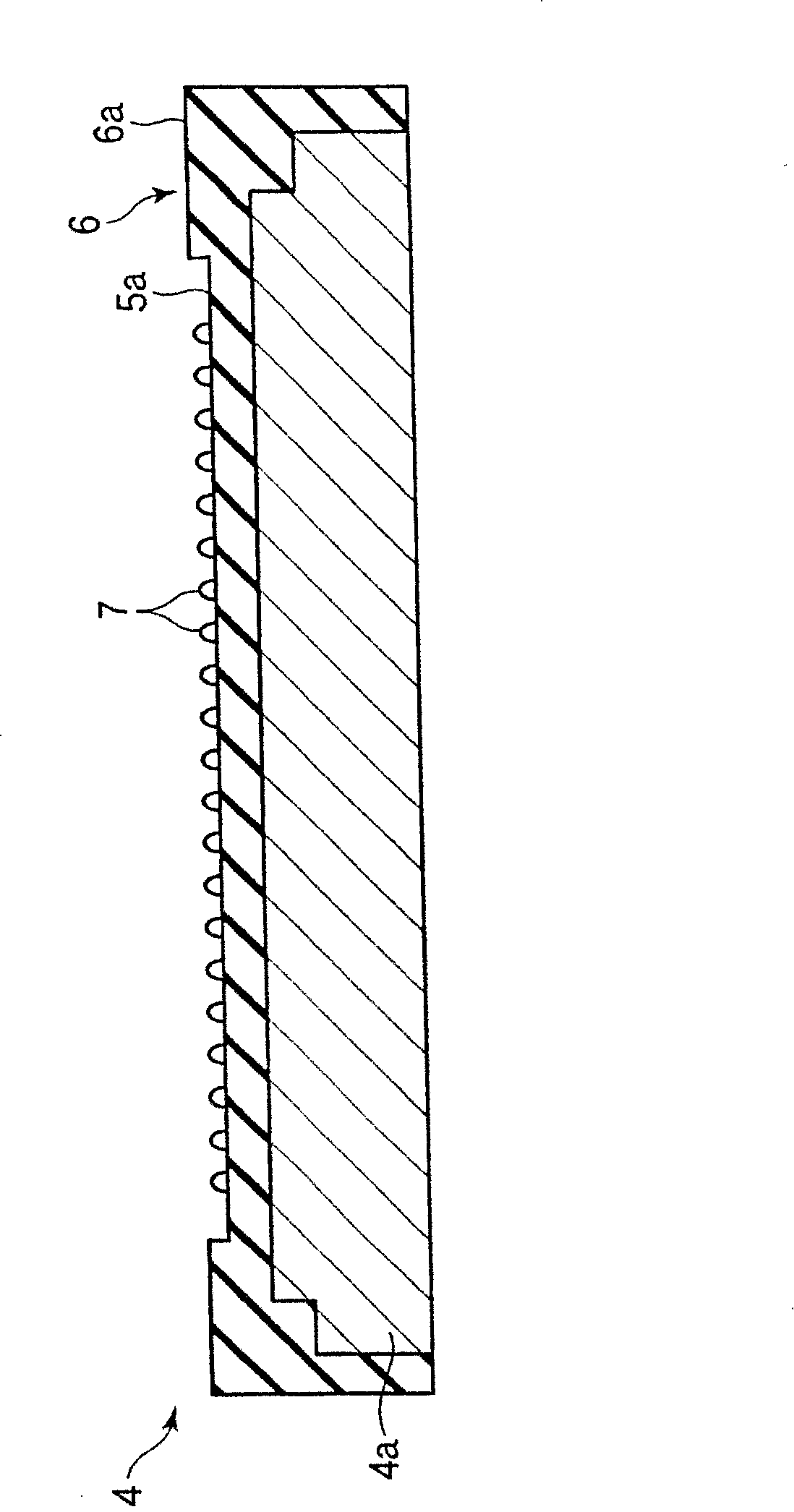

[0091] Next, preferred embodiments of the present invention will be described with reference to the drawings. 1 is a cross-sectional view showing a plasma etching apparatus as an example of a processing apparatus provided with a susceptor as a substrate mounting table according to an embodiment of the present invention. This plasma etching apparatus 1 is a cross-sectional view of an apparatus for performing predetermined processing of the glass substrate G for FPD, and is configured as a capacitively coupled parallel plate plasma etching apparatus. Here, examples of the FPD include a liquid crystal display (LCD), a light emitting diode (LED) display, an electroluminescence (Electro Luminescence; EL) display, a fluorescent display tube (Vacuum Fluorescenl Display; VFD), a plasma display panel (PDP), and the like. . In addition, the processing apparatus of this invention is not limited to a plasma etching apparatus.

[0092] This plasma etching apparatus 1 has a rectangular cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com