Method for producing thallus protein forage by using solid state fermentation of pomace and dreg or stalks with mixed aerobic bacteria liquor

A technology of protein feed and solid-state fermentation, which is applied in animal feed, animal feed, protein food processing, etc., can solve the problems of small number of product cells, high energy consumption, complicated operation, etc., achieve high bacterial cell concentration, save equipment and Energy, effect of improving nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

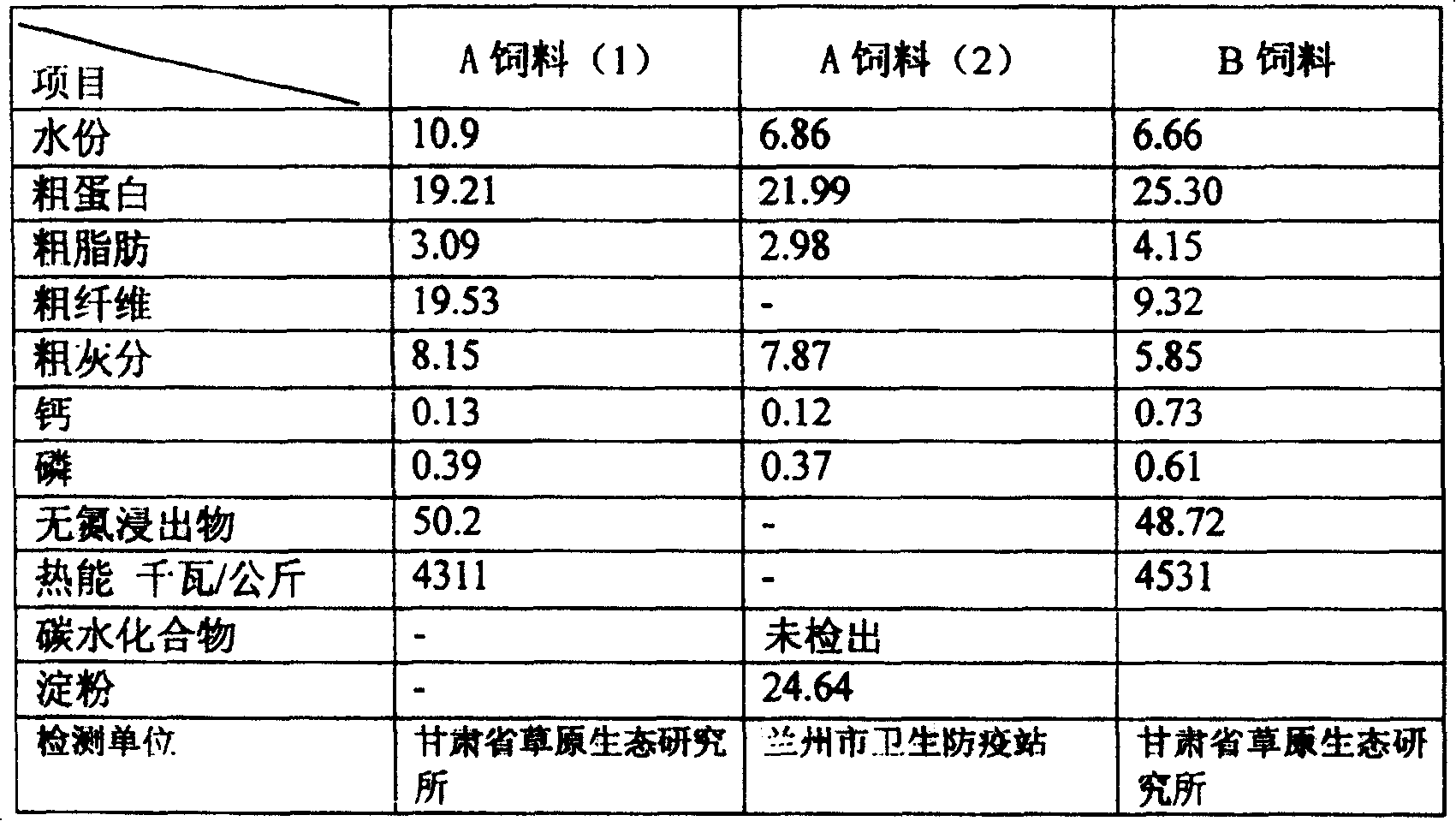

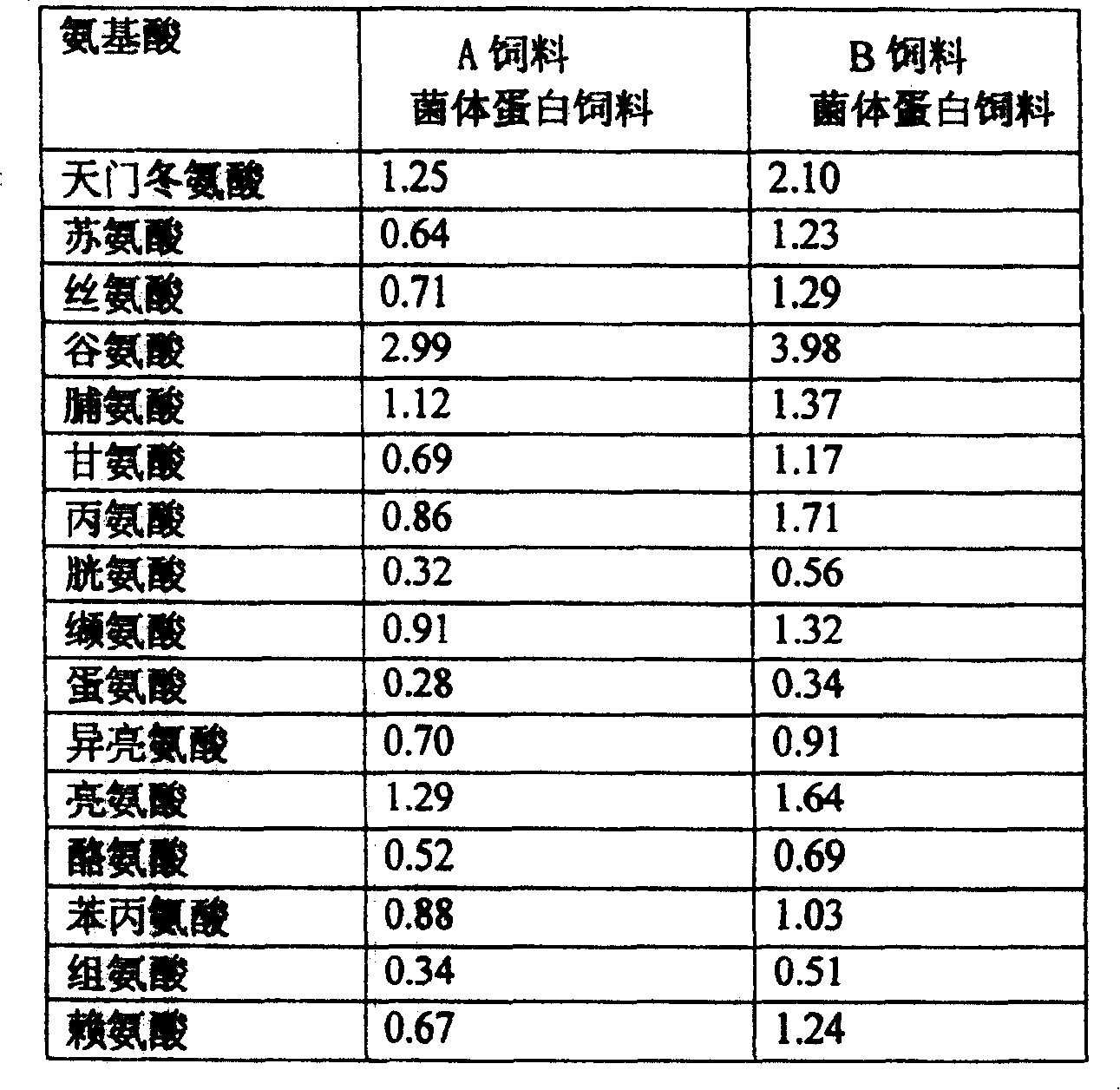

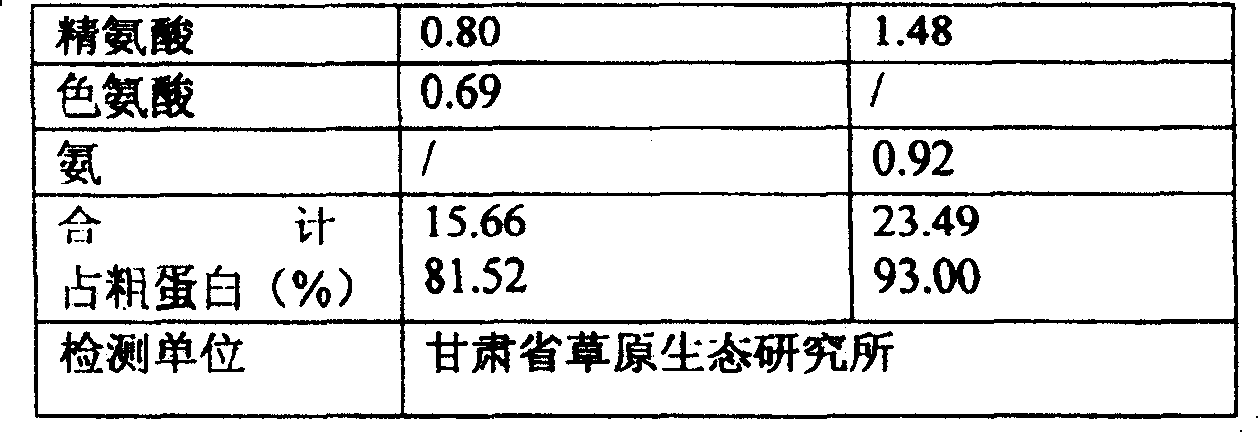

Embodiment 1

[0074] Example 1: Take 2000kg of fresh brewer's grains with 65% moisture content and add 0.5% H 2 SO 4 The processed corn cob flour, bran, and corn flour, in which the weight ratio of corn cob flour: bran: corn flour is 2:1:0.5, and 4% ammonium sulfate and 3% urea relative to the dry matter are added. After mixing well , Adjust the water content of the solid fermentation material to 45%, adjust the pH value to 5.5 with 1% lime water, and then add 12% of the total dry material to the mixture of Geotrichum, Candida and Rhizopus, Geotrichum candidum The weight ratio of Candida to Rhizopus is 55% of Geotrichum candida, 35% of Candida and 10% of Rhizopus. After fully mixing and mixing, the product is stacked on the ground when the temperature reaches 32°C, with a thickness of 10cm, and fermented at room temperature 32°C for 18 hours. The crude protein of the product can reach 21.99%, and the amino acid accounts for 81.52% of the crude protein.

Embodiment 2

[0075] Example 2: Take 2000kg of fresh brewer's grains with 75% moisture content and add 1% H 2 SO 4 The processed corn cob flour, bran, and corn flour, in which the weight ratio of corn cob flour: bran: corn flour is 4:3:1, and 2% ammonium sulfate and 1% urea relative to the dry matter are added to adjust the solid fermentation material The moisture content is 55%. After mixing well, adjust the pH value to 6.5 with 1% lime water, and then add 8% of the total dry material to the mixture of Geotrichum, Candida and Rhizopus, Geotrichum candidum The weight ratio of Candida to Rhizopus is 65% of Geotrichum candida, 30% of Candida and Rhizopus 5%. After fully mixing and mixing, the product is stacked on the ground when the temperature reaches 28°C, and the thickness is 15cm. After fermentation and culture at room temperature 28°C for 24 hours, the crude protein of the product can reach 21.99%, and the amino acid accounts for 81.52% of the crude protein.

Embodiment 3

[0076] Example 3: Take 3000kg of brewer's grains with 80% moisture content and add 1.5% H 2 SO 4 The processed corn stalk meal is steamed, and bran and corn flour are added. The weight ratio of corn stalk meal: bran: corn flour is 2:1:0. After fully mixing, adjust the solid fermentation material to 45% moisture. Adjust the pH to 5.5 with 1% lime water, and then add 9% of the total dry material to the mixture of Geotrichum, Candida and Rhizopus. The weight ratio of Geotrichum candidum, Candida and Rhizopus is white ground Mold 65%, Candida 30%, Rhizopus 5%, stir and mix well, stack it until the temperature rises to 35°C, spread it on the ground, with a thickness of 10cm, fermented at room temperature 32°C for 20 hours, the product is coarse The protein can reach 20.58%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com