Technique and structure for making convex

A manufacturing process and bump technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems that cannot be overcome by known technologies, weak mechanical strength, and difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

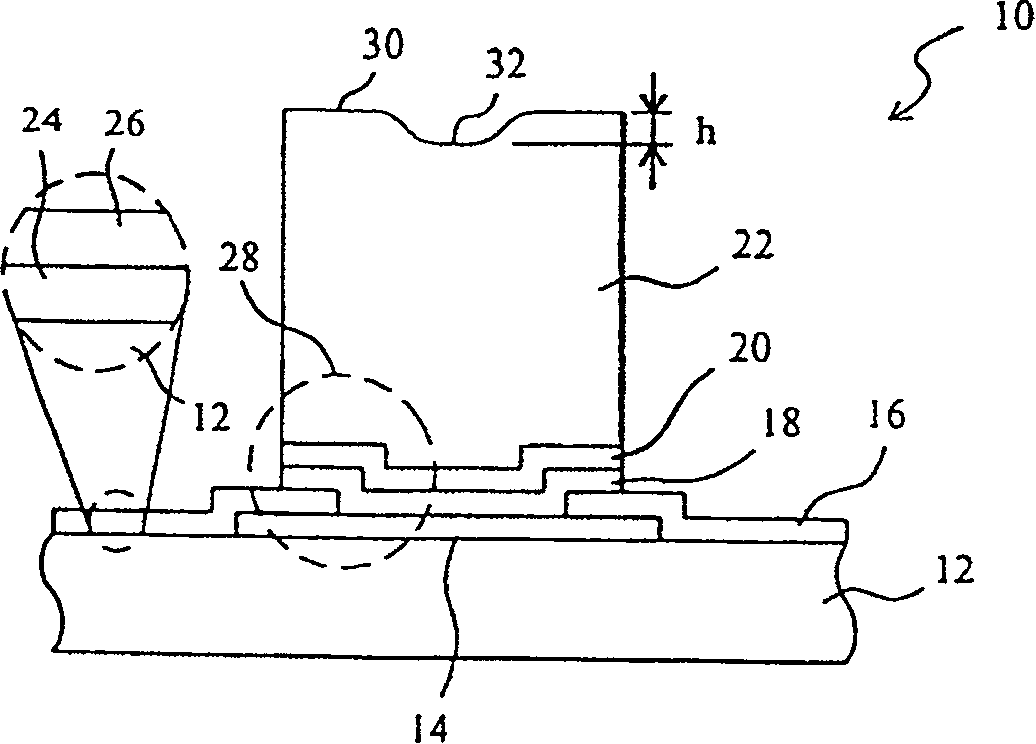

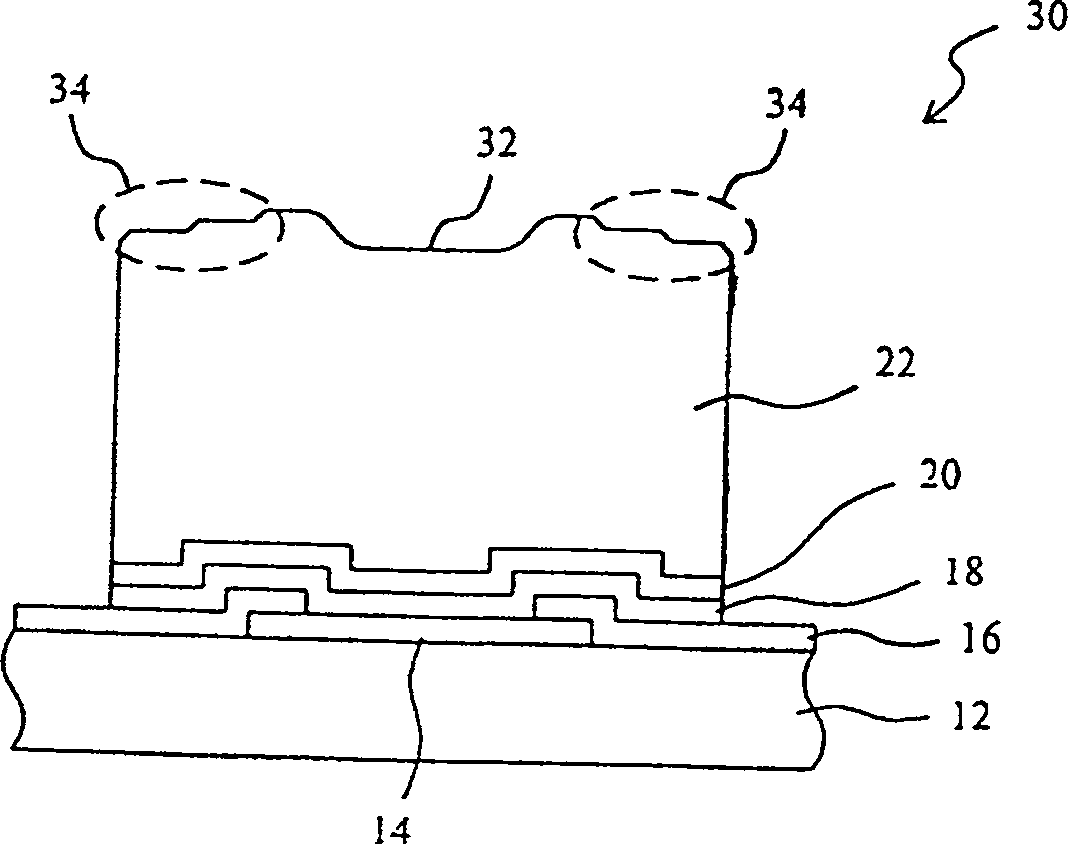

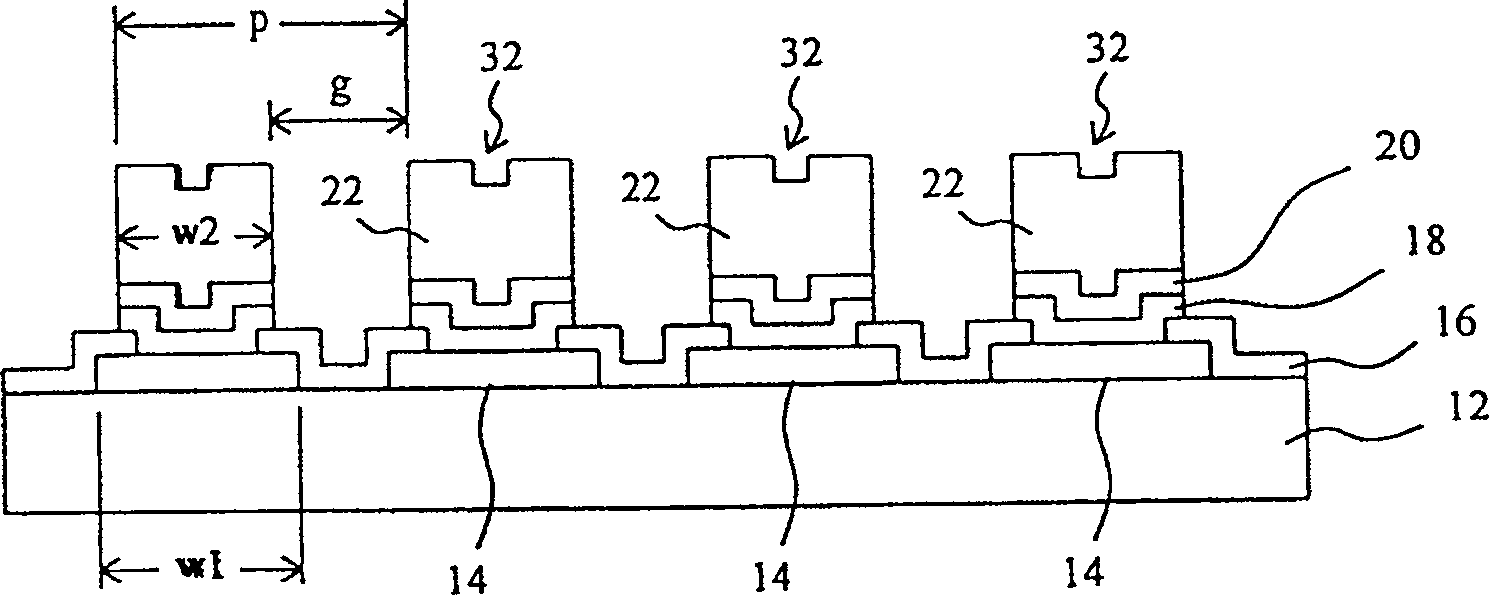

[0070] According to the present invention, a gold bump structure 60 such as Figure 6A and Figure 6B As shown, its top view is as Figure 7A and Figure 7B as shown, Figure 6A is a cross-sectional view in the X direction, Figure 6B is a cross-sectional view in the Y direction. refer to Figure 6A and Figure 6B , in the bump structure 60, the protective layer 64 with a planarized surface covers the bonding pad 62 of the substrate 12, the UBM18 and the gold film 20 are stacked on the bonding pad 62 and the protective layer 64, and the gold bump 66 is on the gold film 20 superior. The bonding pad 62 is made of aluminum, aluminum alloy, or other highly conductive metal or alloy. The protective layer 64 includes one or more layers of silicon dioxide, silicon nitride, or other highly chemically resistant materials or a combination thereof, to protect the circuitry in the underlying substrate 12 . UBM18 is mainly used to protect the bonding pad 62 to prevent various chem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com