Nitrogen-cycle engineering plastic air current and fluidized bed drying method

A technology of fluidized bed drying and airflow drying, which is applied in the direction of drying solid materials, drying gas arrangement, heating to dry solid materials, etc. It can solve problems such as dust explosion and monomer combustion, so as to avoid pollution, prevent pollution, and improve drying. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

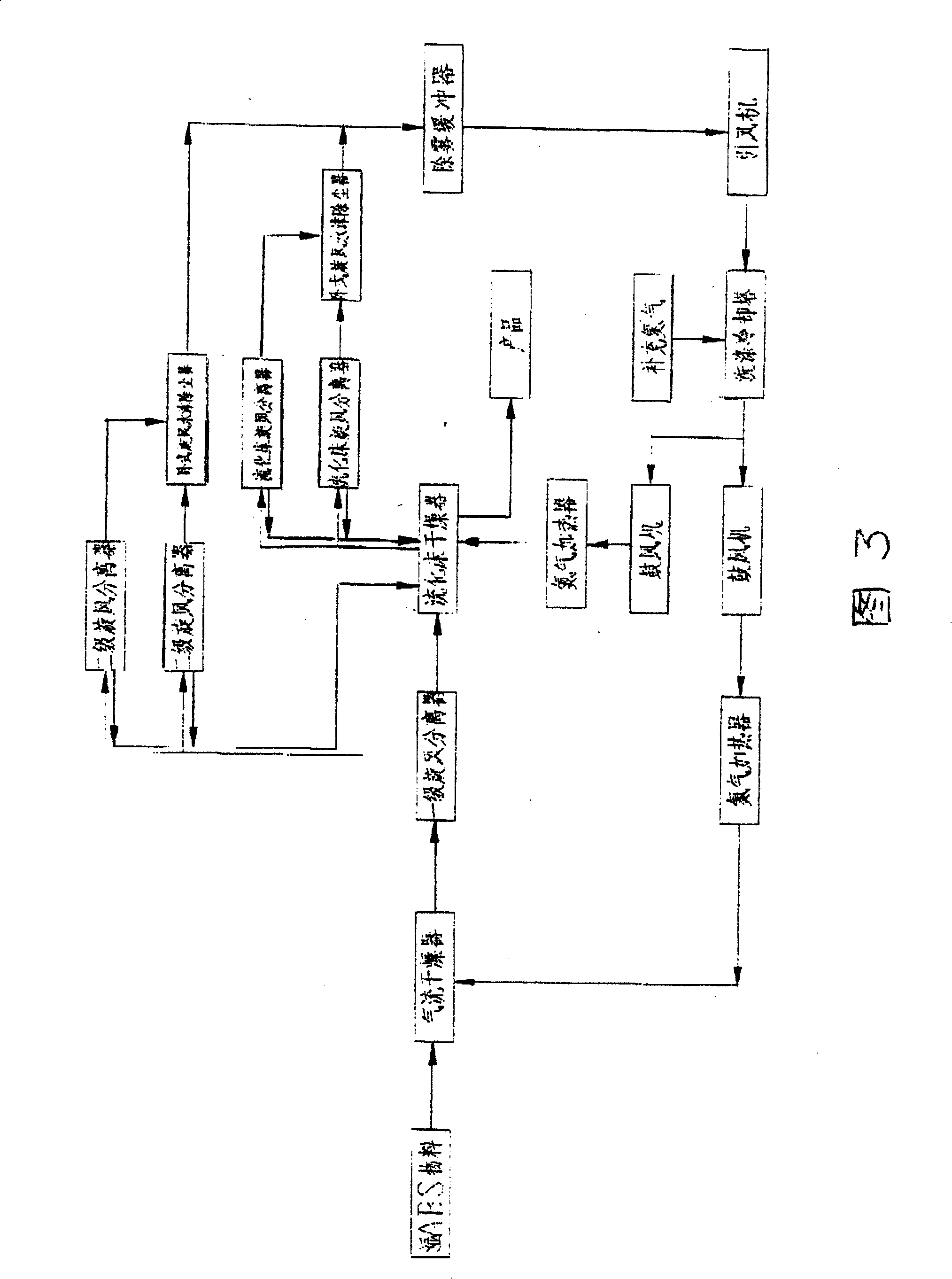

Method used

Image

Examples

Embodiment 1

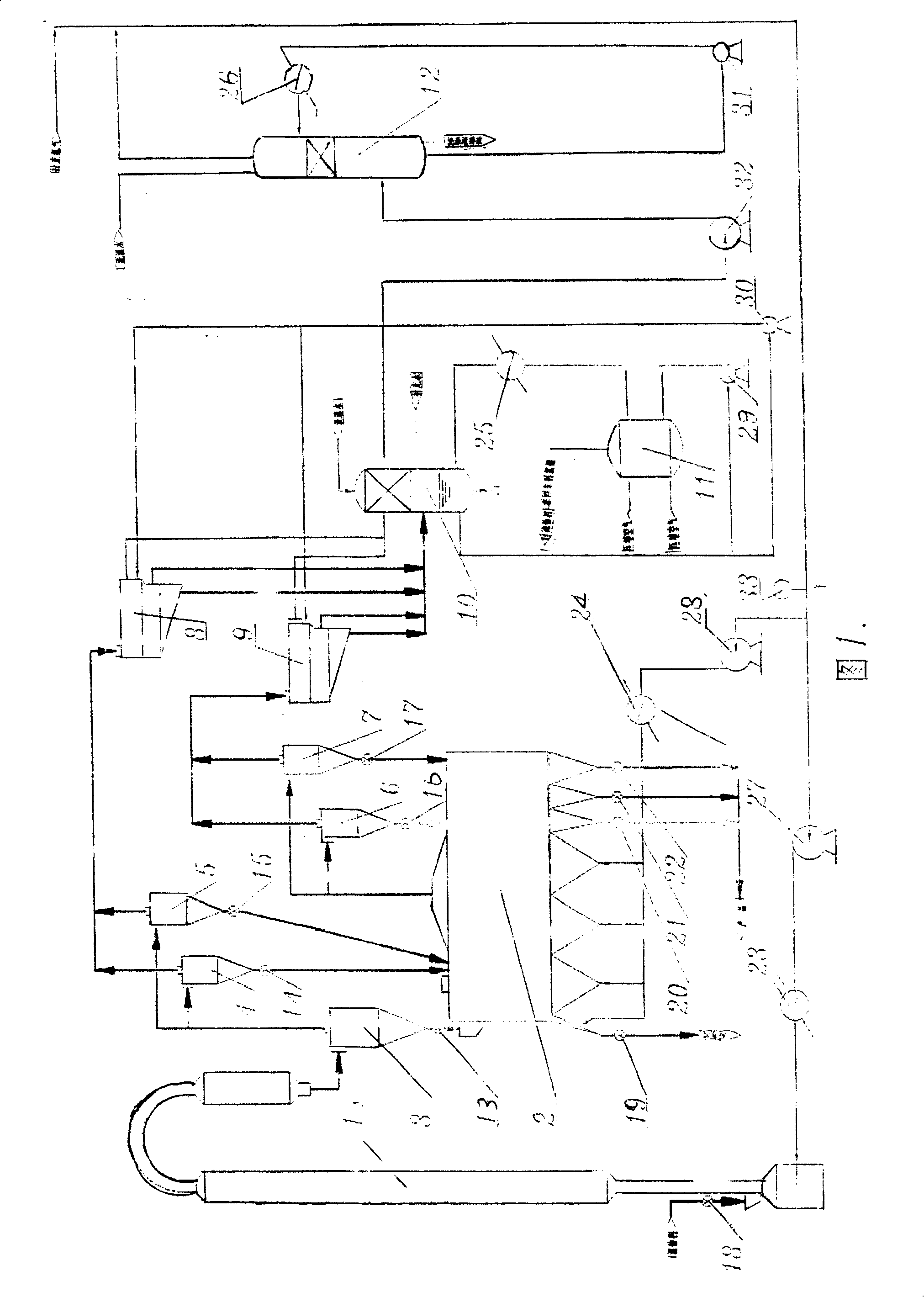

[0031] Example 1, the ABS wet powder is evenly added to the airflow dryer 1 through the feeding valve 18, and in the airflow dryer 1, the wet powder is fluidized by circulating hot nitrogen, dried, and transported to the primary cyclone separator 3 , to complete the first-level airflow drying. The function of the cyclone separator 3 is to separate the circulating nitrogen from the solid powder. After passing through the primary cyclone separator 3, most of the powder material is captured. At this time, the moisture content of the powder material in the primary cyclone separator 3 reaches 5 -15% (wt). The powder separated by the primary cyclone separator 3 enters the fluidized bed dryer 2 through the cyclone discharge valve 13 . The cyclone unloading valve has the function of keeping the seal when unloading. The discharge gas from the primary cyclone separator 3 is further separated by two secondary cyclone separators 4 and 5, and the powder is fed into the fluidized bed drye...

Embodiment 2

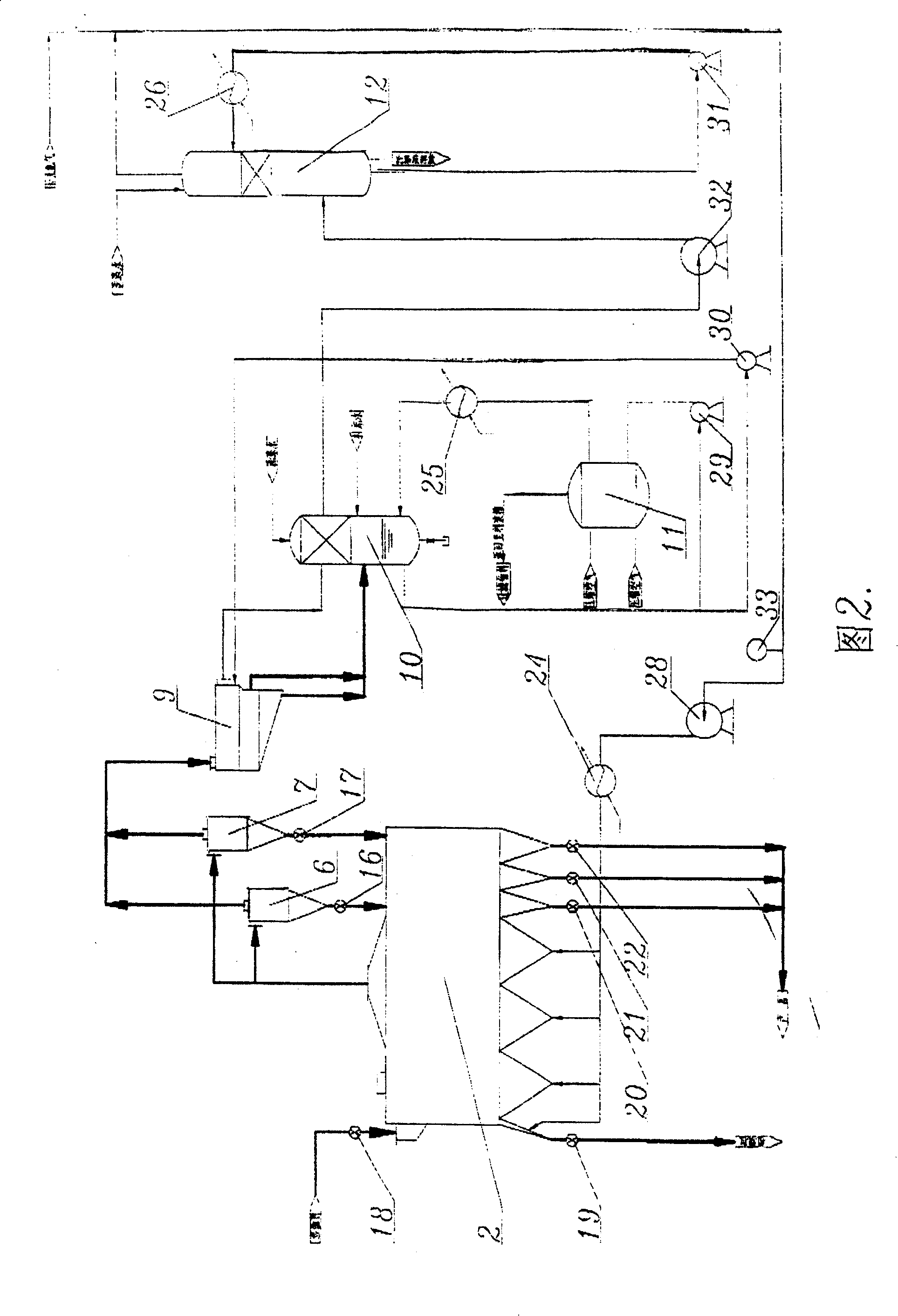

[0038] Embodiment 2, ABS wet powder is uniformly fed into the fluidized bed dryer 2 through the feed valve 18 . The ABS powder enters the fluidized bed dryer 2, and under the action of the bottom of the fluidized bed agitator and hot nitrogen, it is rapidly fluidized to form a fluidized bed layer, and the wet powder gradually moves from the inlet end to the discharge end. During the process, it is gradually heated and dried by hot nitrogen gas. When the ABS powder leaves the fluidized bed dryer 2, the moisture content reaches below 1% (dry basis) and becomes a qualified product. The fine particles entrained by the hot nitrogen in the fluidized bed are separated by the fluidized bed cyclone separator 6 and the cyclone separator 7, and then returned to the fluidized bed dryer 2 through the cyclone discharge valve 16 and the cyclone discharge valve 17. The materials pass through the fluidized bed dryer unloading valve 20, unloading valve 21 and unloading valve 22 together into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com