Method for producing charcoal by using shell of mountain walnut and charcoal making device

A technology of hickory shell and charcoal formation, which is applied in special forms of dry distillation, petroleum industry, coke oven, etc., to achieve the effects of protecting the ecological environment, excellent quality, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

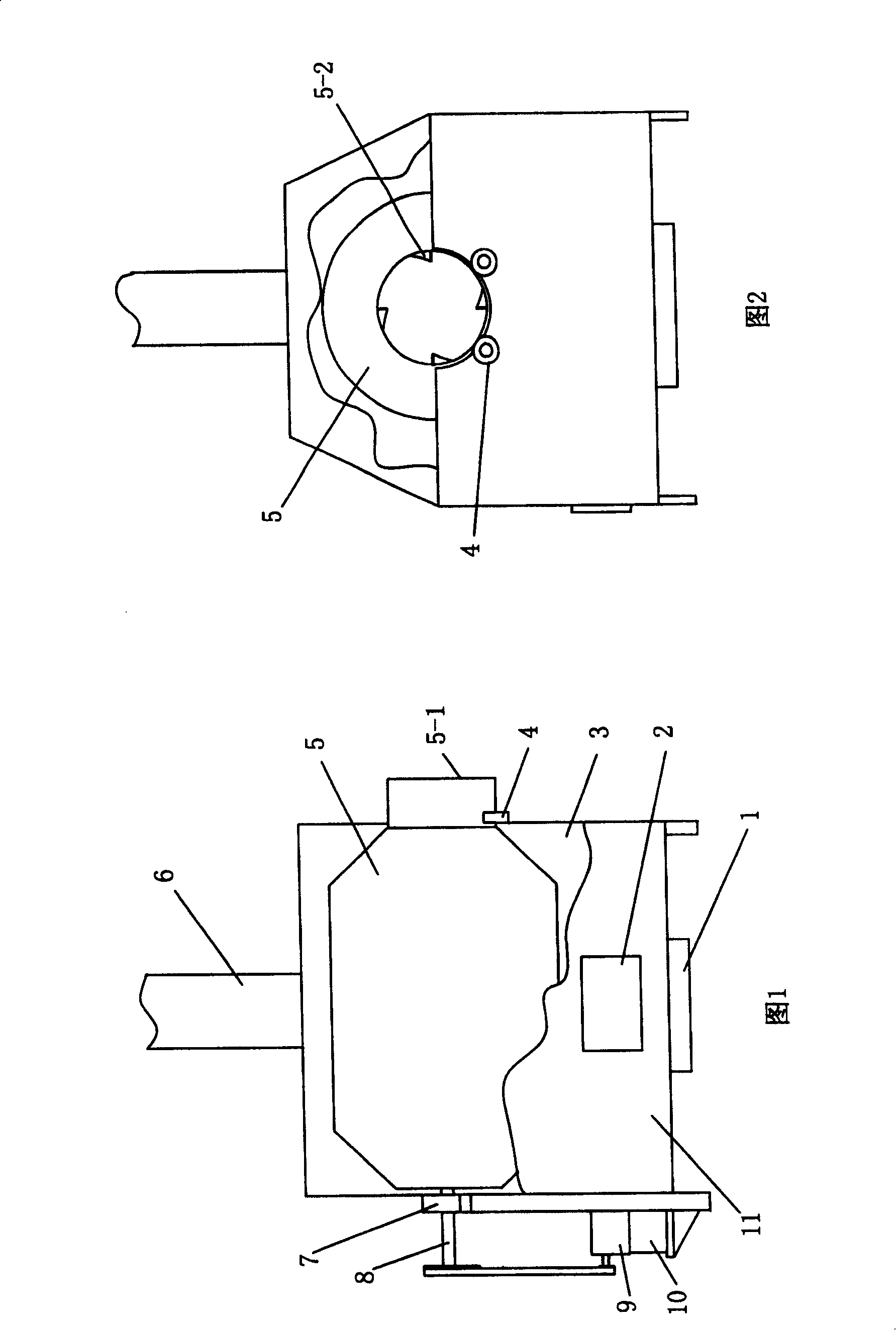

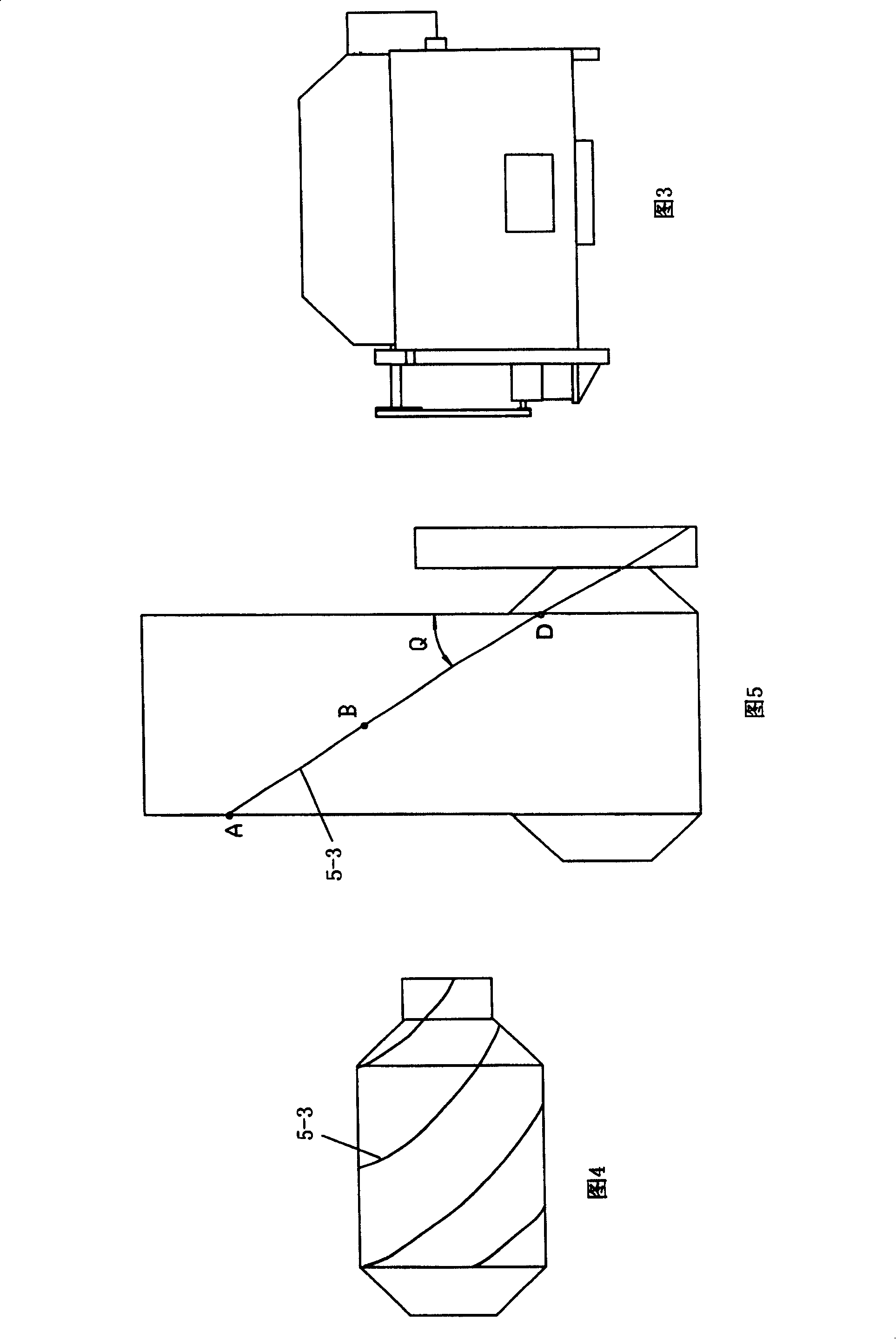

[0019] The method of making pecan shells into charcoal, put the pecan shells into a heated metal pot and stir fry, the heat will be transferred from the metal pot to the pecan shells, the purpose of stirring is to make the pecan shells heated evenly; fry for a certain period of time Finally, the hickory shell first emits steam, then the hickory shell begins to carbonize and emit black smoke; when the carbonization is basically completed, the black smoke begins to turn into white smoke, and when the white smoke basically disappears, the carbonization is completed, and it can be taken out of the pot.

[0020] There is no special requirement for the temperature during frying, but it needs to be above 200°C. The carbonization time is shorter when the temperature is higher, and the carbonization time is longer when the temperature is lower, and the carbonization process can be completed; generally speaking, the heating temperature of hickory nut shells is more appropriate at 200-600...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com