Gas-sensitive conducting composite material of aqueous polyurethane group and preparation method

A conductive composite material and water-based polyurethane technology are applied in the field of water-based polyurethane-based gas-sensing conductive composite materials and their preparation to achieve excellent electrical conductivity and reduce the effect of percolation value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

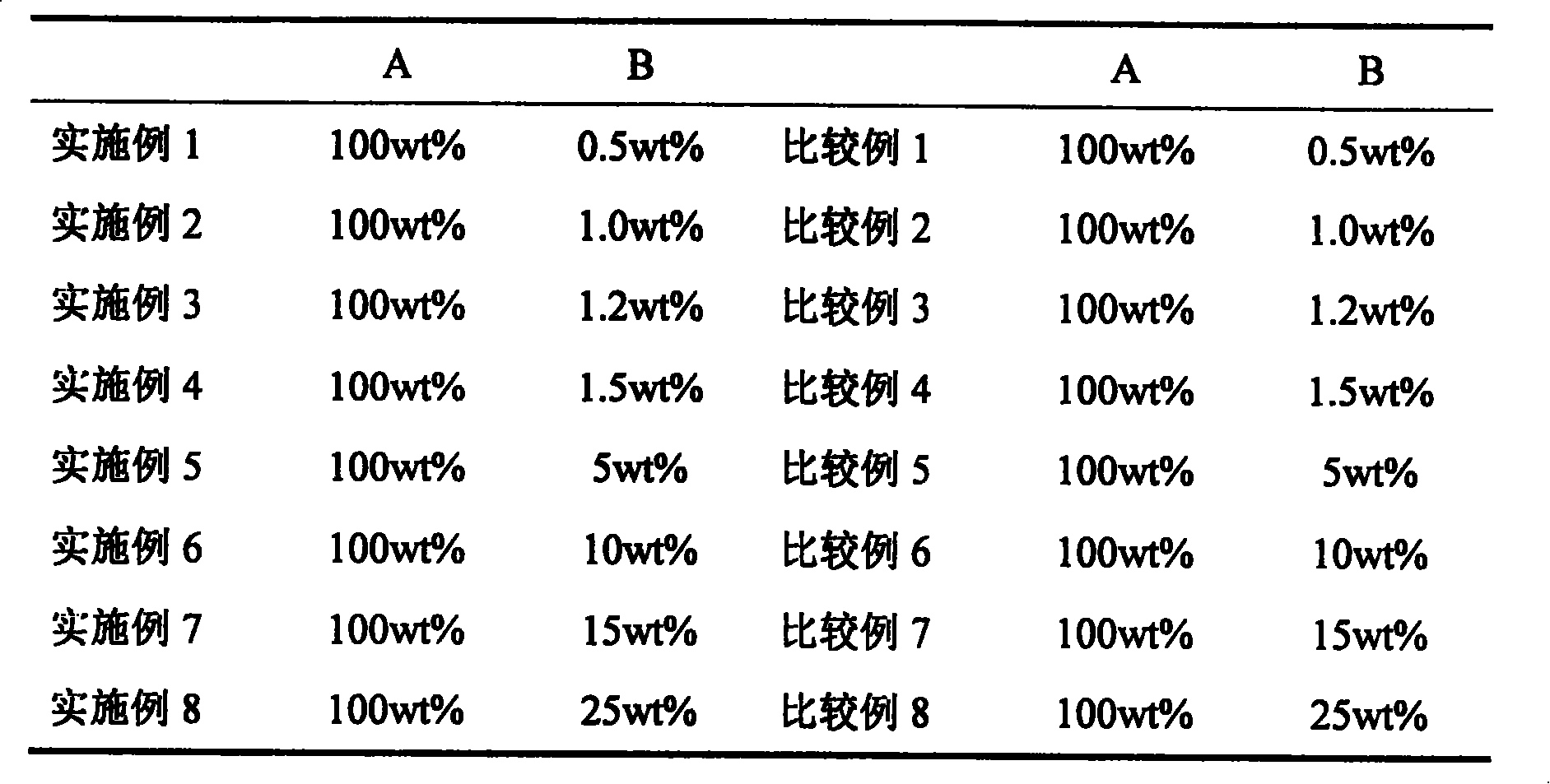

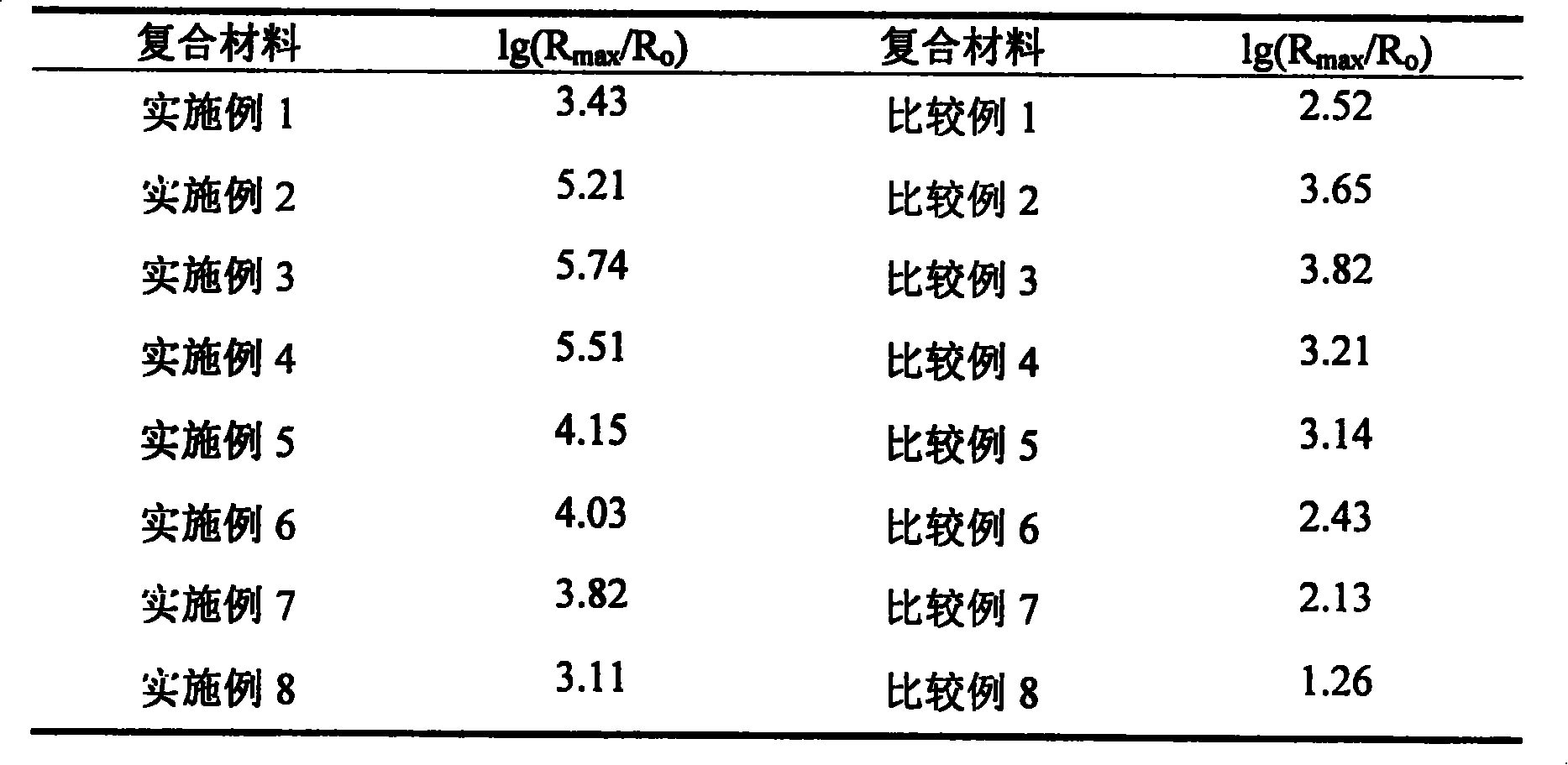

[0023] The ratio table 1 of embodiment 1~8, its preparation method concrete steps are as follows:

[0024] 1. Synthesis of permanent polyurethane prepolymer: Add the dried oligomer polyol and diisocyanate into the reaction kettle according to the ratio of 6:1 to 2:1, add the catalyst, and react at 70-120°C 8-14 hours, the amount of catalyst used is 0.5% of the amount of polyol.

[0025] 2. Add pre-dried conductive carbon black to the reaction kettle and continue to react for 8-14 hours.

[0026] 3. Cool down to below 50°C, add neutralizing agent triethylamine to neutralize for 1 hour

[0027] 4. Add deionized water for emulsification, and at the same time add chain extender ethylenediamine for chain extension reaction for 3 to 6 hours.

[0028] 5. Emulsion discharge is filtered to obtain composite material emulsion, which is stored for later use.

[0029] 6. The emulsion is coated on the electrode plate and dried at room temperature for 2 weeks to obtain a composite materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com