Method and device for producing gear plates for continuously variable gearbox

A technology of stepless adjustment and speed change wheel, which is applied in hoisting devices, portable lifting devices, manufacturing tools, etc., to achieve the effect of reducing surface roughness, reducing bonding force, and uniform surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

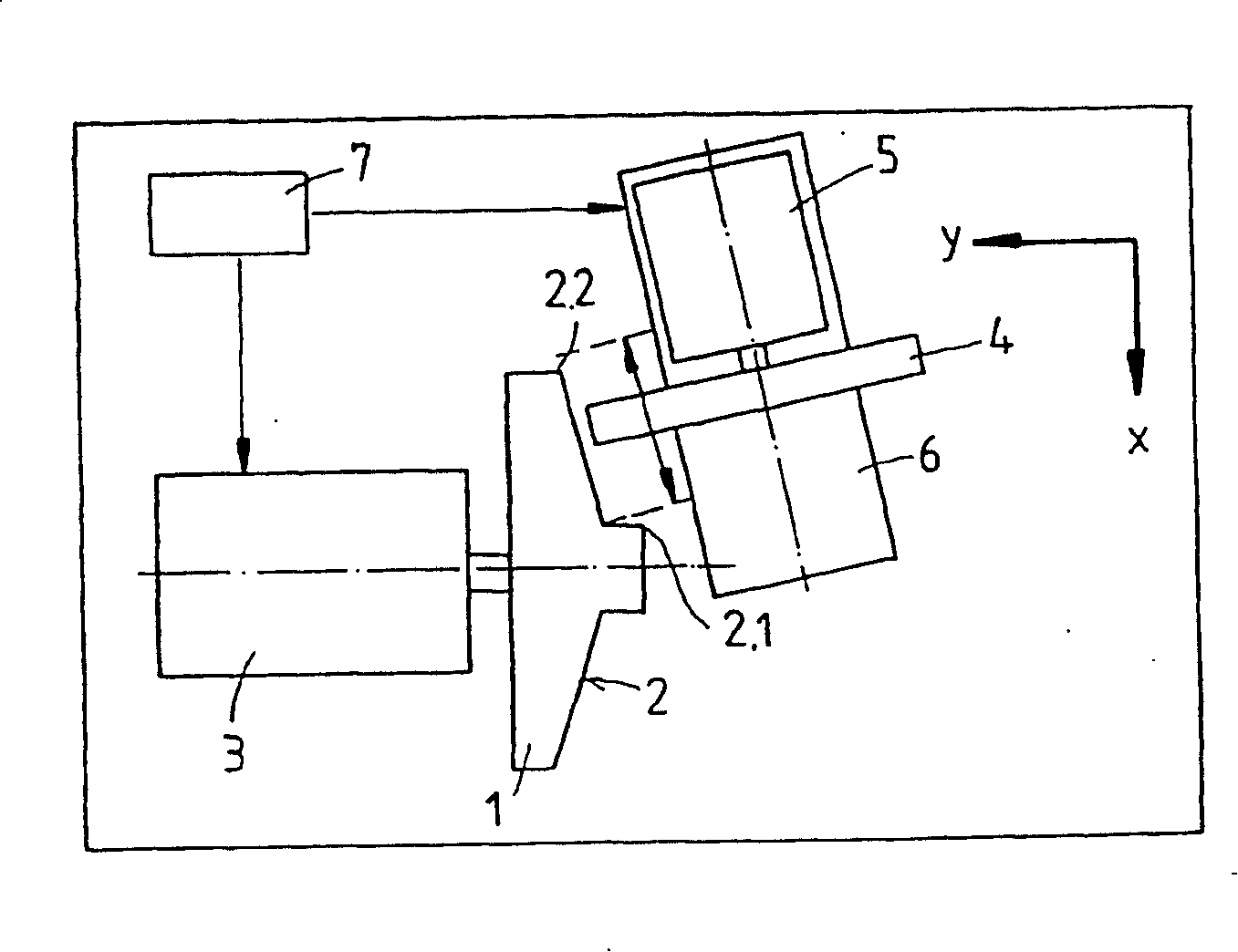

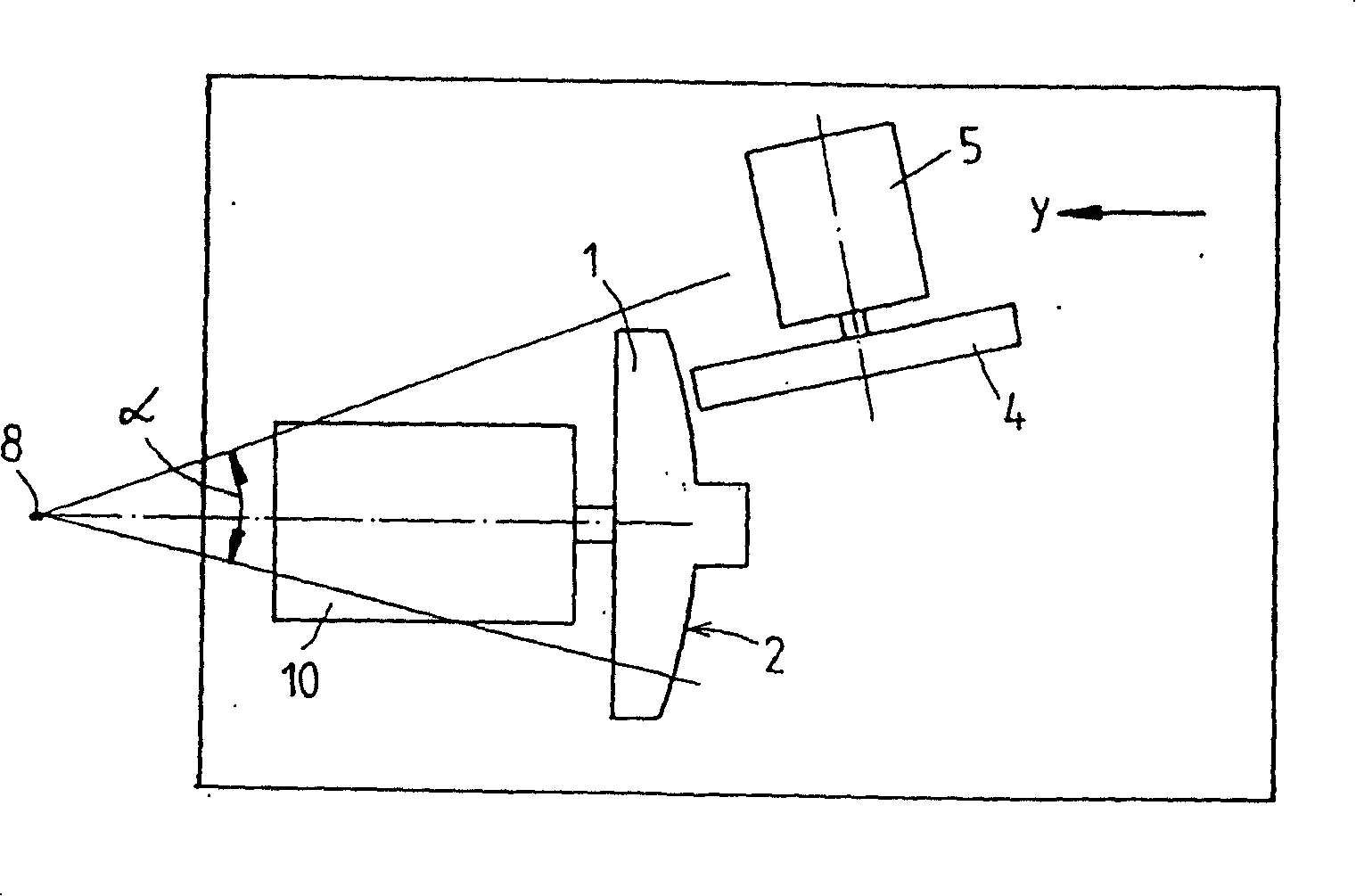

[0026] figure 1A top view of the grinding device of the present invention is briefly shown. A gear wheel with a conical surface 2 as workpiece 1 is clamped on a workpiece shaft 3 . The shift wheel 1 has a conical drive surface 2, ie the shift wheel is curved in only one direction. It is of course also possible to have a curved shape in both directions. A grinding wheel 4 is arranged on the grinding wheel spindle 5 for grinding the conical drive surface 2 of the transmission wheel 1 . The grinding wheel 4 and the grinding wheel axle 5 are arranged on the grinding wheel axle seat 6, so that the grinding wheel 4 can swing back and forth when the surface 2 is ground. For this purpose, a control device 7 is additionally provided, by means of which the rotational speed of the workpiece spindle 3 and the reciprocating pivoting of the grinding wheel 4 are controlled. When grinding the transmission surface of the transmission wheel 1, the grinding wheel 4 swings back and forth betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com