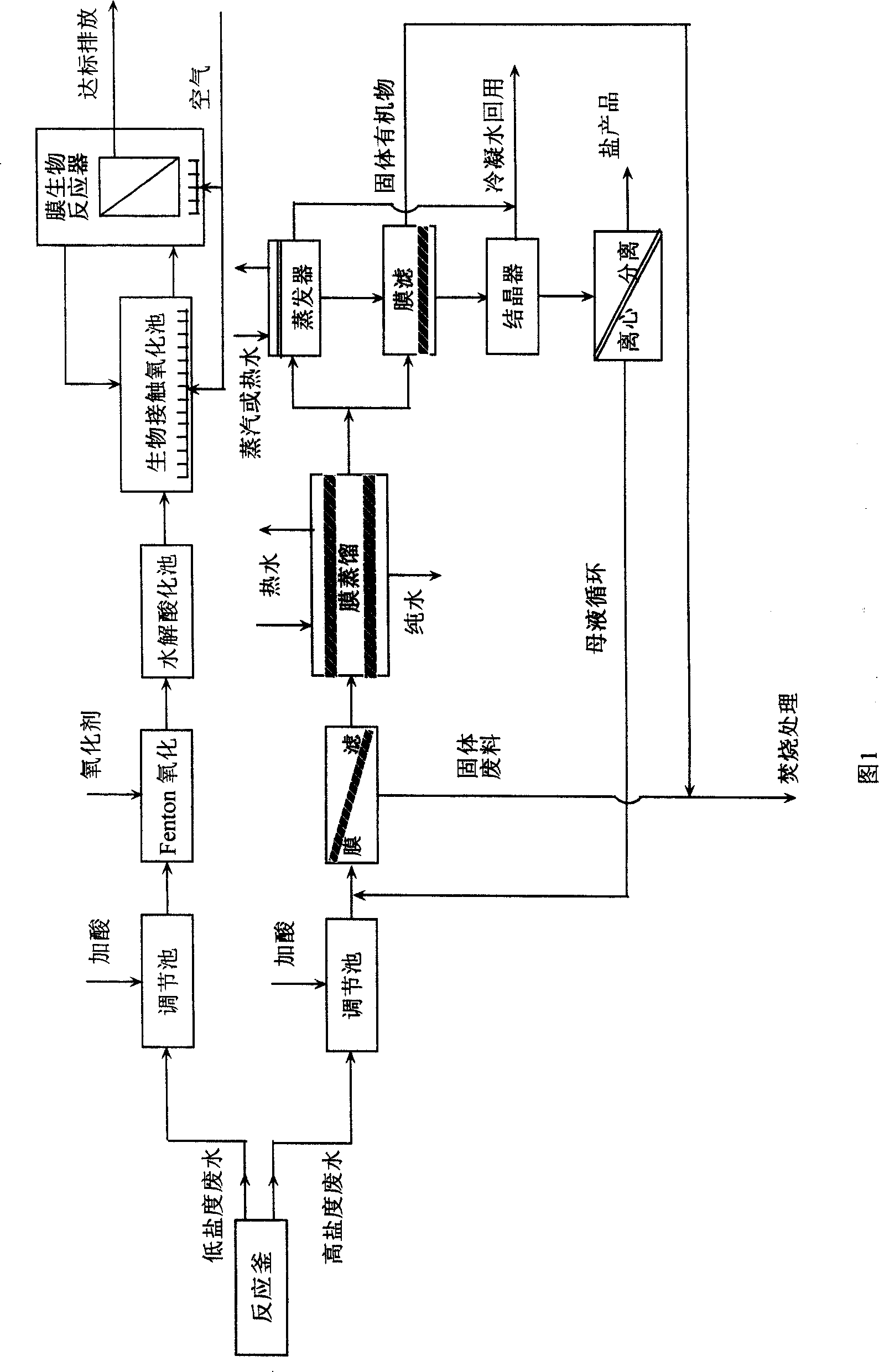

High-salt epoxy resin production waste-water film integrated salt recovery and biochemical treatment method

A technology of salt epoxy resin and production wastewater, applied in the field of industrial wastewater treatment, can solve the problems of enterprise acceptance, high energy consumption and high operating cost, and achieve the effects of creating economic benefits, strengthening treatment effects, saving energy and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

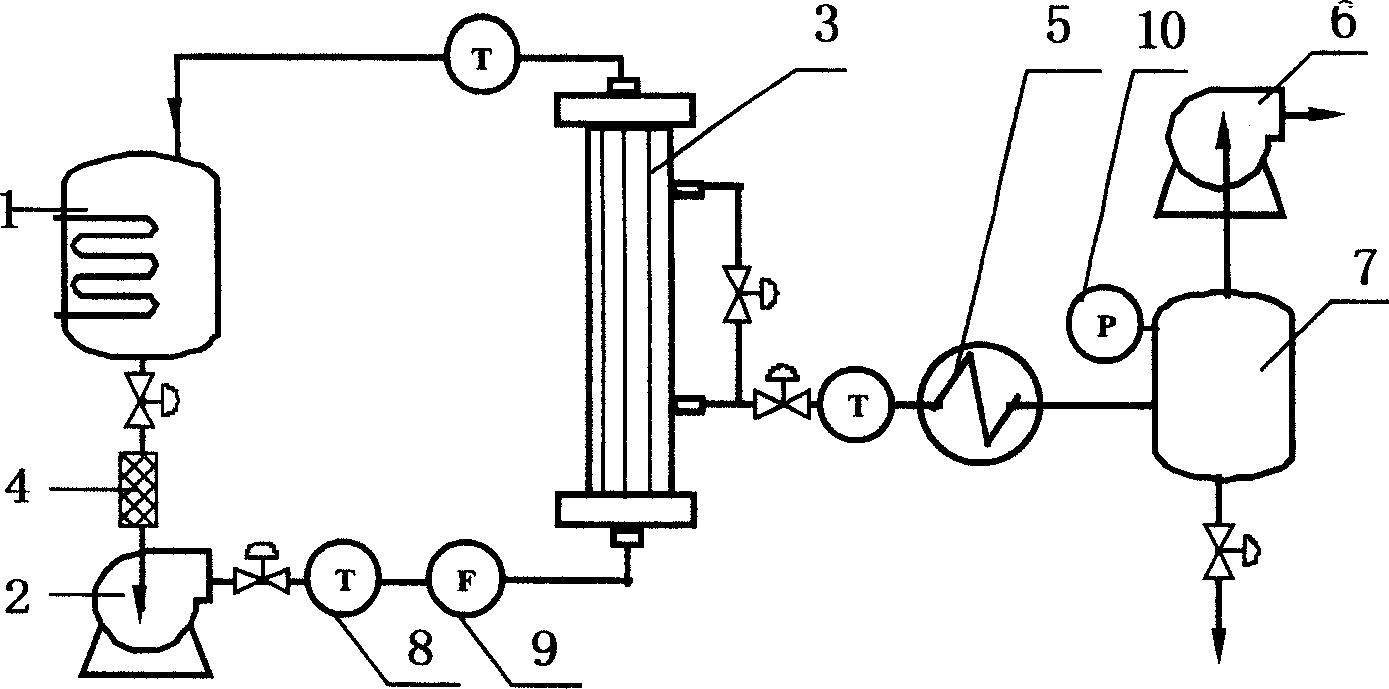

[0030] Using self-made membrane modules and the membrane distillation device designed by the present invention, a small test experiment was carried out on the treatment of epoxy resin production washing wastewater in a chemical factory in Huangshan, Anhui.

[0031] 1) In the production process of epoxy resin, the first three production washing wastewaters are high-salinity wastewater with a salt content of 10%wt and a COD of 7000mg / L; 1000mg / L low-salinity wastewater;

[0032]2) The high-salinity wastewater is adjusted to neutrality in the neutralization tank, and is sent to a tubular microporous membrane filter by a booster pump to filter or remove precipitated organic matter through natural sedimentation;

[0033] 3) After filtration, the wastewater clear liquid is circulated into the membrane distillation device under normal pressure for concentration and dehydration. The vacuum degree of the membrane permeation side of the membrane distillation device is 0.4ba; the feed te...

Embodiment 2

[0036] Using self-made membrane modules and the membrane distillation device designed by the present invention, a small test experiment was carried out on the treatment of epoxy resin production washing wastewater in a chemical factory in Huangshan, Anhui.

[0037] 1) In the production process of epoxy resin, the first three production washing wastewaters are high-salinity wastewater with a salt content of 30%wt and a COD of 15000mg / L; 1500mg / L low-salinity wastewater;

[0038] 2) The high-salinity wastewater is adjusted to neutrality in the neutralization tank, and is sent to a tubular microporous membrane filter by a booster pump to filter or remove precipitated organic matter through natural sedimentation;

[0039] 3) After filtration, the wastewater clear liquid is circulated into the membrane distillation device under normal pressure for concentration and dehydration. The vacuum degree of the membrane permeation side of the membrane distillation device is 0.95ba; the feed...

Embodiment 3

[0042] Using self-made membrane modules and the membrane distillation device designed by the present invention, a small test experiment was carried out on the treatment of epoxy resin production washing wastewater in a chemical factory in Huangshan, Anhui.

[0043] 1) In the production process of epoxy resin, the first three production washing wastewaters are high-salinity wastewater with a salt content of 23.3%wt and a COD of 11500mg / L; 1156mg / L low-salinity wastewater;

[0044] 2) The high-salinity wastewater is adjusted to neutrality in the neutralization tank, and is sent to a tubular microporous membrane filter by a booster pump to filter or remove precipitated organic matter through natural sedimentation;

[0045] 3) After filtration, the wastewater clear liquid is circulated into the membrane distillation device under normal pressure for concentration and dehydration. The vacuum degree of the membrane permeation side of the membrane distillation device is 0.95ba; the fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com