Synthetic fibre rope without jacket

A synthetic fiber and rope technology, applied in the direction of synthetic fiber, fiber treatment, fiber type, etc., can solve the problems of displacement or accumulation of synthetic sheath, broken rope, expensive sheath, etc., and achieve the effect of simple cost and reliable protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT

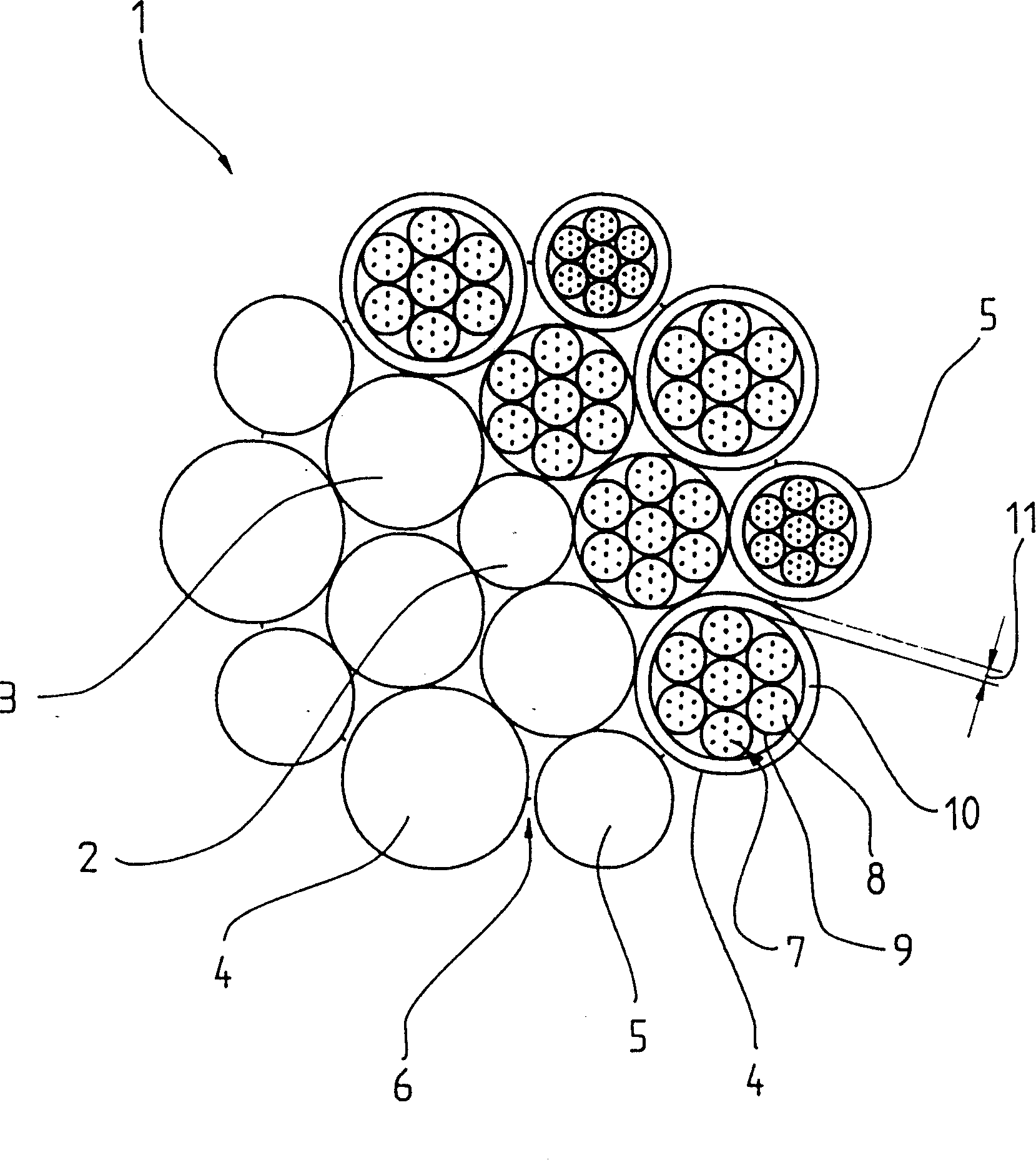

[0029] A preferred exemplary embodiment of the invention with a liquid impregnating substance is described below with reference to a drawing showing a cross-section of a rope 1 consisting of 16 strands. Five helically identical strands 3 are twisted around a central strand 2, and five thicker strands 4 and five thinner strands 5 are alternately twisted in parallel with the strands 3 to form the outermost layer 6 (also called the covering layer). The strands 2 , 4 , 5 shown in the rope 1 for carrying the load are twisted or twisted from a single bundle of aramid fibers 7 .

[0030] The strands 2, 3, 4 and 5 consist essentially of aramid threads 8 helically bonded in a polyurethane matrix. For twisting or twisting, the aramid thread 8 is treated with a protective impregnating substance, such as a polyurethane solution. The ratio of polyurethane in 2, 4, 5 per strand is jointly determined by the fatigue strength of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com