Method for determining the winding quality of a film roll

A technology of winding quality and film rolls, which is applied in the direction of winding strips, thin material handling, and sending objects, etc. It can solve the problems of not considering the characteristics of air layer compensation, the influence of film contours, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

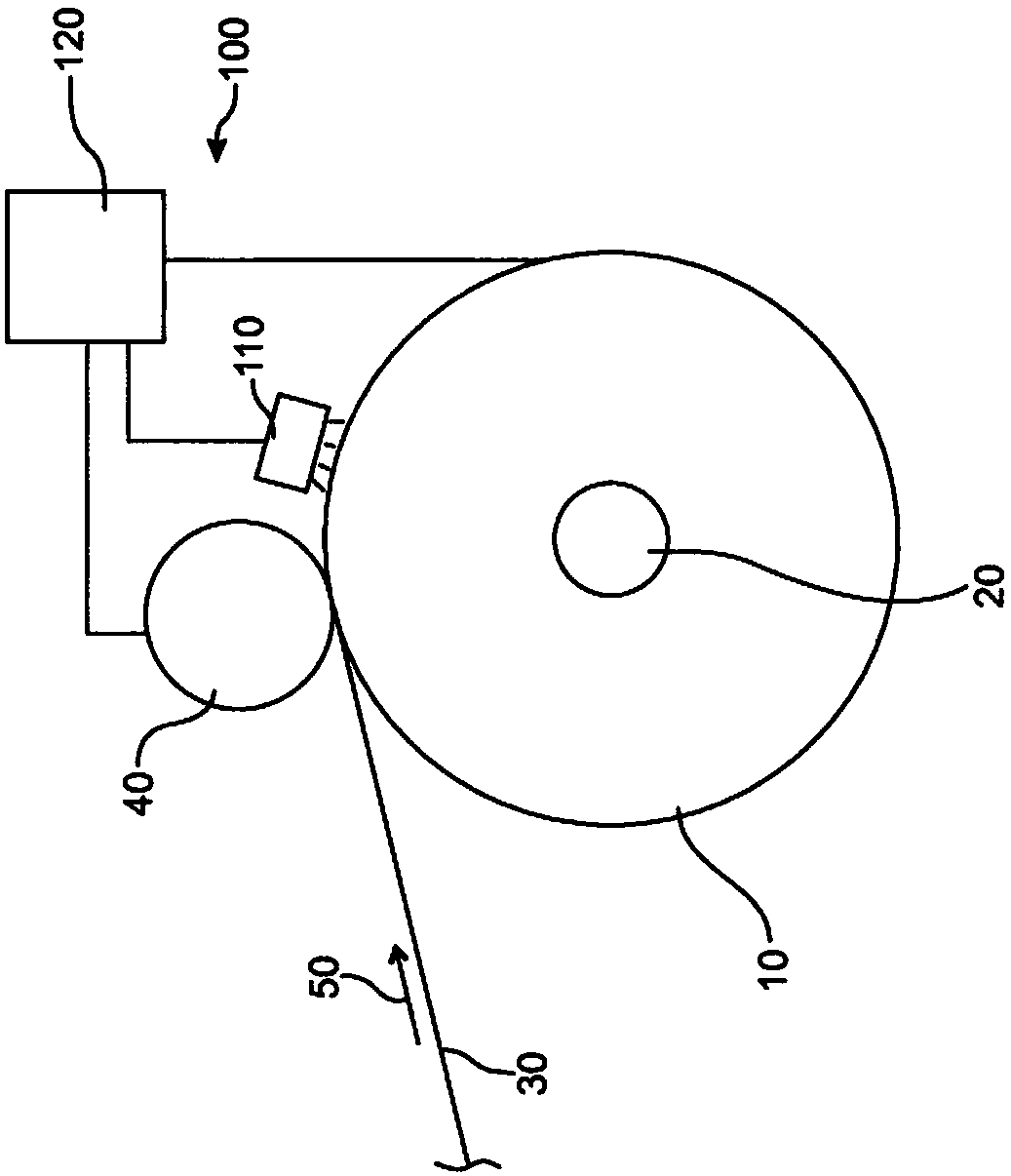

[0047] figure 1 A winding device is shown schematically with a winding roller 20 on which the film roll 10 is produced. To this end, the take-up roller 20 is rotated and the film 30 is wound up thereon. In order to be able to ensure a clean winding process, a contact roller 40 is provided which exerts a corresponding pressing force AD on the film roll.

[0048] as in figure 1 As can be seen in , a monitoring device 100 is provided. The monitoring device is equipped with a sensor device 110 and a control device 120 . The sensor device 110 is designed to determine the roll stiffness in at least the uppermost layers of the film 30 during the winding process. This determination takes place in particular contactlessly, for example by means of ultrasonic measurements. Furthermore, the control device 120 can be designed to regulate operating parameters. This is indicated by the dotted lines between the control device 120 and the winding roller 20 and the contact roller 40 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com